Patents

Literature

69 results about "Acrylyl-CoA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition and method for whitening teeth

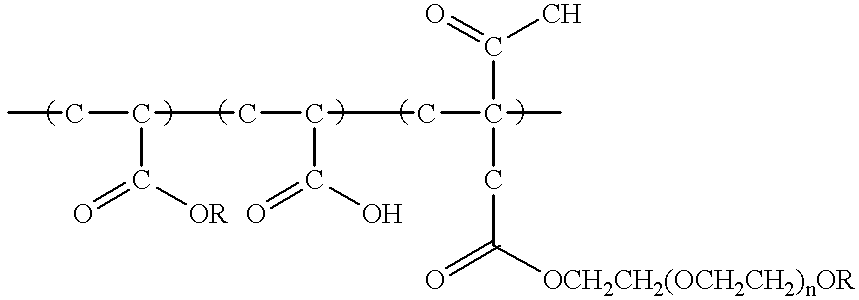

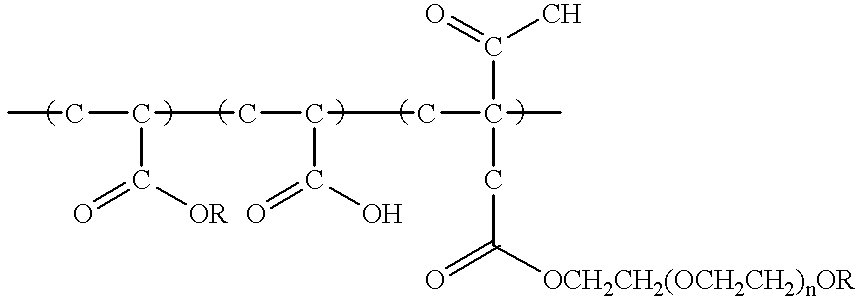

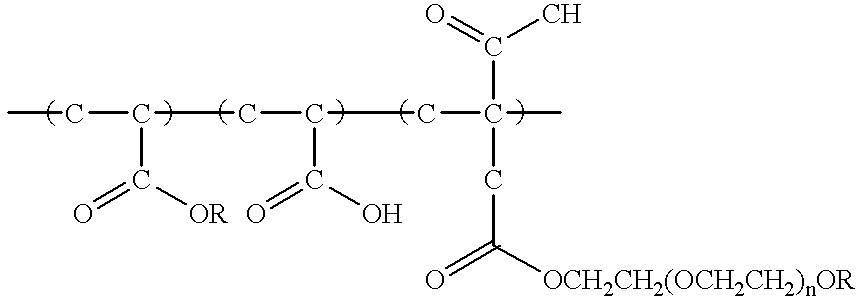

A method for whitening teeth that includes contacting at least one tooth with a composition that includes a bleaching agent; a carrier; and an acrylate / alpha, beta-ethylenically unsaturated dicarboxylic acid or anhydride copolymer such as an acrylate itaconate copolymer. The acrylate itaconate copolymer may be an alkali-swellable polymer and the composition may further include an alkaline additive.

Owner:MCLAUGHLIN GERALD

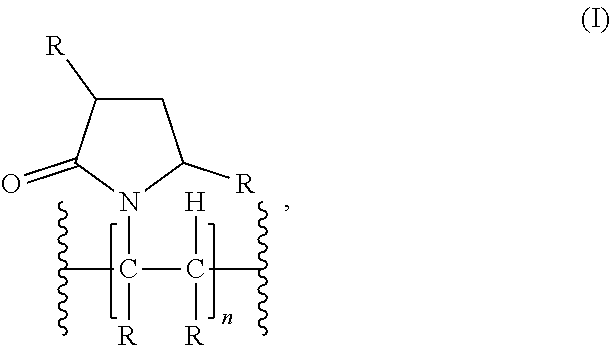

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

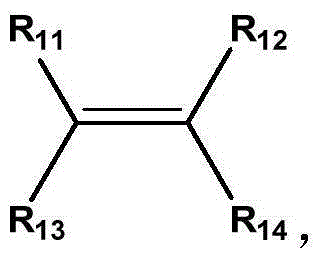

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

Composition and method for whitening teeth

A method for whitening teeth that includes contacting at least one tooth with a composition that includes a bleaching agent; a carrier; and an acrylate / alpha,beta-ethylenically unsaturated dicarboxylic acid or anhydride copolymer such as an acrylate itaconate copolymer. The acrylate itaconate copolymer may be an alkali-swellable polymer and the composition may further include an alkaline additive.

