Repairing mortar for concrete floor

A technology for repairing mortar and concrete, applied in the field of building materials, can solve the problems of low bonding strength, poor workability, poor aesthetics, etc., and achieve the effects of reducing viscosity, improving workability, and increasing waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

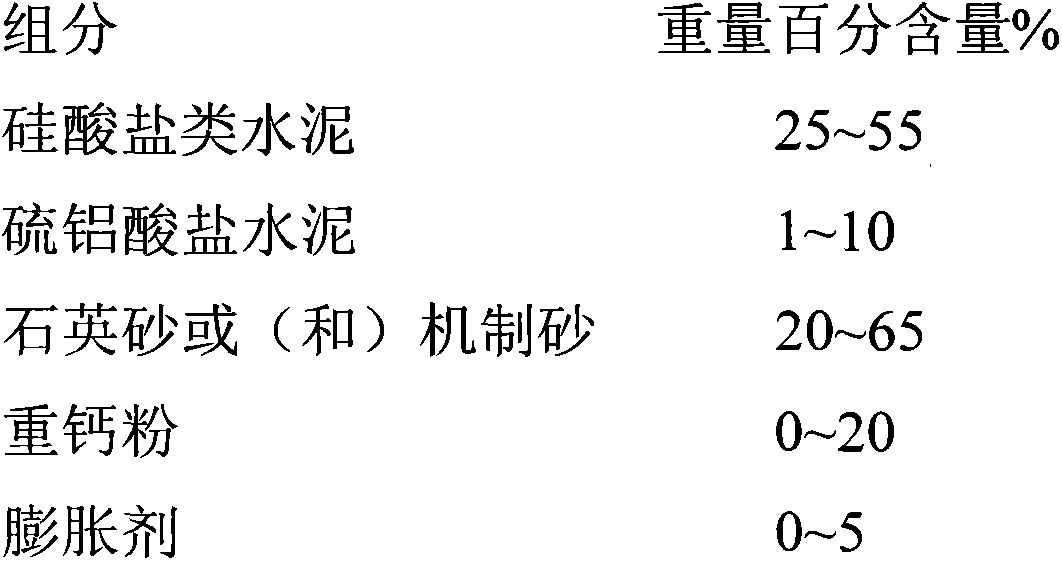

[0026] The utility model relates to a repair mortar for concrete ground, which can be used for thin-layer repair of concrete ground, and the thickness is less than 5mm. The specific formula is as follows:

[0027]

