SCR temperature regulating system of boiler and method for regulating smoke temperature of SCR inlet of boiler

A temperature regulation system and boiler technology, which is applied to the boiler's SCR temperature regulation system to adjust the boiler SCR inlet flue gas temperature, can solve the problems of not meeting environmental protection requirements, easy adhesion, and large investment costs for heating surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

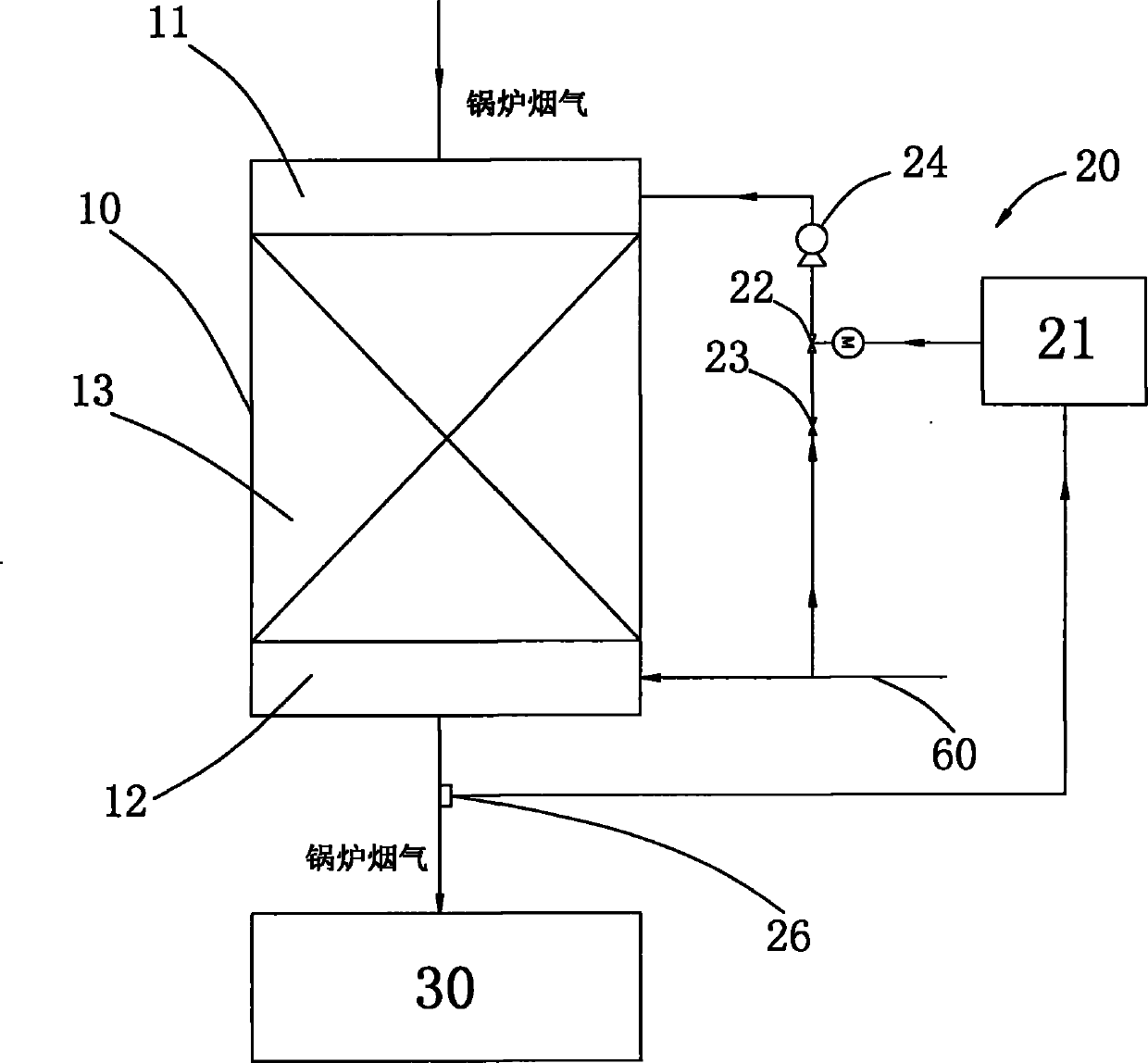

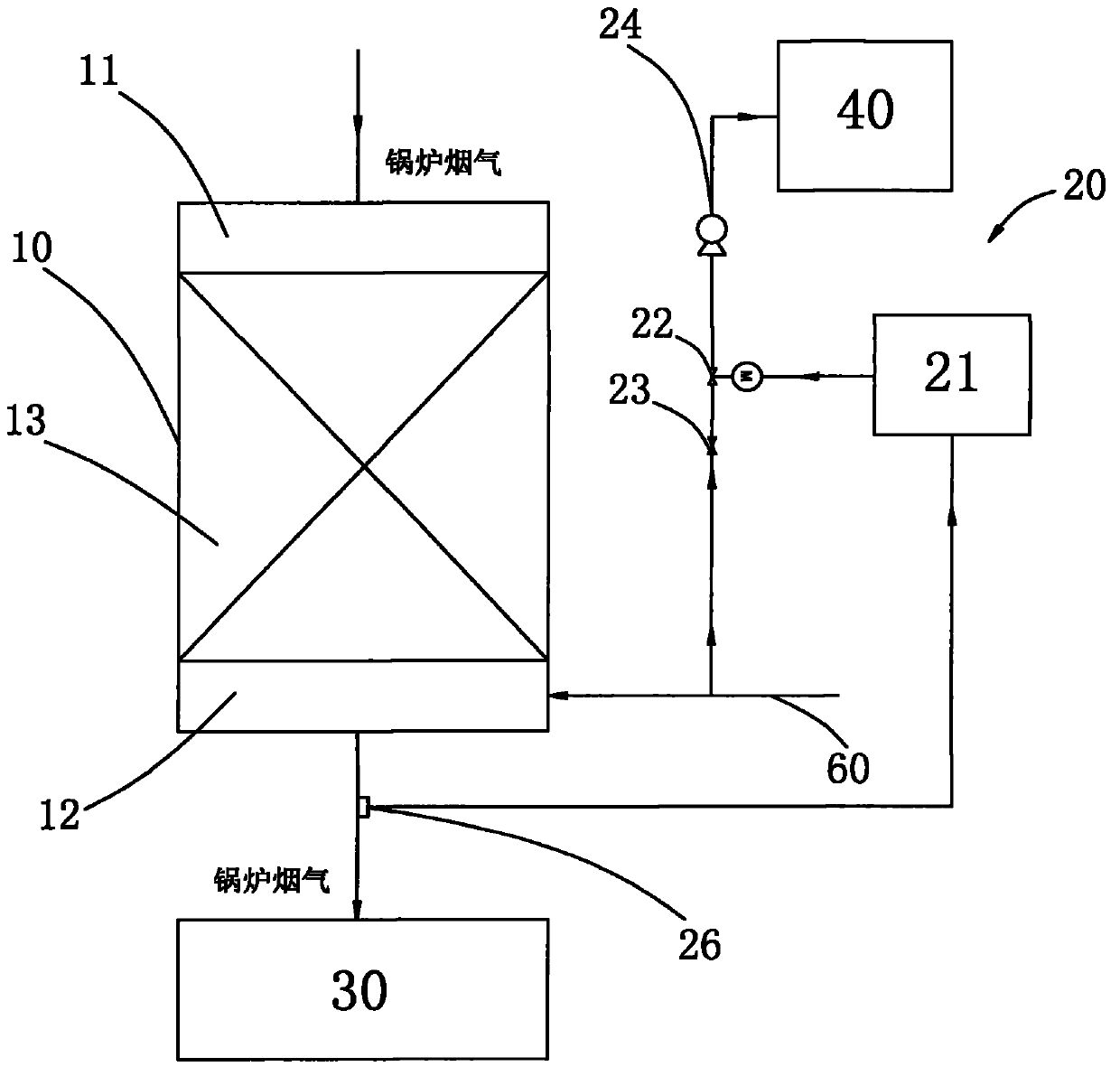