Owner:MCLAUGHLIN GERALD

Cleaning compositions

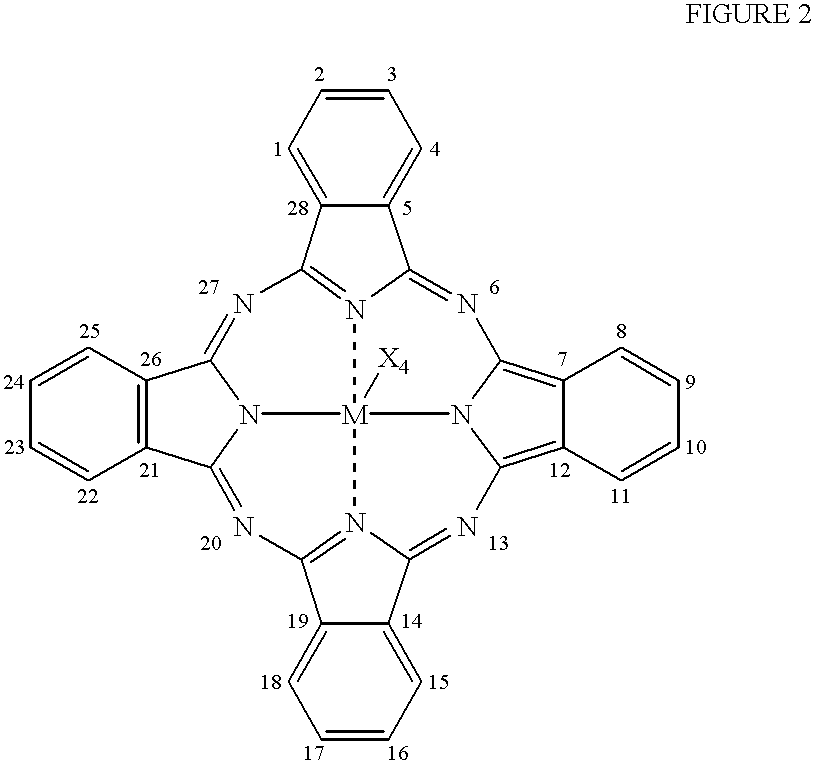

InactiveUS6339055B1Organic detergent compounding agentsAnionic surface-active compoundsMethacrylatePorphyrin

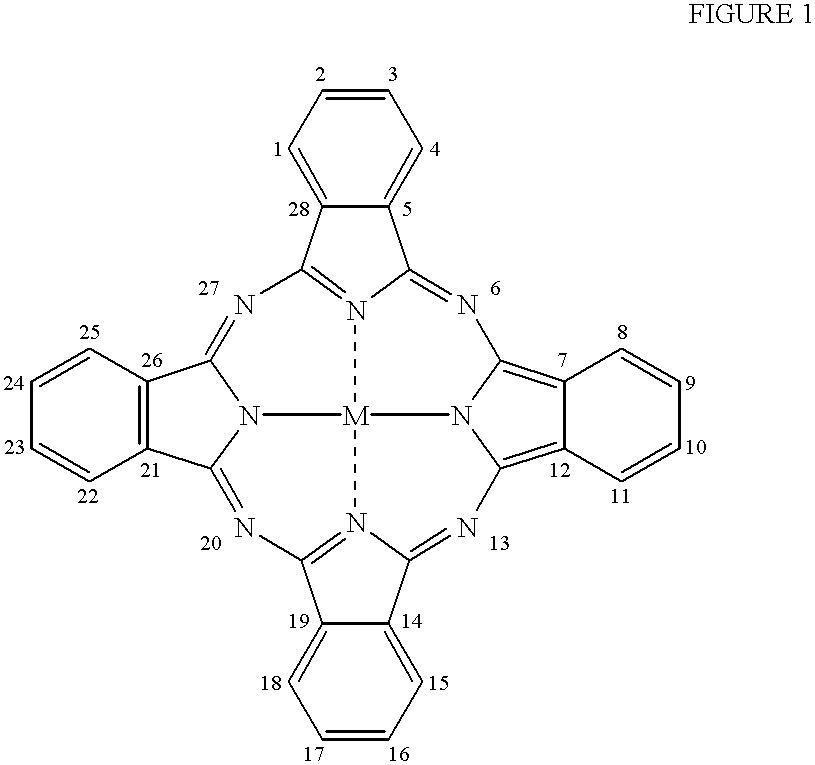

The present invention relates to a photo bleaching compositions comprising:A) from 0.5 ppm by weight, of a photo bleaching agent, said agent comprising:a) a polymeric component, said polymeric component comprising one or more polymeric compounds having an average molecular weight of from 500 to 1,000,000 wherein at least 50% of the monomers which comprise said polymeric compounds comprise one or more di-polar, aprotic groups and have a polymerizable vinyl moiety, the balance comprising monomers selected from the group consisting of acrylic acid, acrylic acid esters, acrylic acid amides, methacrylic acid, methacrylic acid esters, methacrylic acid amides, and mixtures thereof; andb) a photo bleaching component, said photobleaching component comprising a porphyrin or a phthalocyanine ring wherein said phthalocyanine ring can optionally be substituted at one or more ring positions, and said ring comprising a transition metal or cation having an oxidation state of two or greater;wherein said photo bleaching component is integrated with said polymeric component to form said photo bleaching agent and the weight ratio of polymeric component (a) to photobleaching component (b) is from 1:1 to 1000:1;B) from 0.1% by weight, of a peroxy acid bleaching compound precursor; andC) the balance carriers and adjunct ingredients.

Owner:THE PROCTER & GAMBLE COMPANY

Oral care compositions with film forming polymers

ActiveUS20080233058A1Low costImprove convenienceCosmetic preparationsToilet preparationsAlcoholPolymer chemistry

Oral care compositions comprising:a) an oral care active; andb) an acrylic film forming polymer.In various embodiments, such polymers comprise monomeric units such as acrylic acid, methacrylic acid, acrylates, and combinations thereof. In one embodiment, the film forming polymer comprises a copolymer of a first monomeric unit selected from the group consisting of acrylic acid, methacrylic acid, and combinations thereof, with a second monomeric unit selected from the group consisting of acrylates, acrylamides, acetates, and combinations thereof. In various embodiments, the polymer is a terpolymer comprising a combination of the second monomeric units. Preferably, the composition additionally comprises a lower alcohol, such as ethanol. In various embodiments, the oral care active comprises a whitening material, such as a peroxide.

