Stacking carrying cart used for production of washing machine motors

A technology for washing machines and trolleys, applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve problems such as product damage, efficiency impact, rubbing, etc., to reduce the probability of touching, improve production efficiency, and improve the quality of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

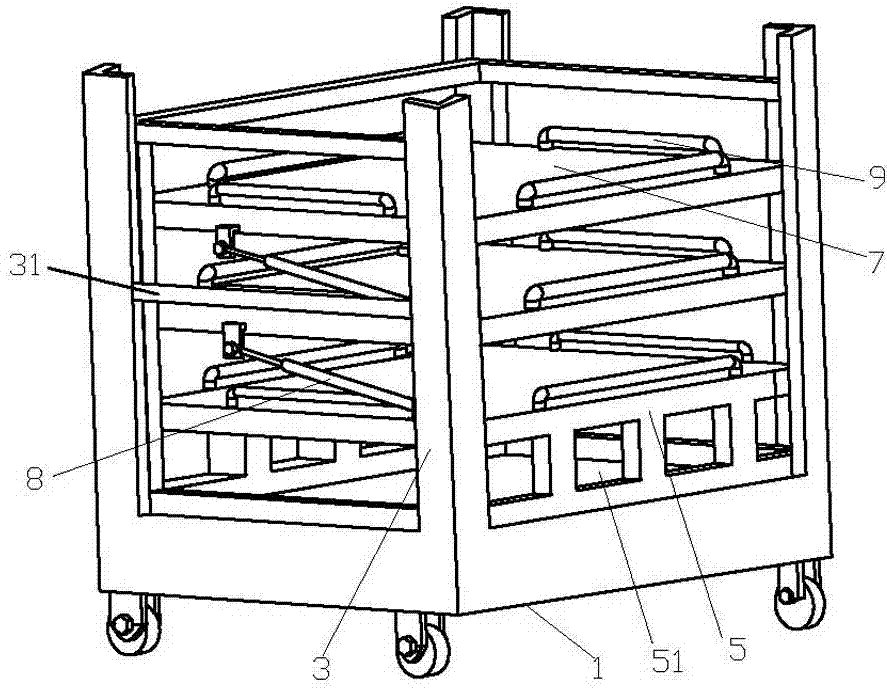

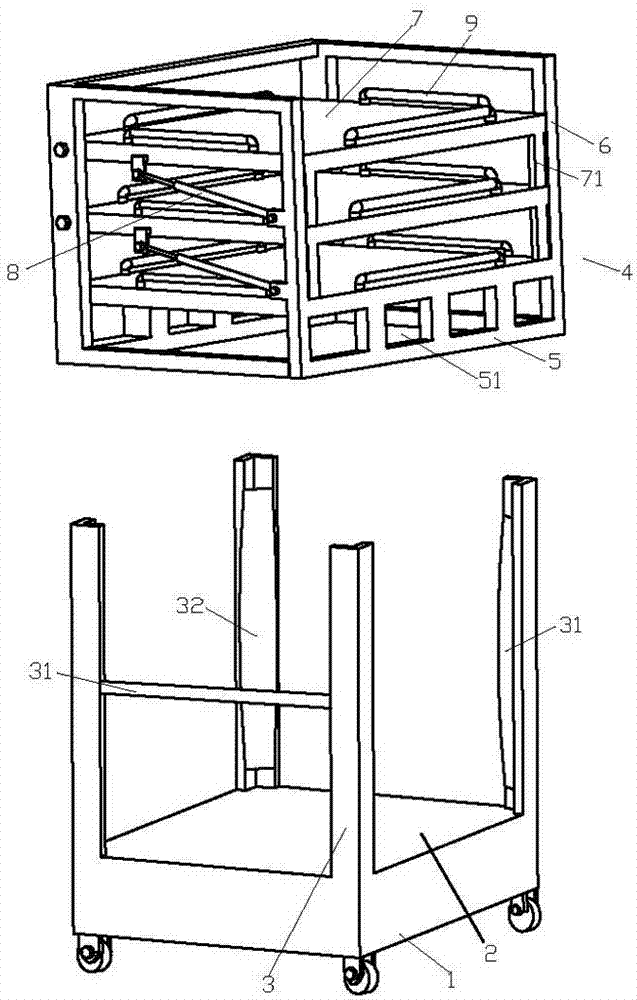

[0021] Example 1, such as figure 1 , 2 As shown, a stacking and transporting trolley for the production of washing machine motors includes a bottom mobile frame 1, casters are installed on the lower part of the bottom mobile frame 1, and a support platform 2 is provided on the upper part. The four corners of the support platform 2 are equipped with The blocking part is composed of two vertical baffles 3 connected vertically and integrally. The blocking part encloses a cubic space structure. The bottom mobile frame 1 is also equipped with a stacking compartment 4, which can be placed into a cube. In the spatial structure, the stacking box 4 includes a lifting portion 5 and a stacking