Two magnetoelectric composite materials and preparation method thereof

A technology of magnetoelectric composite materials and magnetostrictive materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, device components, etc. and other problems, to achieve the effect of strong promotion and application value, simple structure, and high magnetic and electrical properties

Inactive Publication Date: 2013-09-04

SHAANXI NORMAL UNIV

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention provides two kinds of magnetoelectric composite materials and their preparation methods, aiming to solve the problem that the magnetoelectric composite materials provided by the prior art cannot obtain high magnetoelectric properties at room temperature, the sample preparation is complicated, and it is not suitable for large-scale production , which is not conducive to the application of practical devices in the problem of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

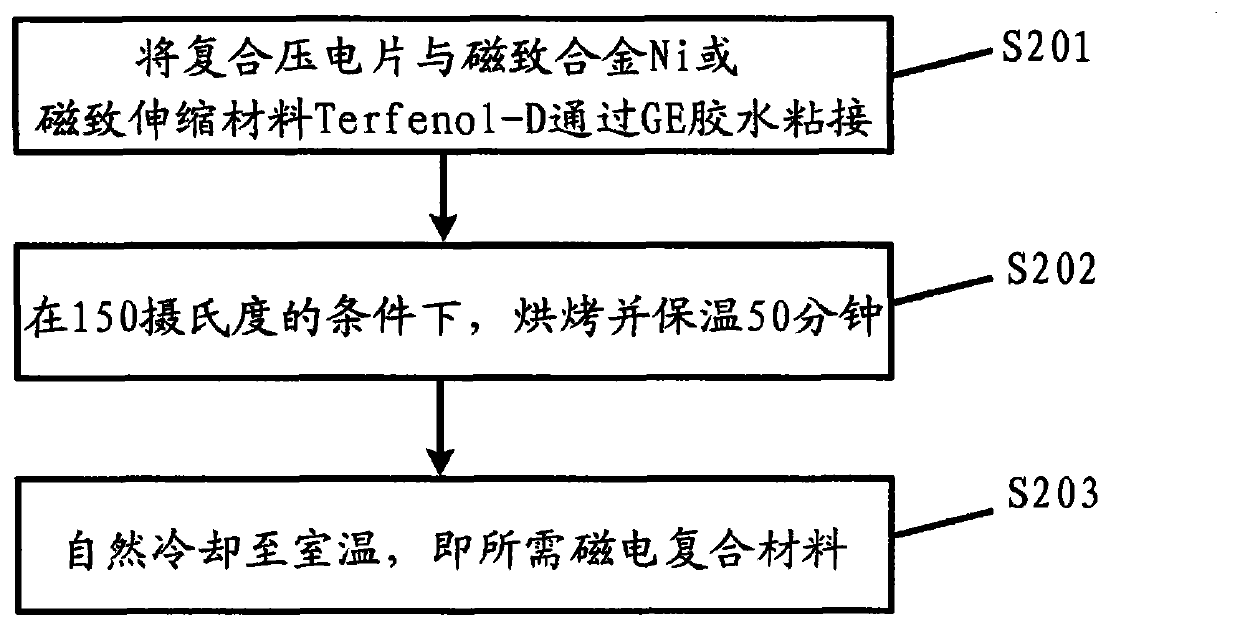

[0031] The preparation method comprises the following steps:

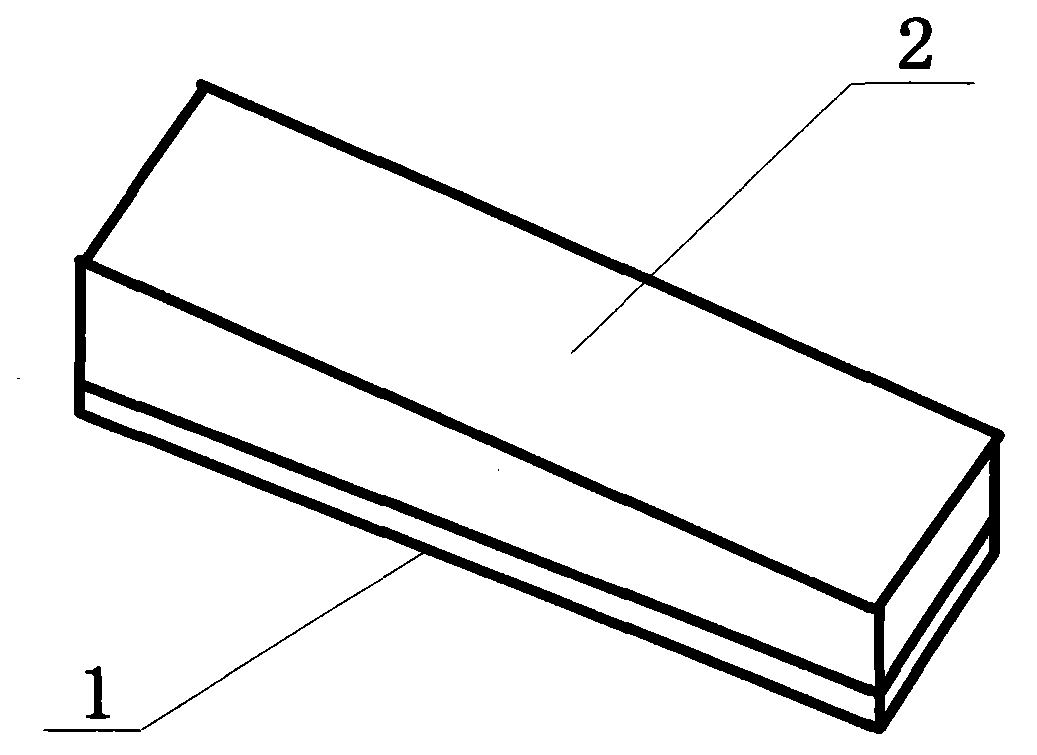

[0032] Step S201, bonding the composite piezoelectric sheet 1 to the magnetostrictive alloy Ni or the magnetostrictive material Terfenol-D2 through GE glue;

[0033] Step S202, under the condition of 150 degrees Celsius, bake and keep warm for 50 minutes;

[0034] Step S203, naturally cooling to room temperature, that is, the required magnetoelectric composite material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