Owner:COLGATE PALMOLIVE CO

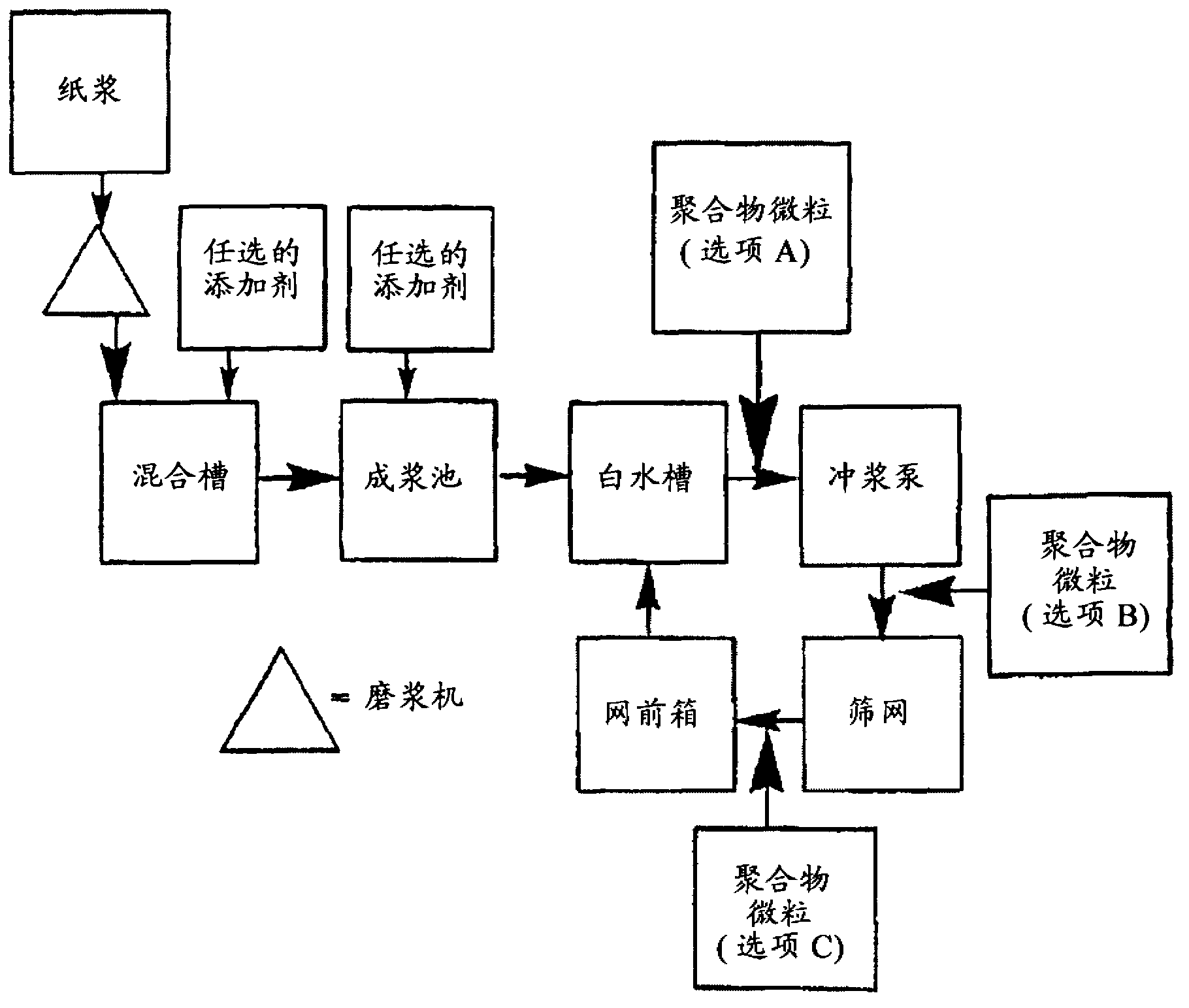

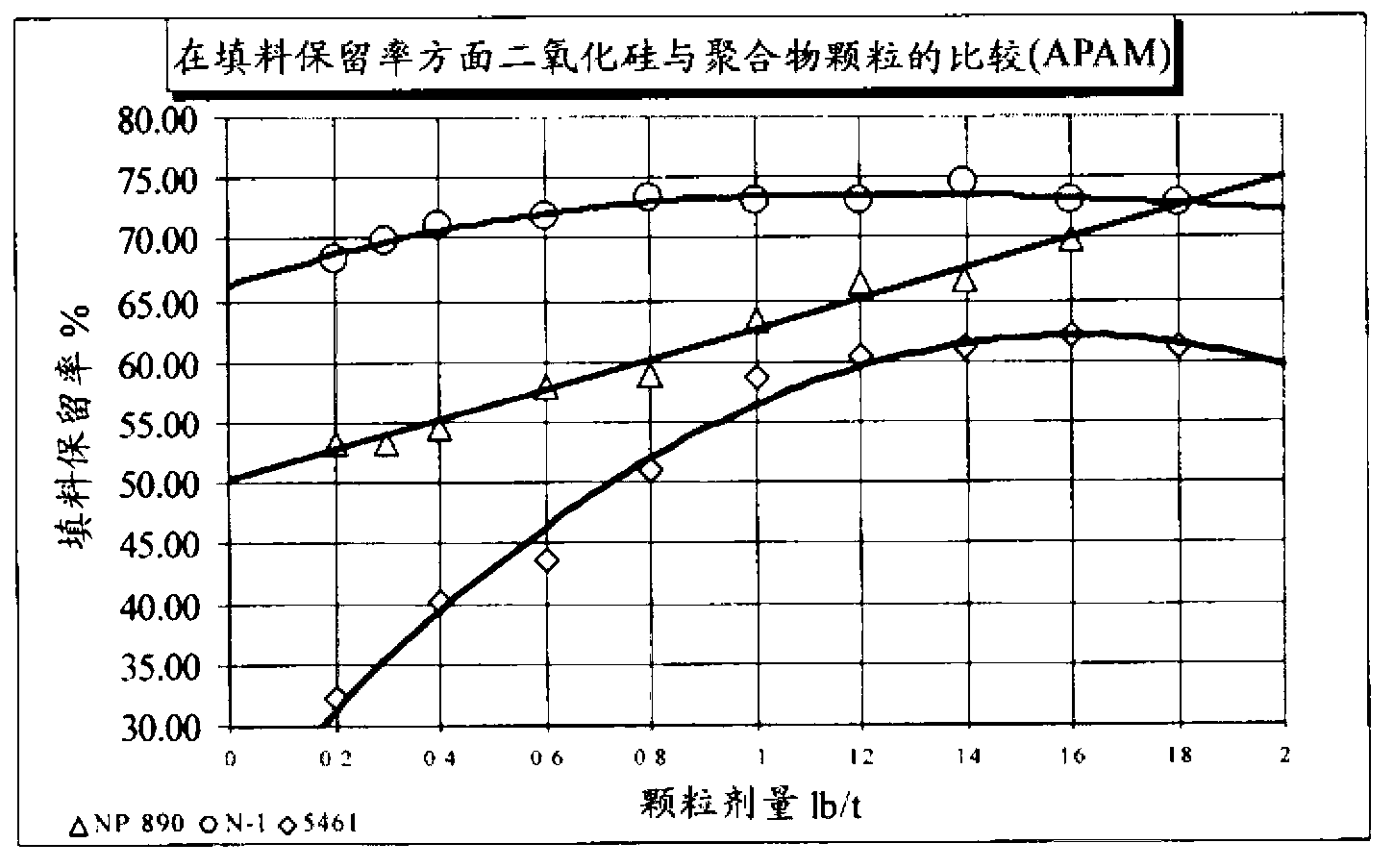

