Film-covering liquid-coating extrusion integrated lining machine

A laminating machine and liquid coating technology, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of glass strength influence, production efficiency, long drying cycle, etc., to improve strength and anti-explosion Performance, improved production efficiency, shortened drying cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

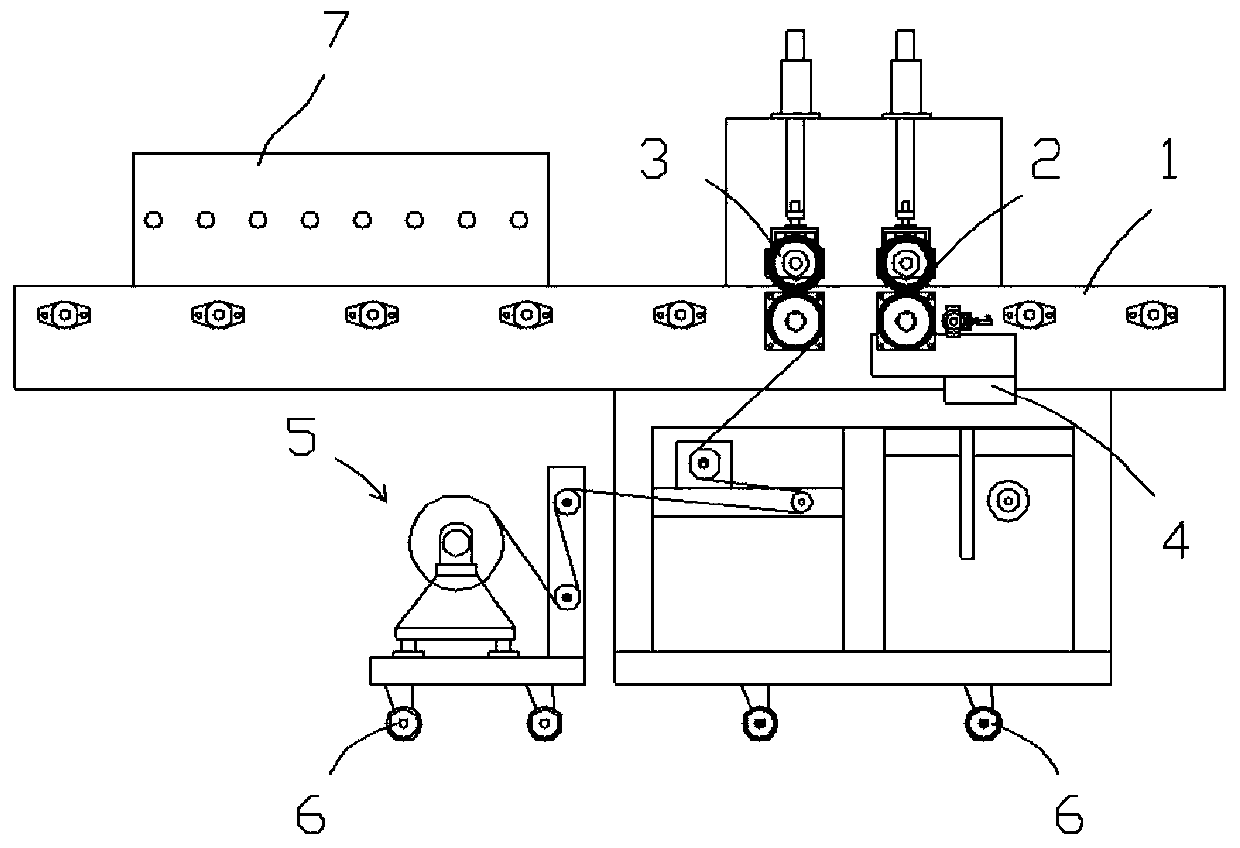

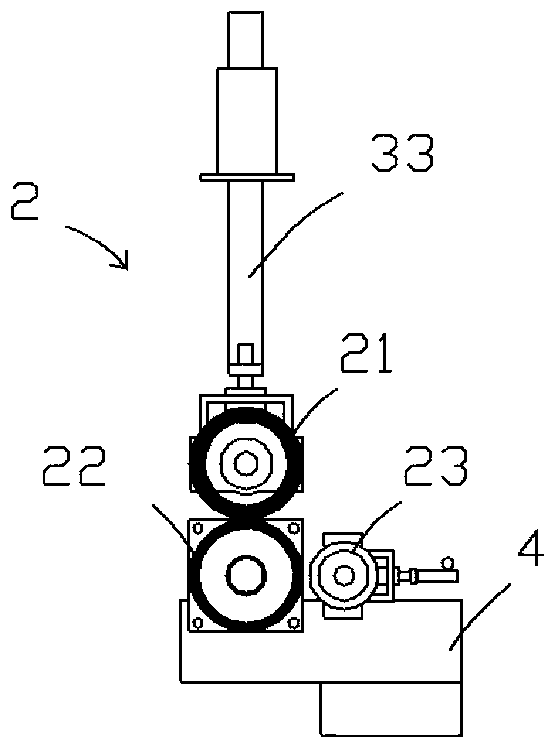

[0020] Such as Figures 1 to 5 Shown is an embodiment of a film coating liquid extrusion integrated laminating machine of the present invention, which includes a frame 1, on which a rotating roller for