Oil-gas separator

A technology of oil-gas separator and separation tank, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc. It can solve the problems of poor oil drop separation effect and increased volume of oil-gas separator for separation effect, and achieve reduced oil content and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

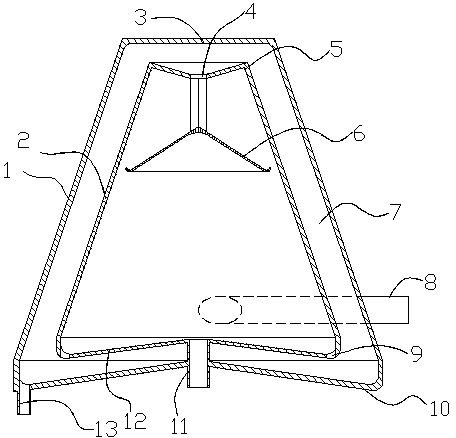

[0016] Describe an embodiment below in conjunction with accompanying drawing, the present invention is further described.

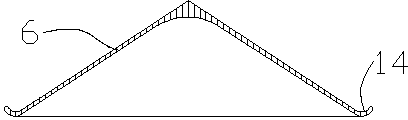

[0017] In the figure, a collision separation tank 2 is nested in the cyclone separation tank 1, and there is a gap between the cyclone separation tank 1 and the collision separation tank 2. The shape is frustum-shaped and the diameter of the bottom is larger than that of the top. The outline of the collision separation tank 2 is the same as that of the inner chamber 7 of the cyclone separation tank 1, and the diameter of the bottom is larger than that of the top. The bottom 10 of the cyclone separation tank is a conical surface, and the middle height is higher than the edge. An air inlet 8 is provided on the side of the bottom 10 of the cyclone separation tank, and the air inlet 8 communicates with the inner cavity 7 of the cyclone separation tank 1 . An air inlet 4 is arranged on the top surface of the collision separation tank, a conical oil separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com