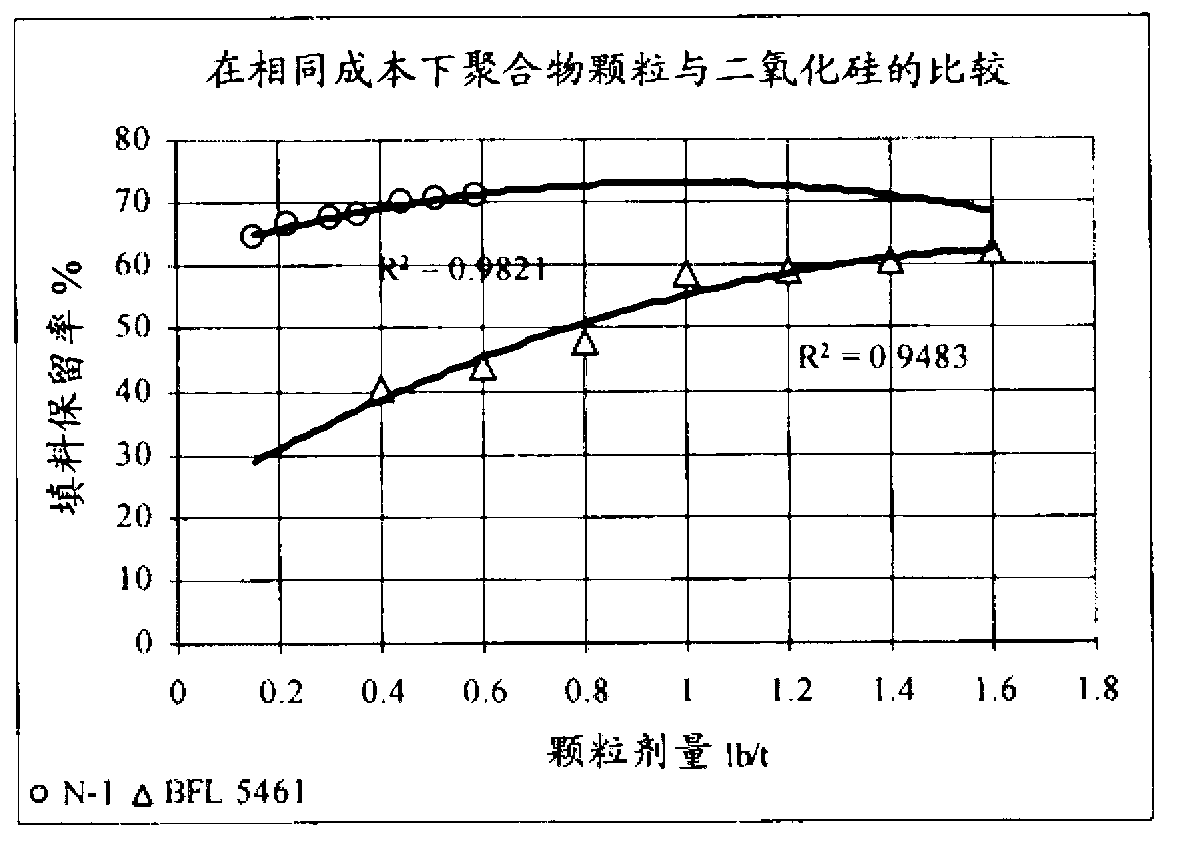

Papermaking and products made thereby with ionic crosslinked polymeric microparticle