conveying workpieces is arranged, the rotating roller is driven by a motor, and on the frame 1 A pair of winding rollers 3 and a pair of applicator rollers 2 are provided, a UV photosensitive drying channel 7 is installed on the frame 1 at the output end of the workpiece, and a coating applicator is installed on the frame 1 below the applicator roller 2. The liquid coating box 4 , the lower part of the liquid coating roller 2 is located in the liquid coating box 4 .

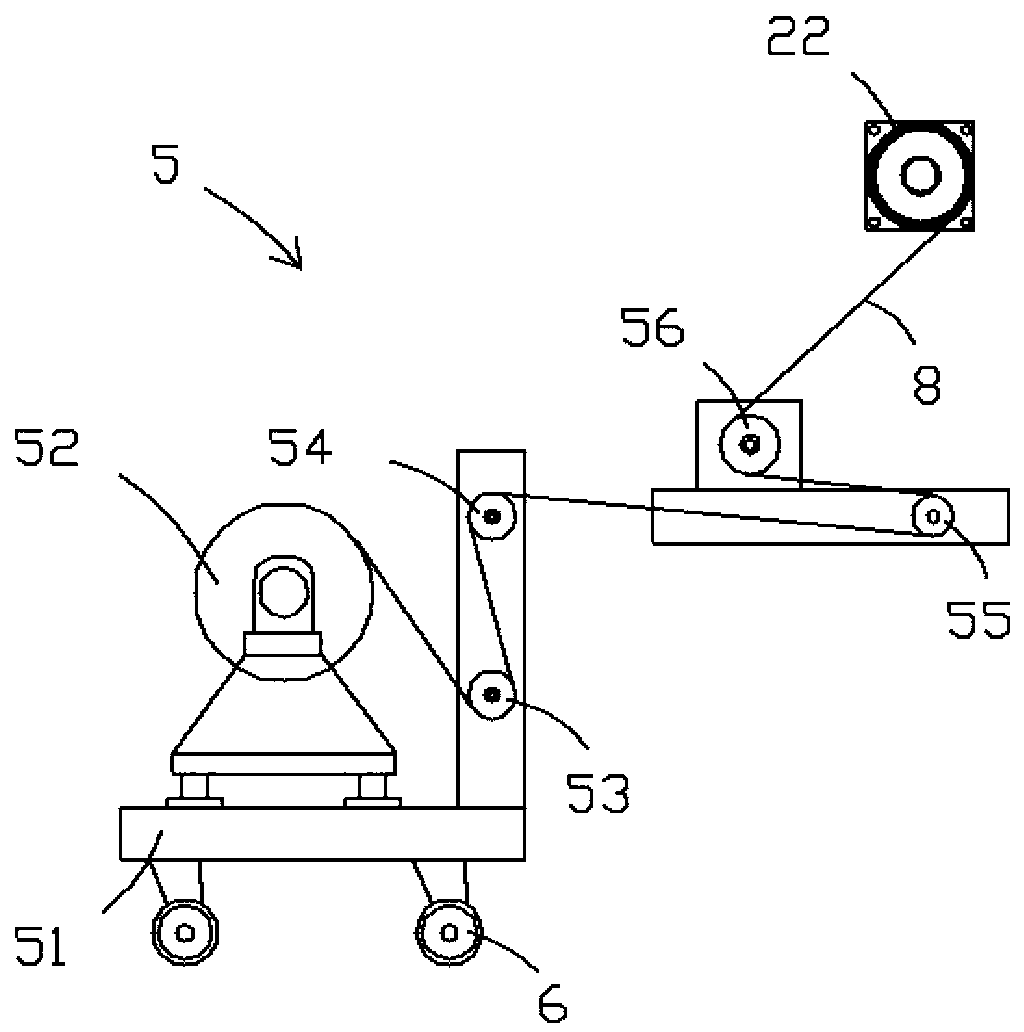

[0021] A film unwinding device 5 is arranged below the frame 1, and the film unwinding device 5 is composed of an unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com