example 2

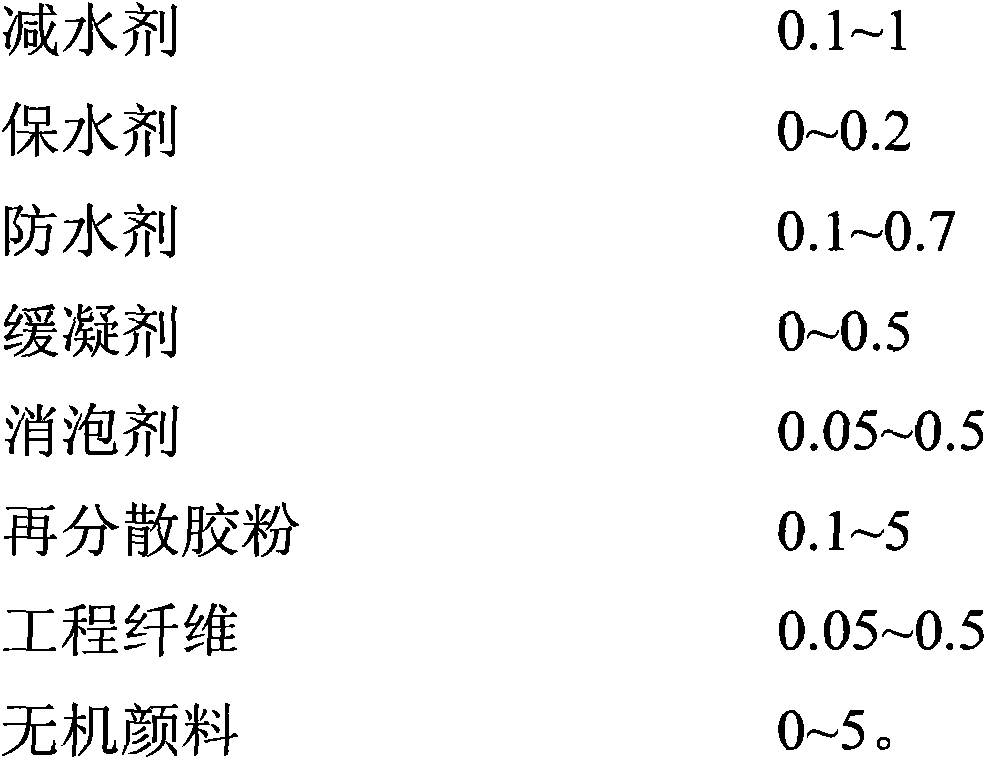

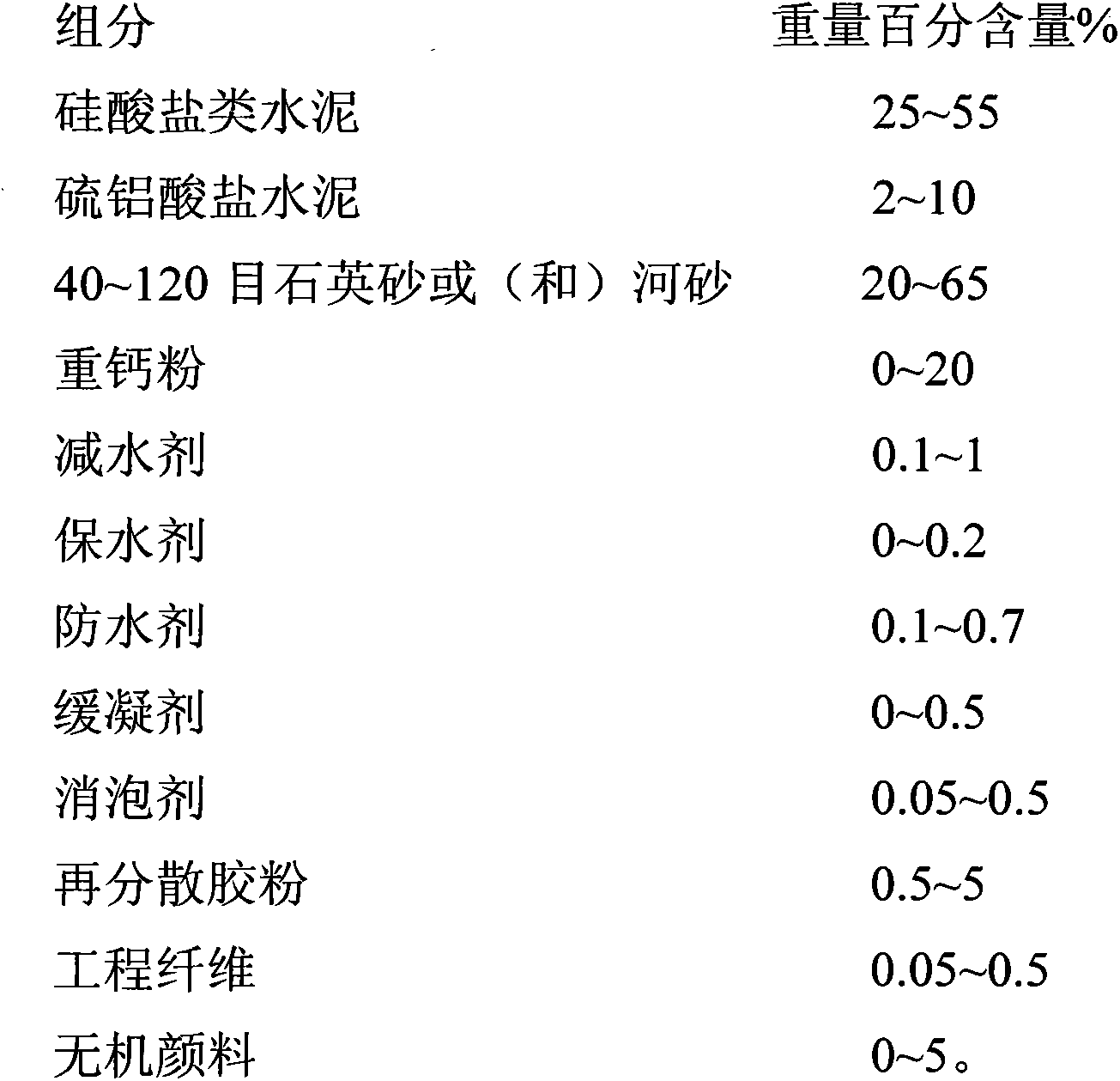

[0029] The utility model relates to a repairing mortar for concrete ground, which can be used for repairing potholes in the concrete ground, and the depth is greater than 5mm. The specific formula is as follows:

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com