Enhancement of papermaking drainage and retention properties of aqueous cellulosic suspensions used for production of paper or paper board with a retention / drainage additive system including ionic crosslinked acrylic acid-acrylate copolymer microparticles is described. Paper and paperboard products made with these copolymer microparticles are also described.

Owner:BUCKMAN LAB INT INC

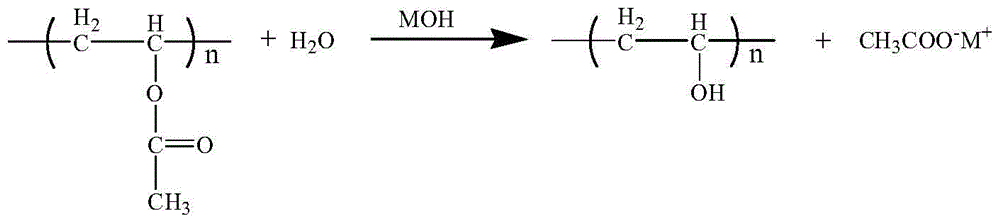

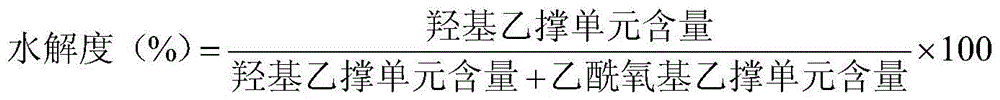

Water-soluble thin film with good water dissolving performance and small bag prepared from water-soluble thin film

The invention discloses a water-soluble thin film with a good water dissolving performance and a small bag prepared from the water-soluble thin film. The thin film is prepared from allyl acetate and a hydrolyzed derivative of a polymer of a second monomer; the thin film meets the following conditions: (a1) the hydrolyzing degree of the polymer is 90 percent to 99.5 percent; (a2) the viscosity of a water solution of the thin film with the mass percent of 4 percent is 10 centipoises to 25 centipoises; (a3) the thickness of the thin film is 70 microns to 85 microns; (a4) the second monomer is an acrylic monomer. The second monomer is selected from one of acrylic acid, methacrylic acid, acrylate or methacrylate. Before being subjected to ageing treatment, the single small bag prepared from the thin film is completely dissolved in one liter of water within 5 minutes; after being subjected to the ageing treatment, the single small bag prepared from the thin film is completely dissolved in one liter of water within 10 minutes, so that the water-soluble thin film has the very good water dissolving performance.

Owner:SUN YAT SEN UNIV +1

Resin composition for automotive parts

InactiveUS7553887B2Excellent in flowabilityMaintain good propertiesFilm/foil adhesivesOrganic dyesElastomerPolymer science

To provide a resin composition comprising a polypropylene resin composition and an aluminum flake pigment for use as an automotive resin composition, which is excellent in mechanical strength, physical properties and flowability, and enables to produce molded products showing good metallic appearance.A composition comprising a crystalline propylene / ethylene block copolymer, an elastomeric polymer and an inorganic filler is a preferred example of the polypropylene resin composition, and aluminum flakes surface-coated with a polymer containing as constituent units acrylic acid, an acrylic acid ester, epoxylated polybutadiene and divinylbenzene are preferred examples of the aluminum flake pigment.

