High-voltage resistant connector

A connector and voltage technology, applied in the direction of connection, components and circuits of connecting devices, can solve the problems of inability to realize high-voltage signal transmission, inability to large-scale application, and different use environments, and achieve good mechanical and mechanical environmental performance. Spatial adaptation, the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

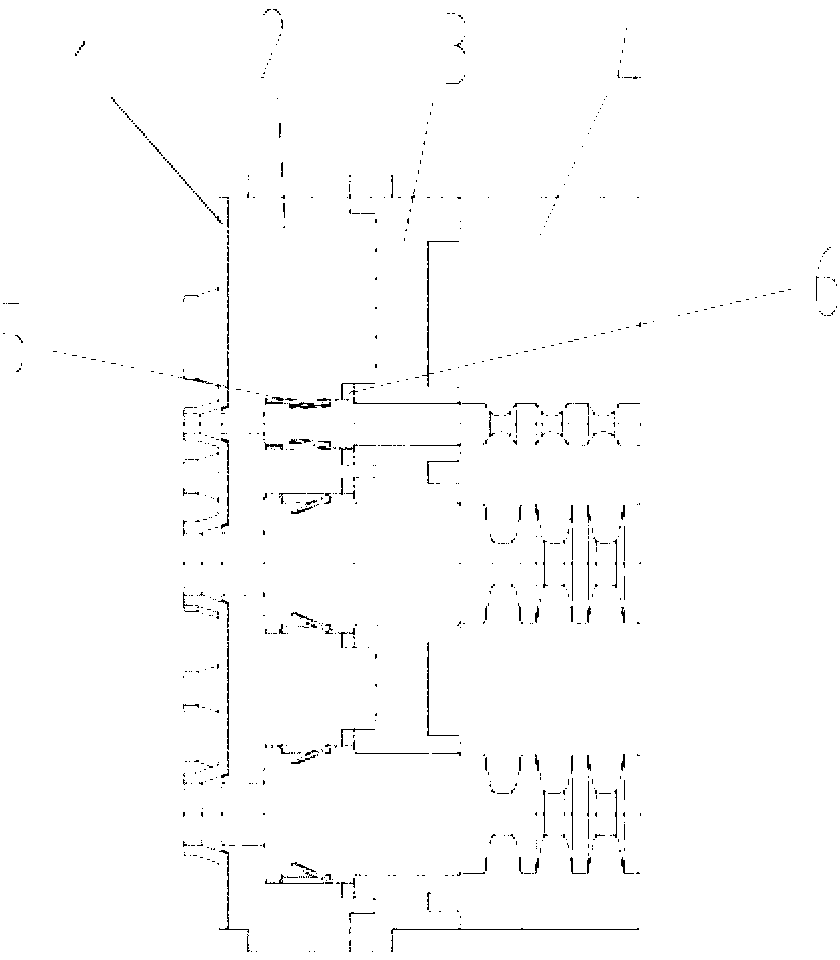

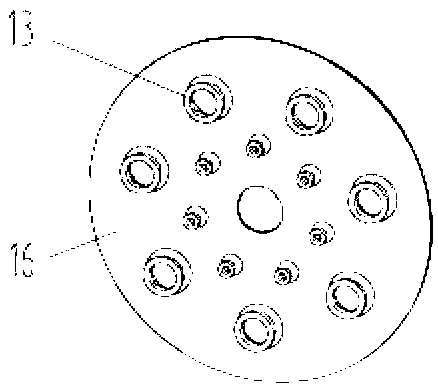

[0030] Such as figure 1 , figure 2 As shown, the high voltage resistant connector of the present invention is composed of a plug and a socket. The plug is composed of a plug housing and an internal insulation component of the plug located in the plug housing. The internal insulation component of the plug is composed of an interface gasket 1, a plug insulator 2 , plug cover plate 3, plug sealing body 4, plug positioning claw 5, and plug rubber ring 6; The joint surface 17 is matched; the plug positioning claw 5 is put into the plug insulator 2, and then put into the plug rubber ring 6, and the plug insulator 2 is bonded and fixed by the plug cover plate 3 sealant; the plug cover plate 3 and the plug sealing body 4 The space is bonded by sealant; the socket consists of a socket shell and an internal insulation component of the socket located in the socket shell, and the internal insulation component of the socket consists of a socket insulator 9, a socket cover plate 7, a sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com