Papermaking and products made thereby with ionic crosslinked polymeric microparticle

A polymer, ionic technology, applied in the priority of U.S. Provisional Patent Application 61/408,262, papermaking and papermaking products, in the field of papermaking, can solve problems such as conflicts, and achieve the effect of improving papermaking retention efficiency and dewatering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

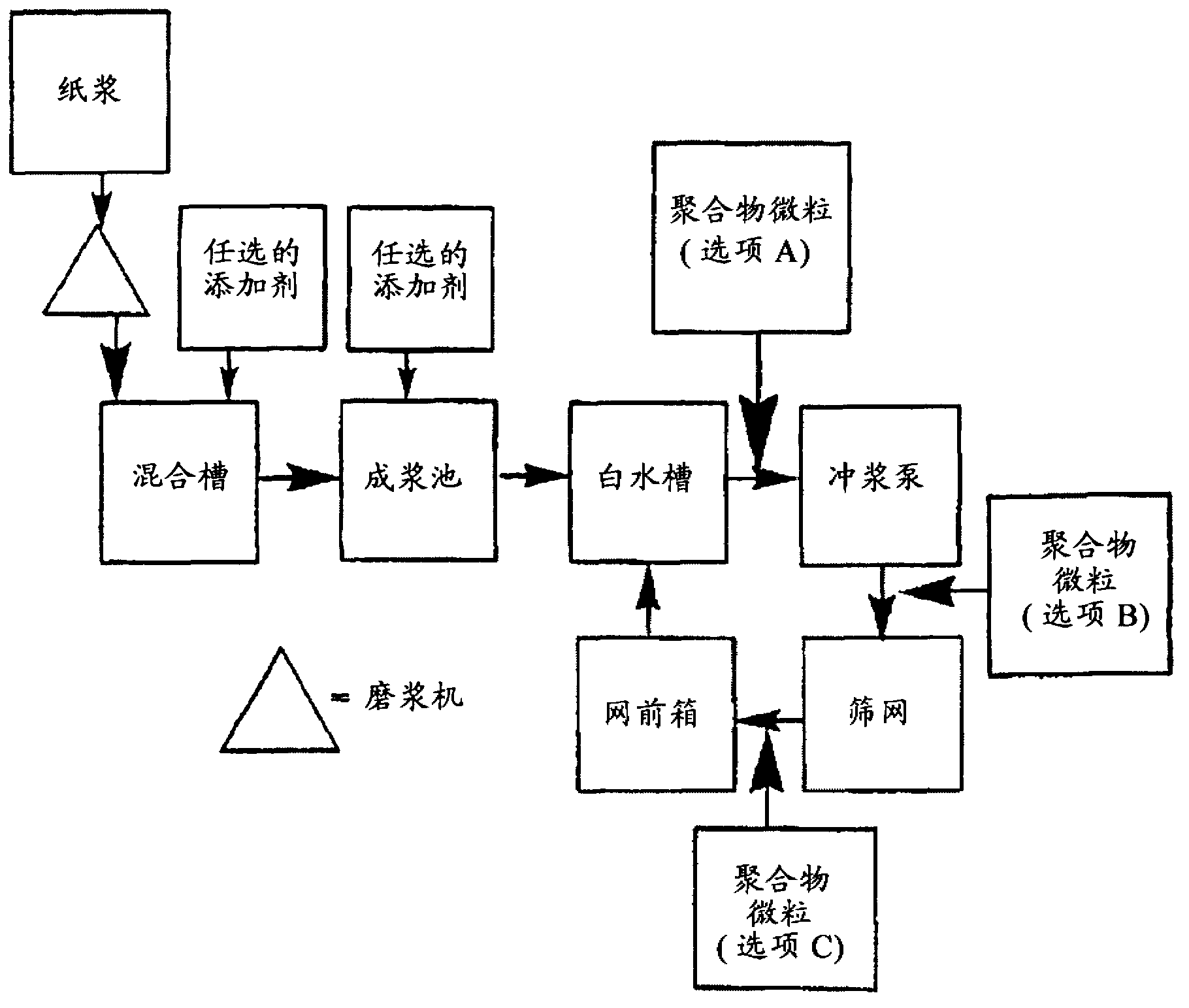

Method used

Image

Examples

Embodiment 1

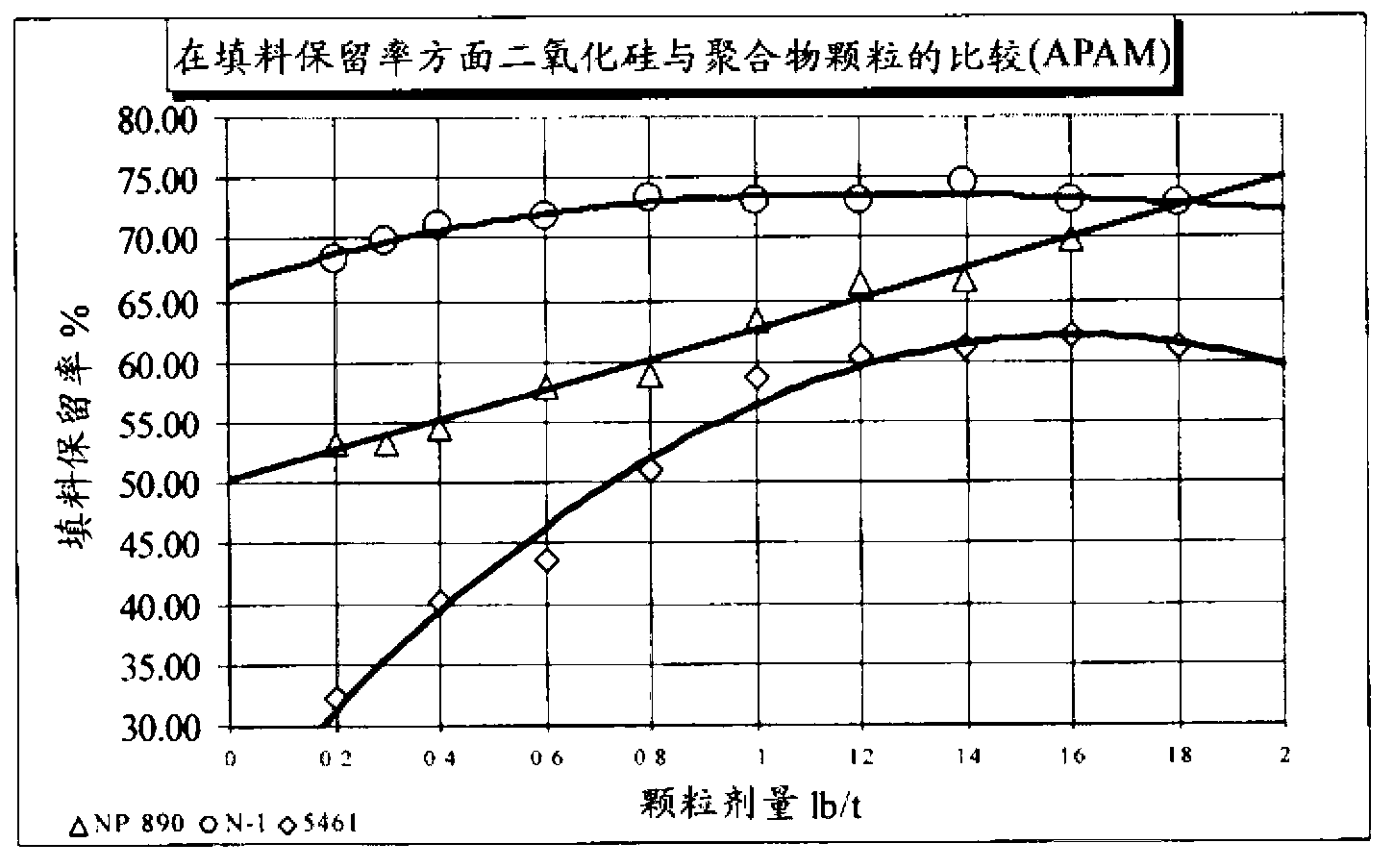