Owner:PRIME POLYMER CO LTD

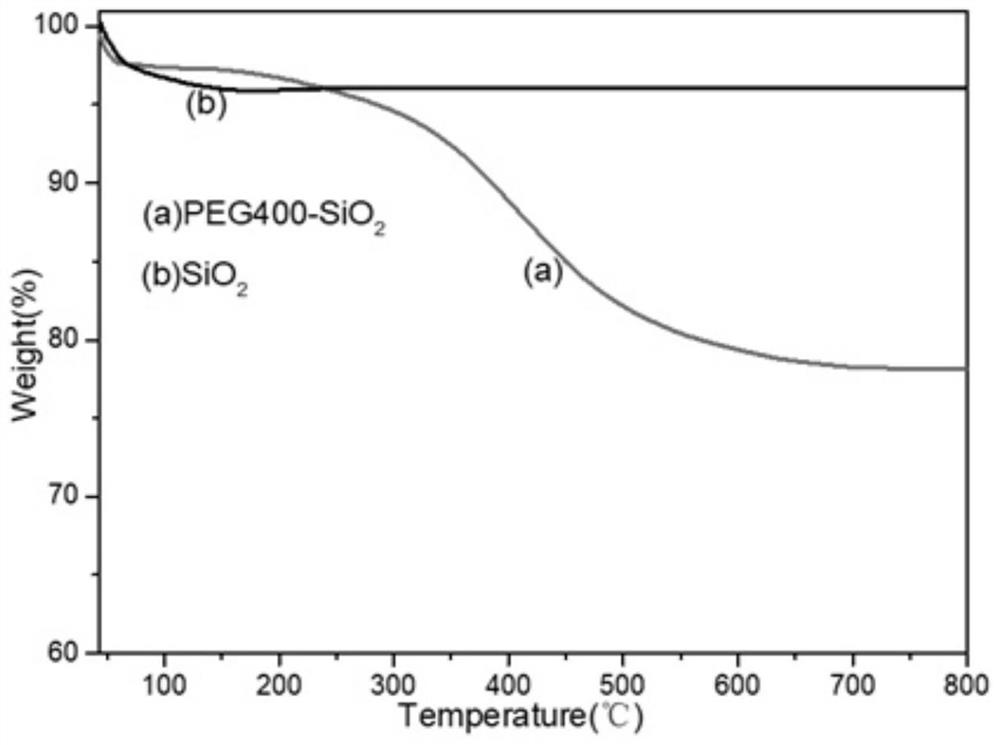

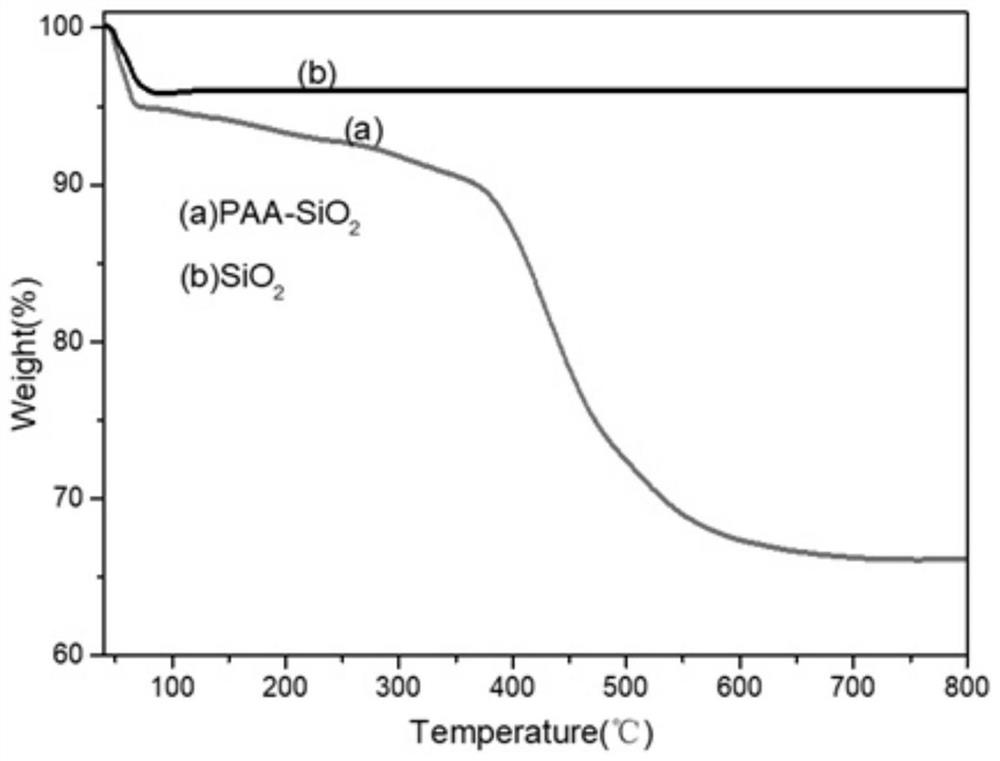

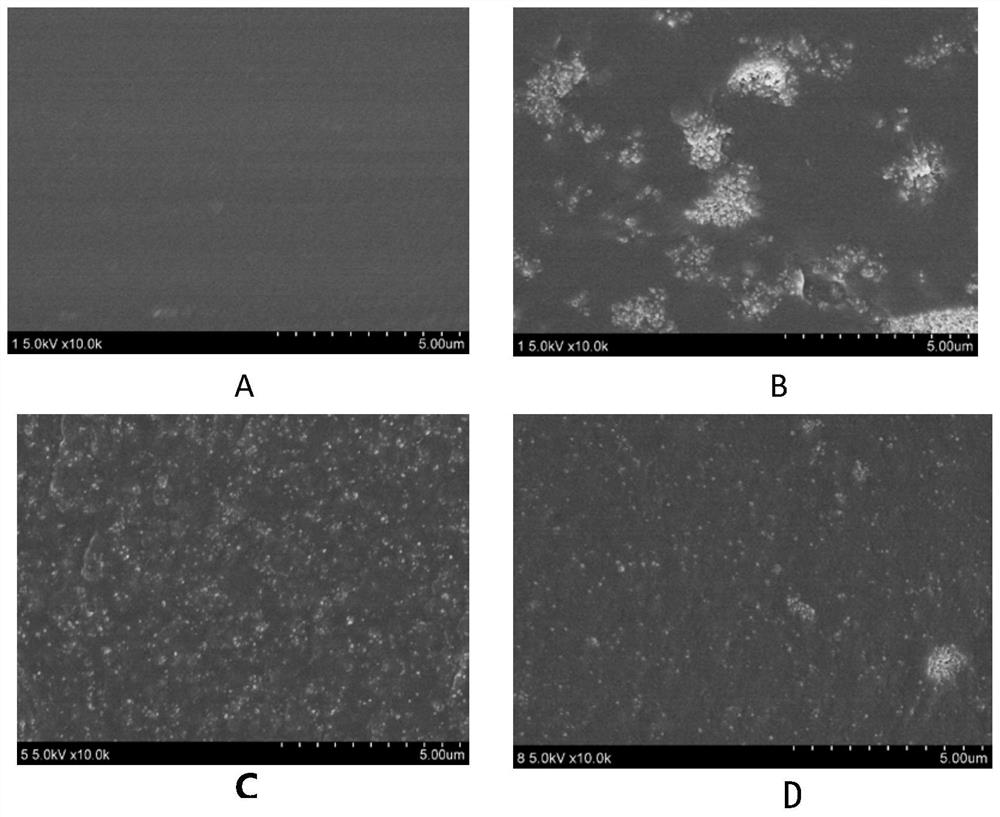

Core-shell structure nanoparticle and preparation method of hardened water-based acrylic resin coating

The invention discloses a core-shell structure nanoparticle and a preparation method of a hardened water-based acrylic resin coating. The preparation method comprises the following steps: preparing silane coupling agent modified nano SiO2, and grafting a polymer on the surface of the modified nano SiO2 to react, thereby obtaining the nano SiO2 composite particle with the core-shell structure. Thewater-based acrylic resin is obtained by emulsion polymerization of monomers such as acrylic acid and acrylic ester and an initiator. The prepared coating comprises the following components in parts by weight: 70-90 parts of water-based acrylic resin, 1-20 parts of deionized water, 0.5-10 parts of a coalescing agent, 0.1-3 parts of a wetting dispersant, 0.1-3 parts of a leveling agent, 0.1-5 partsof a thickener, 0.05-3 parts of an antifoaming agent and 1-10 parts of core-shell nanoparticles. The single-component water-based acrylic resin coating disclosed by the invention is full in paint film, low in VOC content and excellent in adhesive force, glossiness and impact resistance, and meets the performance requirements of the water-based paint coating industry, and the hardness reaches 2H or above.

Owner:科思创树脂制造(佛山)有限公司 +1

Macroporous crosslinked antibacterial macromolecular resin containing halamine functional group, as well as preparation and application thereof

InactiveCN105111367AImprove surface hydrophilicityThe synthesis process is green and environmentally friendlyBiocideDisinfectantsFoaming agentMacromolecule

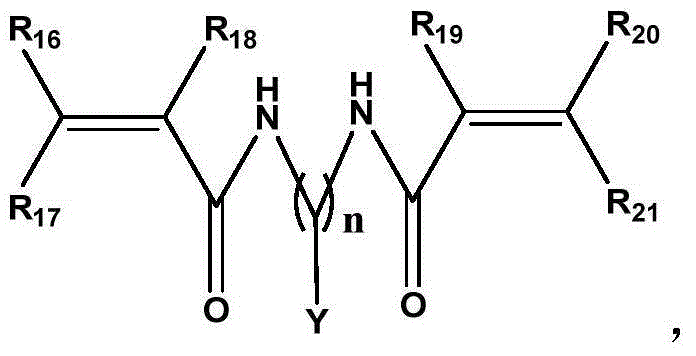

