Method for measuring orientation differences of orientation silicon steel crystal particles

A grain-oriented, oriented silicon steel technology, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as increased measurement deviation, sample deviation from rolling direction, and selected area is not large enough to achieve The effect of avoiding errors, simple operation and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Choose high magnetic induction oriented silicon steel sheets with different magnetic induction intensities, the size is 300mm×30mm×0.3mm, the magnetic induction B 8 They are 1.914T, 1.892T, 1.845T, 1.773T respectively, and the numbers are 1#, 2#, 3#, 4#.

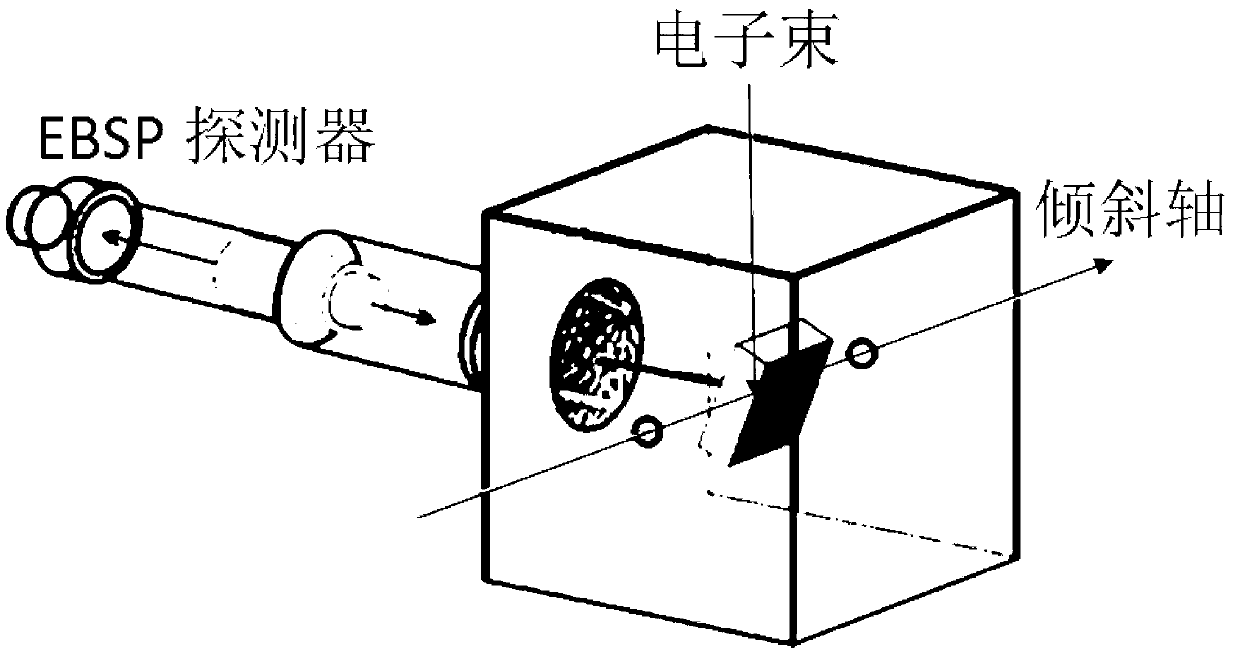

[0034] The scanning electron microscope used in this experiment is a Zeiss ZEISS SUPRA55VP scanning electron microscope equipped with an EDAX OIM electron backscatter diffraction (EBSD) system.

[0035]According to the method of the present invention, at first take the small piece sample of 100mm * 10mm * 0.3mm in the central part of every silicon steel sheet, successively use 200# sandpaper, 600# sandpaper, 800# sandpaper, 1000# sandpaper, 1200#, 1500# Grinding with sandpaper, and then electropolishing to be suitable for EBSD detection. Scan each grain in the selected area of the test sample to obtain the Euler angle of each grain, calculate the orientation difference between adjacent grains and between grains and...

Embodiment 2

[0040] Select ordinary oriented silicon steel sheets with different magnetic induction intensities, the size is 300mm×30mm×0.27mm, the magnetic induction B 8 They are 1.905T, 1.883T, 1.877T, 1.792T respectively, and the numbers are 5#, 6#, 7#, 8#.

[0041] The test sample preparation and detection method are the same as in Example 1, and the finally obtained data are shown in Table 2.

[0042] It can be seen from Table 2 that for the ordinary grain-oriented silicon steel sheet in this embodiment, as the magnetic induction intensity B 8 The decrease of the average misorientation Ψ increases.

[0043] Table 2 Test results of misorientation between grains, misorientation between grains and standard Gaussian texture, and average misorientation

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com