Integrated machine base module of shipborne anchor machine and mounting method of integrated machine base module

A technology of integrated windlass and windlass, which is applied to ships and other directions to achieve the effects of improving economic benefits, saving man-hours, and increasing the load capacity of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the present invention will be further described below with reference to the accompanying drawings.

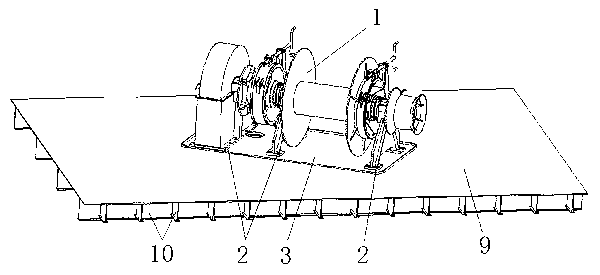

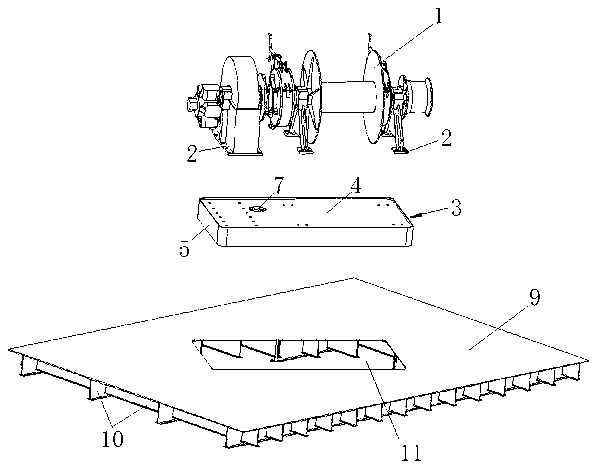

[0024] figure 1 , 2 , 3, and 4 show a structural diagram of an integrated machine base module of a marine windlass and its installation method.

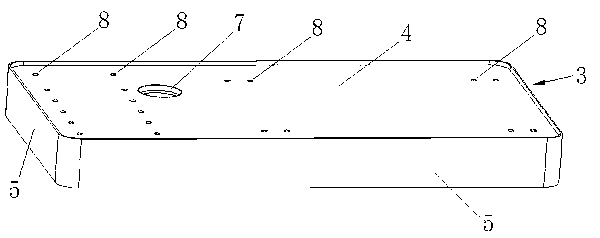

[0025] The integrated machine base module 3 of the marine windlass is composed of a rectangular panel 4, a coaming plate 5, a machine base stiffener 6, and a chain guide hole 7, etc. The rectangular panel 4 is a rectangular flat plate with rounded corners, and a chain guide hole 7 and several bolt holes 8 are opened on the rectangular panel 4; the area of the rectangular panel 4 must be able to arrange the windlass equipment; Corresponding to the direction of the anchor chain above, a cylindrical casing can be set to increase the strength of the chain guide hole. The bolt hole 8 should correspond to the windlass foot support 2. A circle of coaming 5 is welded around the rectangular panel 4, and the arcs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com