The invention relates to a macroporous crosslinked antibacterial macromolecular resin containing a halamine functional group, as well as preparation and application thereof. According to the preparation, acrylic acid, acrylate, acrylamide and the like serving as monomers of polymerization, an amide crosslinking agent serving as a crosslinking agent of polymerization, and benzene, methylbenzene, xylene and the like serving as a pore-foaming agent perform a polymerization reaction under the action of an initiator to generate a macroporous crosslinked copolymer resin containing a halamine functional group; and the macroporous crosslinked antibacterial macromolecular resin containing a halamine functional group is generated by means of a halogenating reaction of the halamine functional group. Compared with the prior art, the antibacterial macromolecular resin has a quick, effective and broad-spectrum antibacterial effect, can be widely applied to sterilization and disinfection treatment of various water bodies and air and control of harmful unpleasant gases, and can be subjected to certain mixing treatment with other materials to prepare various sanitary antibacterial products, such as antibacterial mattress protectors, antibacterial carpets, antibacterial diapers and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Resin composition for automotive parts

InactiveUS20050250892A1Improve liquidityImprove balanceFilm/foil adhesivesOrganic dyesElastomerPolymer science

To provide a resin composition comprising a polypropylene resin composition and an aluminum flake pigment for use as an automotive resin composition, which is excellent in mechanical strength, physical properties and flowability, and enables to produce molded products showing good metallic appearance. A composition comprising a crystalline propylene / ethylene block copolymer, an elastomeric polymer and an inorganic filler is a preferred example of the polypropylene resin composition, and aluminum flakes surface-coated with a polymer containing as constituent units acrylic acid, an acrylic acid ester, epoxylated polybutadiene and divinylbenzene are preferred examples of the aluminum flake pigment.