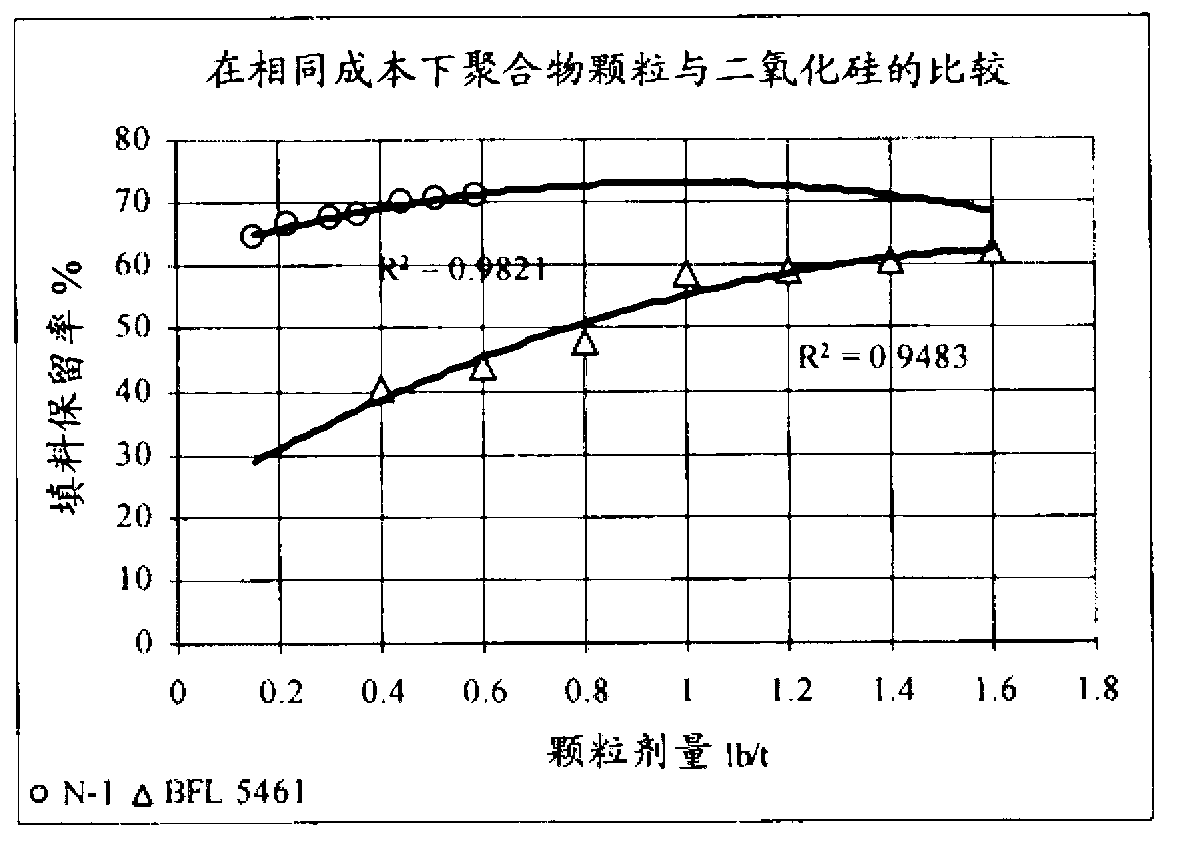

[0103] Pulp Suspension Filler Retention and Dewatering Test

[0104] In this test, the effect of different microparticles with or without ionically crosslinked acrylic-acrylate copolymer microparticles on suspension fiber retention and dewatering rate of bleached kraft pulp was investigated. Pulp stock (70% hardwood, 30% softwood) (CSF450) was prepared from commercial pulpboard obtained from a commercial paper mill in the United States. The pulp board is a standard craft product. For the pulp, bleached southern pine kraft pulp boards (softwood pulp boards) and bleached southern mixed hardwood pulp boards were used for testing. For refining, softwood and hardwood pulp sheets were individually torn into small pieces and soaked in water overnight. Each pulp was refined in a beater. Apply TAPPI standard method for pulp refining (T200om-89). The pulp was refined to a desired Canadian standard freeness (CSF) of 450. Refined softwood and hardwood pulps were mixed in a ratio of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| flow consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com