Installing method of sensor for detecting XLPE (cross linked polyethylene) power cable partial discharge

A technology for power cables and installation methods, applied in the direction of testing dielectric strength, etc., can solve the problems of high use cost and poor versatility, and achieve low manufacturing and use costs, enhanced versatility, and avoid corona or suspension discharge phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

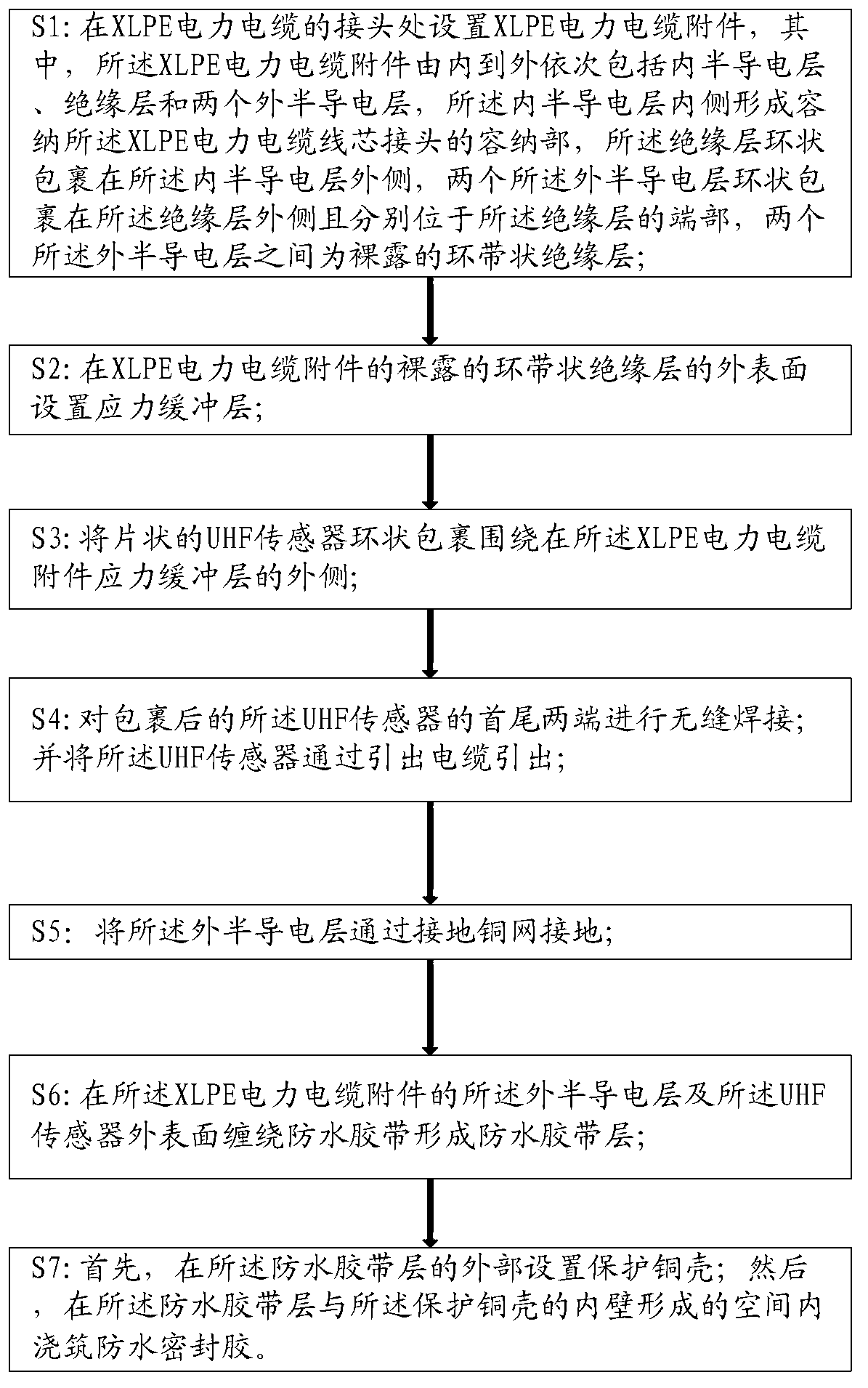

[0027] As an embodiment of the present invention, the described sensor installation method for partial discharge detection of XLPE power cables, such as figure 1 shown, including the following steps:

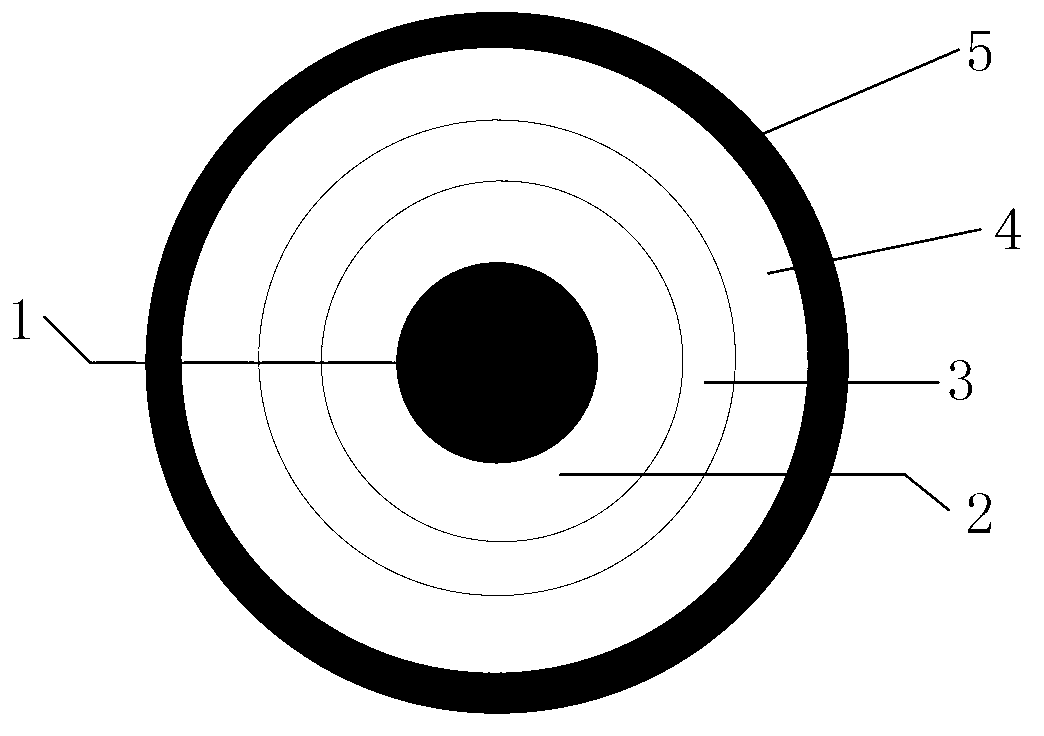

[0028] S1: Set the XLPE power cable accessories at the joint of the XLPE power cable, such as figure 2 As shown, wherein, the XLPE power cable accessory includes an inner semiconductive layer 2, an insulating layer 3 and two outer semiconductive layers from the inside to the outside, and the inner semiconductive layer 2 is formed to accommodate the XLPE power cable The accommodating part of the core joint 1, the insulating layer 3 is annularly wrapped outside the inner semiconductive layer 2, and the two outer semiconductive layers are annularly wrapped outside the insulating layer 3 and are respectively located on the insulating layer 3 at both ends, and between the two outer semiconducting layers is an exposed ring-shaped insulating layer 3 . Wherein, the XLPE power cable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com