stand 6 on the lifting portion 5, the lifting portion 5 is provided with a lifting hole 51, and the lifting hole 51 is made into a rectangular shape. Stacking platform 6 comprises a main frame, and main frame is provided with stacking platform 7, and bottom stacking platform 7 is fixedly connected...

Embodiment 2

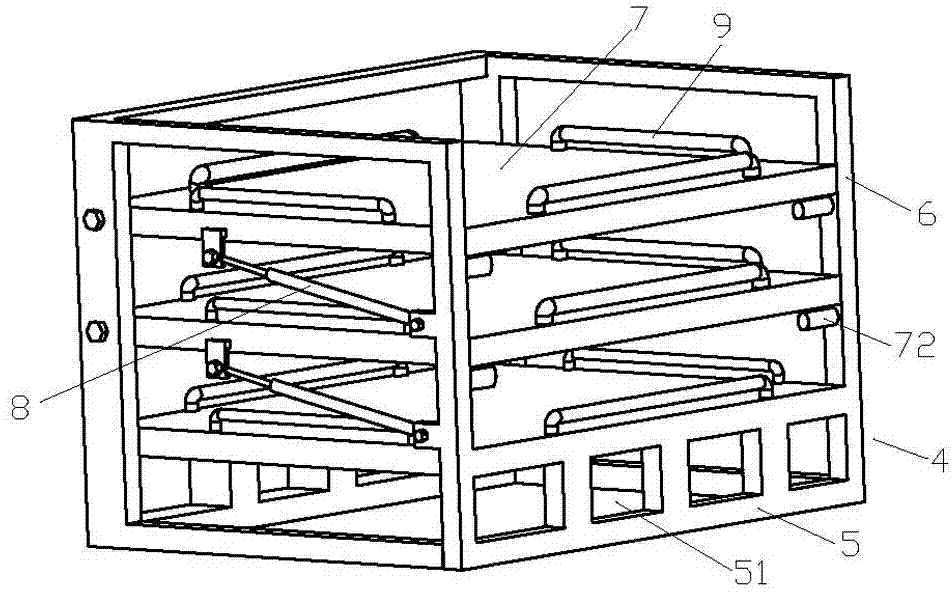

[0022] Example 2, such as image 3 As shown, the difference between it and Embodiment 1 is that the stacking platform 6 includes a main body frame, the main body frame is provided with a stacking platform 7, the bottom stacking platform 7 is fixedly connected to the main body frame, and one of the stacking platforms 7 on the upper floor The side is horizontally hinged on the main body frame and the main body frame on the opposite side of the hinged side is provided with a support rod 72, instead of using the support mode of the support foot 71.

Embodiment 3

[0023] Example 3, such as Figure 4 As shown, the difference from Embodiment 1 is that the stacking platform 7 includes a side frame 711 and a stacking board 712 placed on the side frame 711 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com