Internal threaded connection brake valve

A technology of internal thread and gate valve, which is applied in the field of internal thread connection gate valve, can solve the problems of high cost and heavy weight, and achieve the effect of reducing the overall performance, reducing the use of materials, and the overall simplicity and elegance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

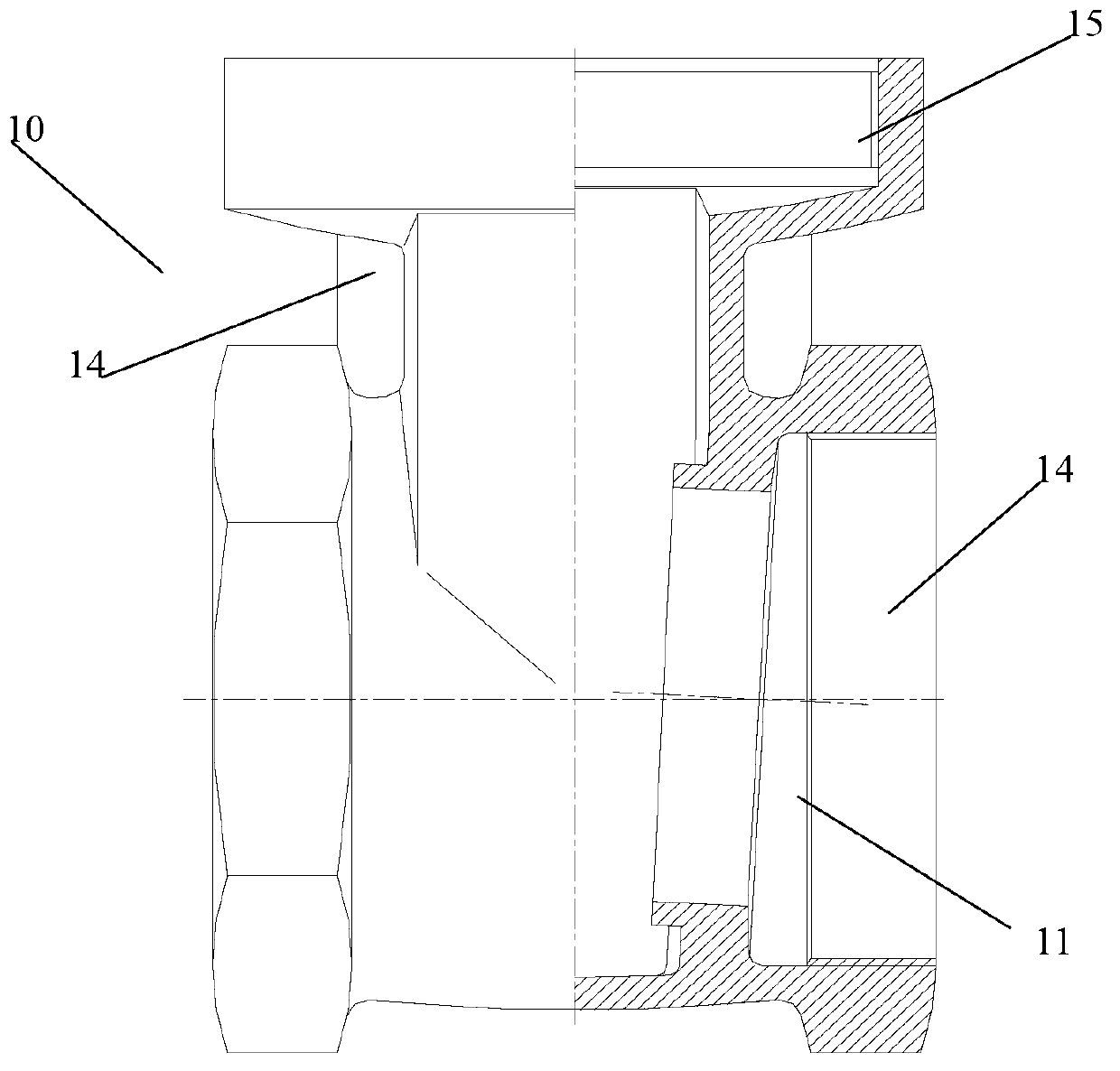

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

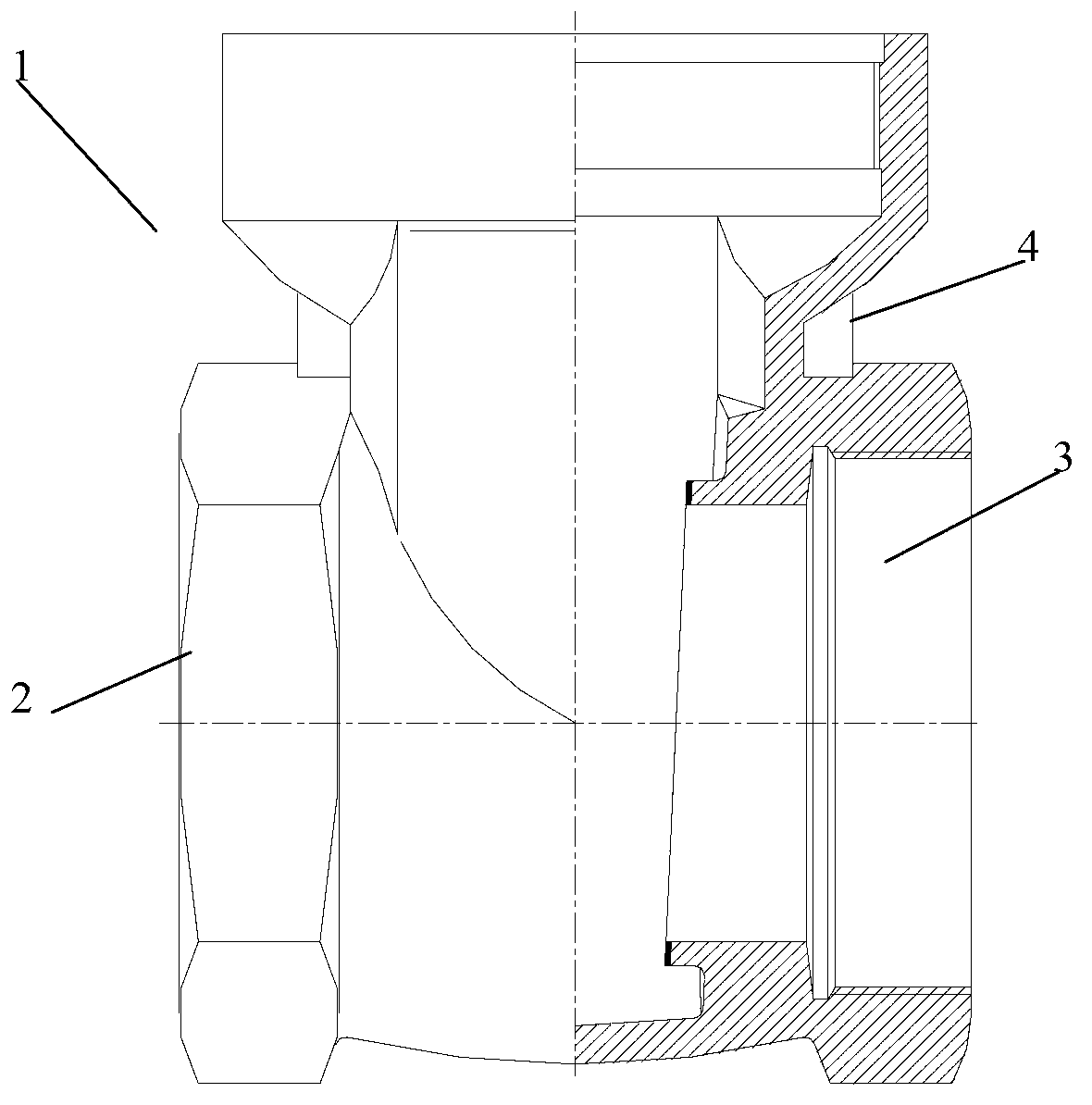

[0015] Such as figure 2 As shown, the gate valve of the present invention includes a three-way valve body 10 and a wedge gate (not shown in the figure), and the three-way valve body 10 includes water inlets 12 and water outlets 13 formed at both ends and formed at The upper part of the valve body is provided with the valve neck 14 of the gate operating port, the water inlet and the water outlet of the three-way valve body are respectively formed with internal threads, and the valve cavity of the three-way valve body is formed with The cross-section corresponding to the wedge-shaped gate is a V-shaped valve seat, that is, the three-way valve body and the gate opposite to each other are formed with an inclined surface, and two inclined surfaces are used to form a sealing surface corresponding to the wedge-shaped gate to realize wedge-shaped Seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com