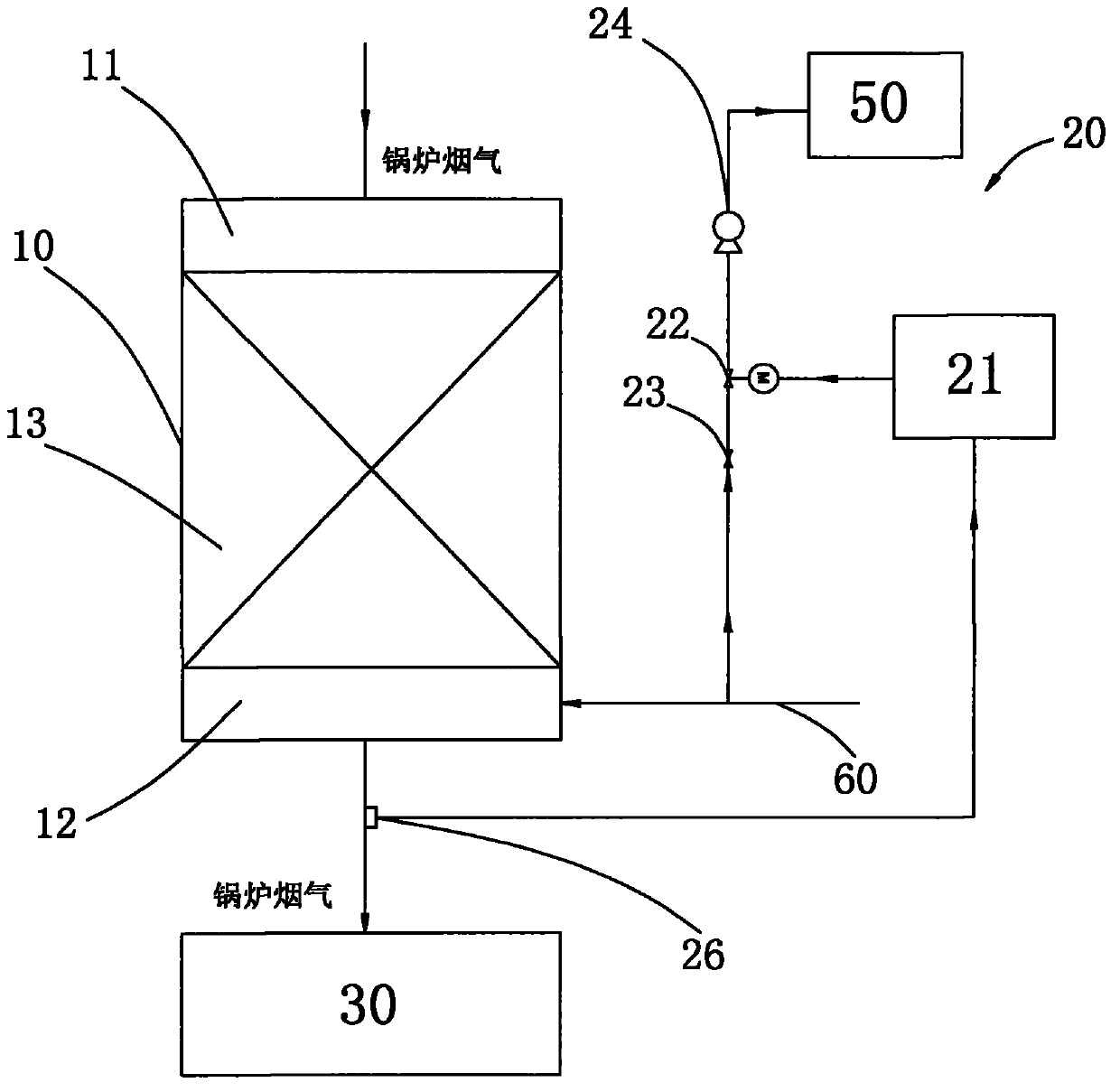

[0022] The invention discloses a boiler system and a method for adjusting the smoke temperature at the SCR inlet of the boiler. The SCR temperature regulation system of the boiler includes an economizer, and the economizer includes an outlet header of the economizer communicated with the boiler, and an inlet header of the economizer communicated with the economizer; the inlet header of the economizer is connected to There is a boiler water supply pipe, and the boiler water supply pipe or the inlet header of the economizer is connected with a temperature regulating device for adjusting the flow rate of heat-absorbing working fluid in the boiler water supply pipe.

[0023] The method for adjusting the flue gas temperature at the boiler SCR inlet of the boiler system of the present invention comprises the steps of: monitoring the flue gas temperature before the inlet of the SCR device, and when the flue gas temperature is set at a preset value, reducing the number of boiler feedwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com