Geotechnical engineering on-site detection method and device

An on-site detection and geotechnical engineering technology, which is applied in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as low detection efficiency, human theft, and system fragility, so as to facilitate the concealment of sensors and prevent omission of measurement points , to avoid the effect of missing measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

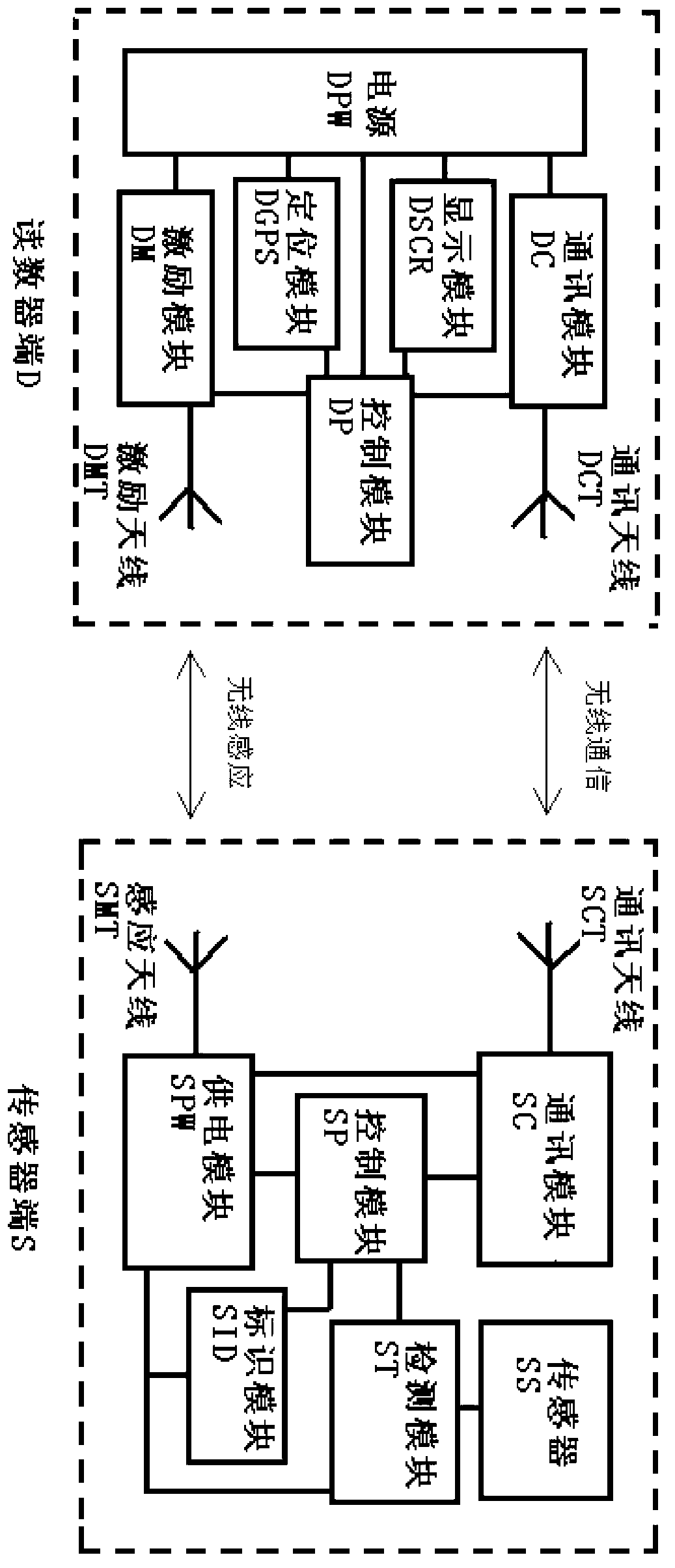

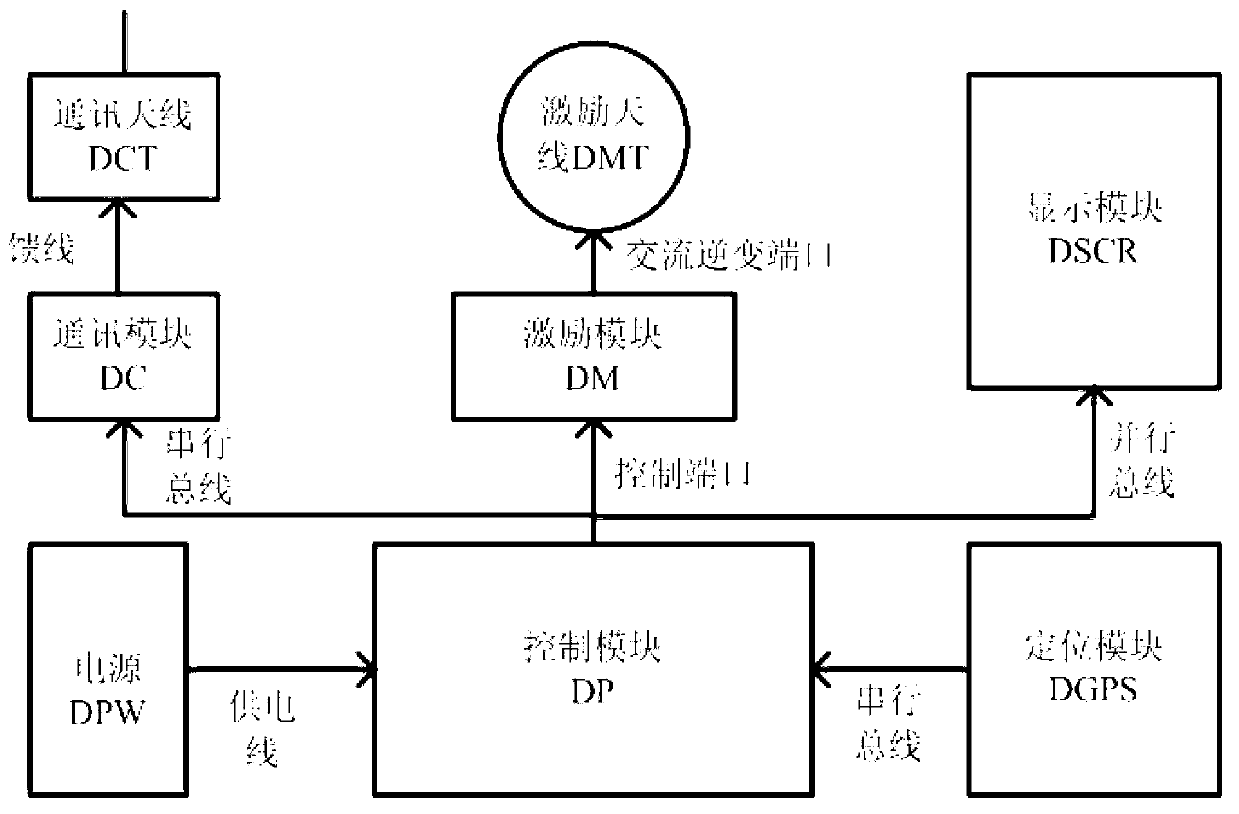

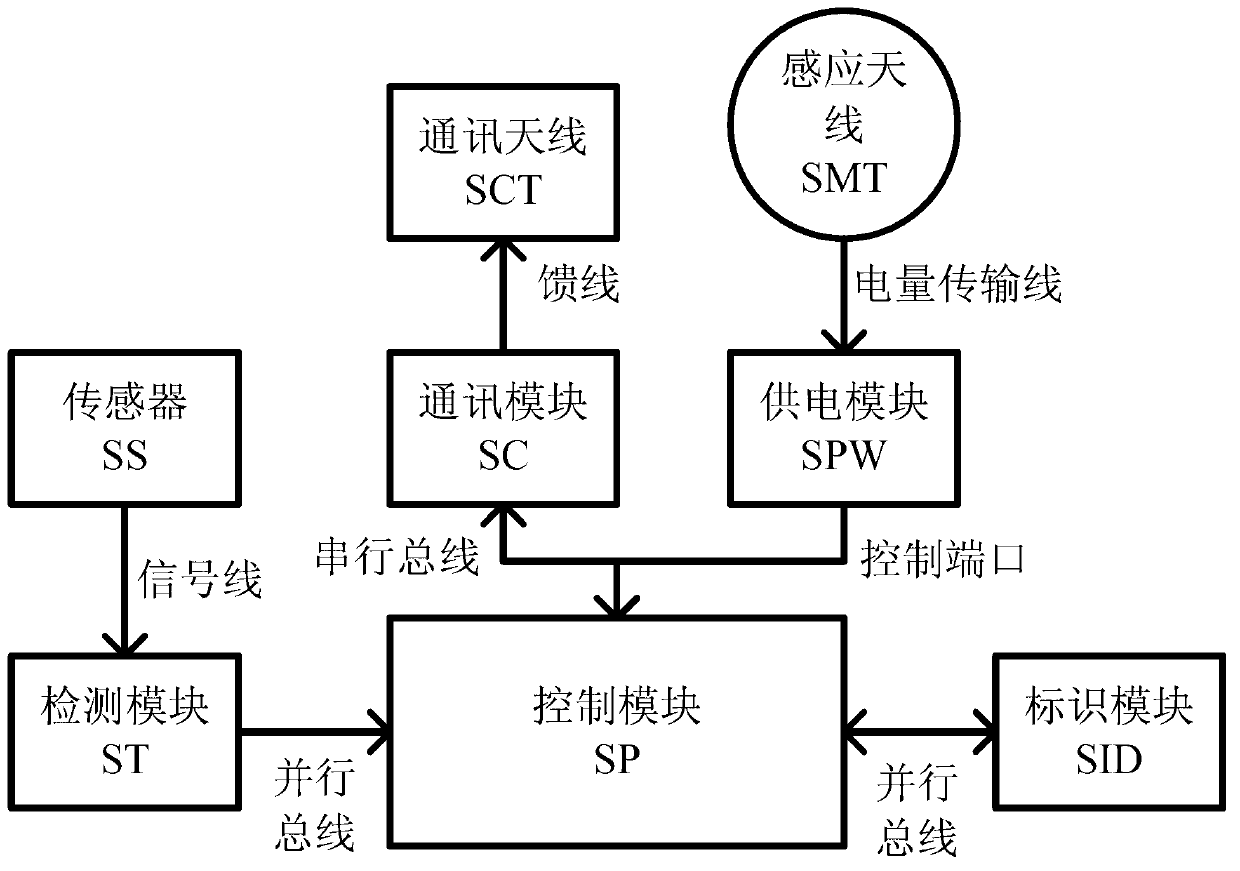

[0075] A geotechnical engineering site detection device ,This is a technical solution based on the sensor SS of the sensor terminal S as a strain gauge, the communication module DC of the reader terminal D and the communication module SC of the sensor terminal S based on 2.4G wireless transmission, and