Method for repairing crystalline silicon solar cell with leaky edges

A technology of solar cells and edge leakage, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of four main grids that cannot be calibrated, and achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

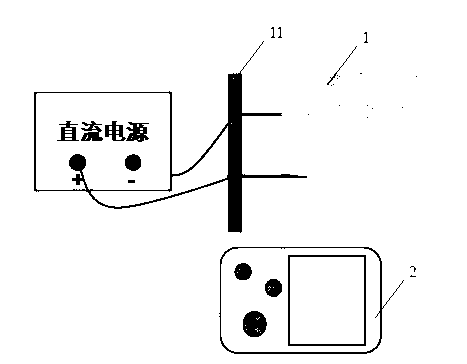

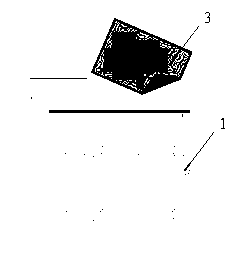

[0020] see figure 1 and figure 2 As shown, first, vertically fix the edge leakage cell on a bracket 11 and connect it to a DC power supply. Since the leakage area of the battery sheet 1 will heat up after being connected to the DC power supply, the specific location of the leakage can be easily confirmed by using a thermal imager 2. Then manually use sandpaper 3 to grind the edge of the cell leakage and re-test. If the leakage and efficiency of the cell reach the normal value, the grinding is successful, and the cell can be produced normally. If the leakage and efficiency do not reach the normal value, continue grinding. until it reaches the normal value.

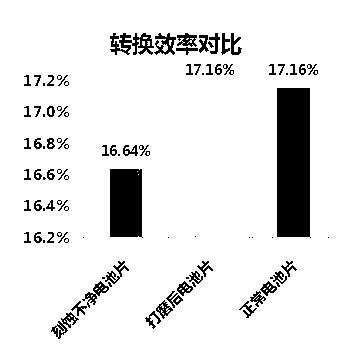

[0021] see image 3 and Figure 4 As shown, the leakage and conversion efficiency of the edge leakage cells with dirty or unetched edges reached the level of normal cells after being sanded, and the appearance also met the control standards of normal cells.

[0022] The method for repairing the edge leakage of crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com