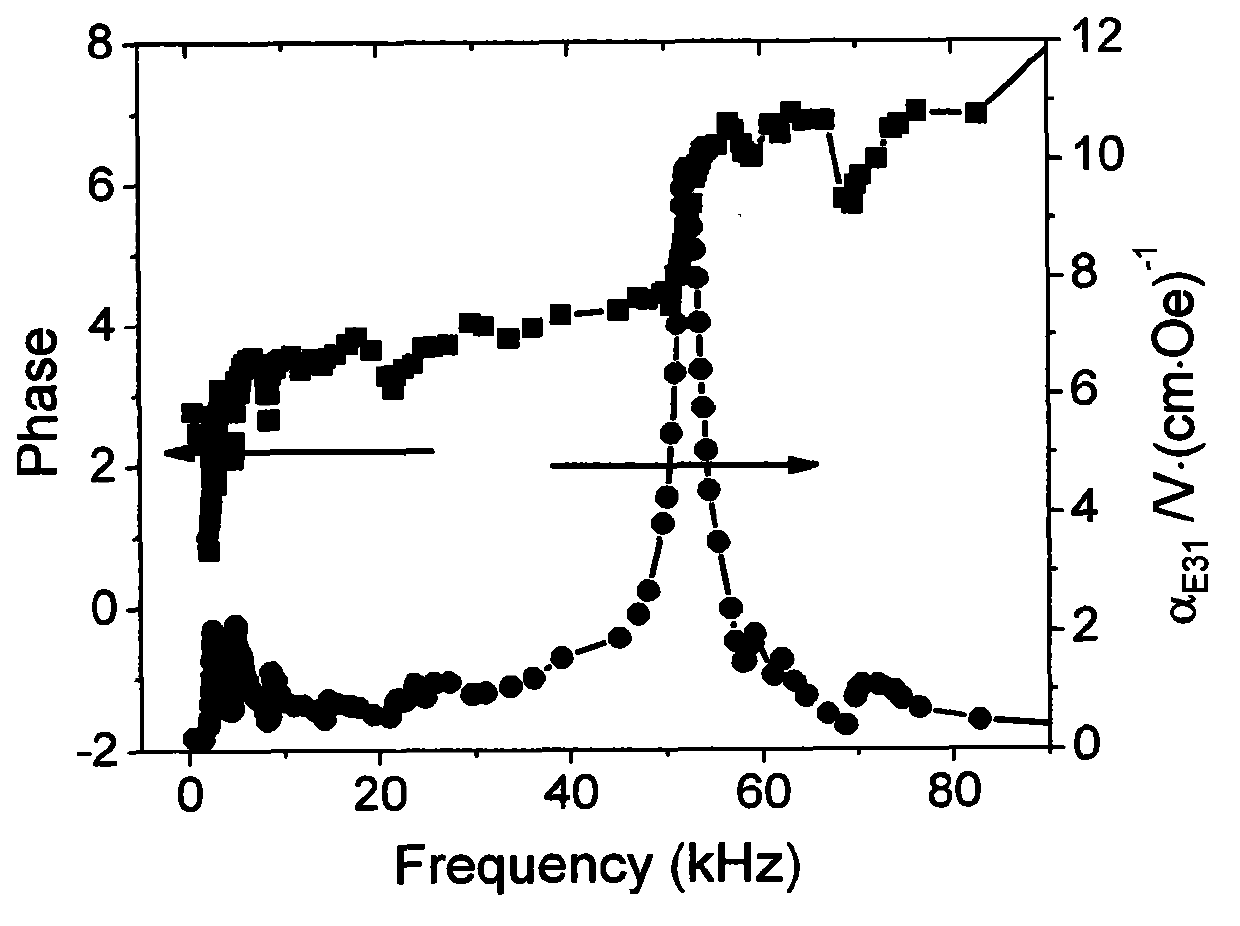

The invention discloses two magnetoelectric composite materials and a preparation method thereof. The magnetoelectric composite material consists of a composite piezoelectric piece and a magnetostrictive alloy Ni or magnetostrictive material Terfenol-D, wherein the composite piezoelectric piece is fixedly adhered to the magnetostrictive alloy Ni or magnetostrictive material Terfenol-D through GE glue, and the composite piezoelectric piece is made by connecting a plurality of layers of composite piezoelectric pieces in parallel; and the composite piezoelectric piece has great capacitance, and the magnetoelectric composite material has high magnetoelectric conversion sensitivity. The preparation method comprises the following steps of: firstly, adhering the composite piezoelectric piece and the magnetostrictive alloy Ni or magnetostrictive material Terfenol-D through GE glue; secondly, baking and holding for 50 min at a temperature of 150 DEG C; and finally, naturally cooling to room temperature to obtain the required magnetoelectric composite material. The magnetoelectric composite materials have very high magnetoelectric sensitivity and inverse magnetoelectric effects at normal temperature, and the sample preparation is simple, so that the materials can be mass-produced; the compounding of the composite piezoelectric piece and the magnetostrictive alloy Ni requires a low bias ratio, so that the materials are favorable for application in practical devices; and the structure is simple, and the practicality is strong, so that the materials have stronger popularization and application values.

Description

technical field [0001] The invention belongs to the technical field of magnetoelectric materials, and in particular relates to two magnetoelectric composite materials and a preparation method thereof. Background technique [0002] The magnetoelectric effect refers to the phenomenon that the material undergoes an electric polarization response in an external magnetic field, or the phenomenon that the material undergoes a magnetization change in an external electric field. The latter is usually called the inverse magnetoelectric effect. Since the French physicist Curie P predicted the magnetoelectric effect at the end of the 19th century, many single-phase magnetoelectric materials have been discovered, such as Cr 2 o 3 , YMnO 3 Wait. The ferromagnetic Curie temperature point (antiferromagnetic Neel temperature point) of single-phase magnetoelectric materials is generally far below room temperature, and their magnetoelectric coupling is very weak, so they have not yet been ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L41/02H01L41/25H10N30/03

Inventor 周剑平张赛欢施展刘鹏陈晓明

Owner SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com