the supply mode of the sensor terminal S is based on the principle of resonance Directly rectified power supply. The structural block diagram of the reader terminal D is shown in Figure 2 (a), the circuit schematic diagram of the reader terminal D is shown in Figure 2 (b), the structural block diagram of the sensor terminal S is shown in Figure 3 (a), and the circuit schematic diagram of the sensor terminal S is shown in Fig. 3 (b1), the detection status process of the terminal D of the reader is shown in Figure 4 .

[0076] The device includes a reader terminal D and a sensor terminal S. The reader terminal D includes a power supply DPW, a control module DP, a display module...

Embodiment 2

[0124] A geotechnical engineering site detection device, which is an example of the sensor terminal S, is based on the sensor SS of the sensor terminal S as a vibrating wire displacement meter, and the communication module SC of the sensor terminal S is based on the technical scheme of 433M wireless transmission. The supply mode of S is to use a capacitive charge pump to realize power supply. The circuit schematic diagram of the sensor terminal S is shown in Figure 3 (b2), and the working process of the sensor terminal S is shown in Figure 5 (b).

[0125] The advantage of the charge pump technology is that it can accumulate charges in a relatively weak alternating electromagnetic field, so that the exciting antenna DMT at the reader end D can be farther away from the sensing antenna SMT at the sensor end S, for example, within 3 meters , to realize the power supply to the sensor terminal S. In a weak alternating electromagnetic field, the induced electromotive force induced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com