Owner:PRIME POLYMER CO LTD

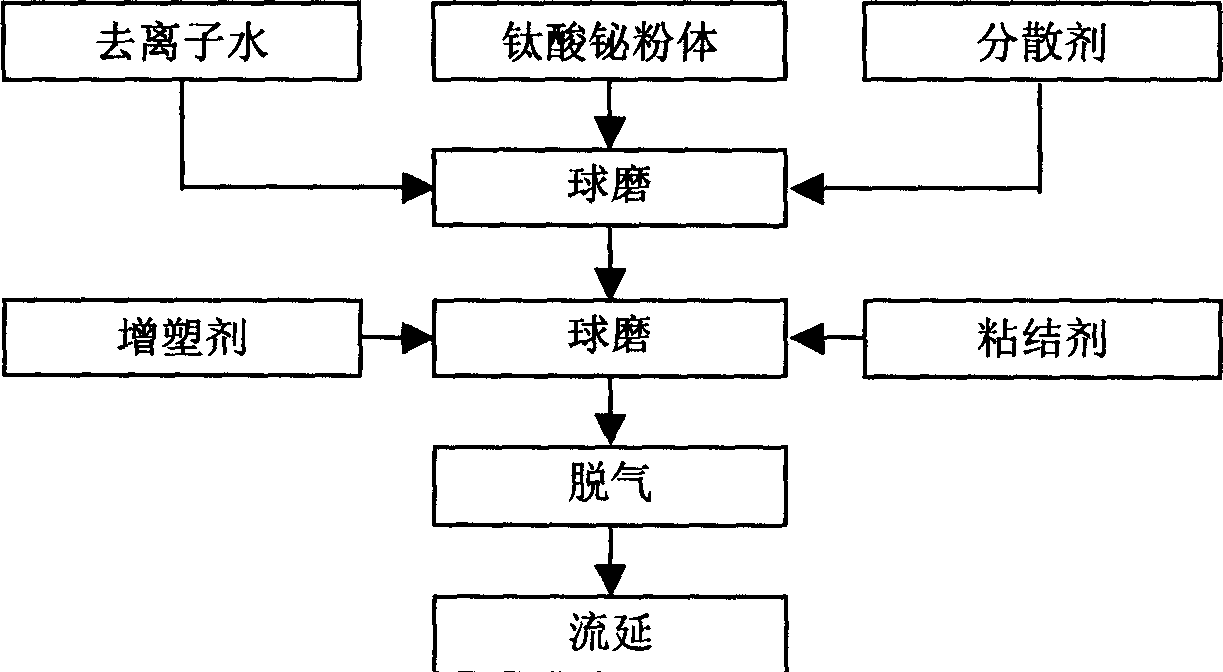

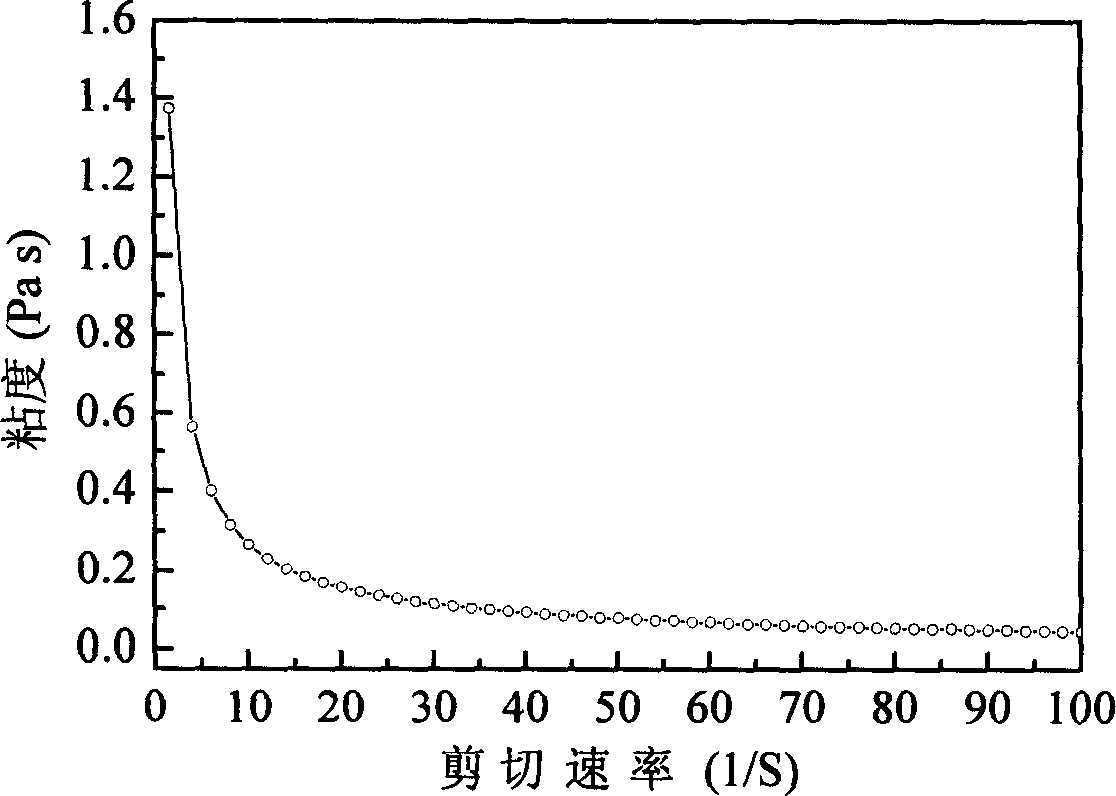

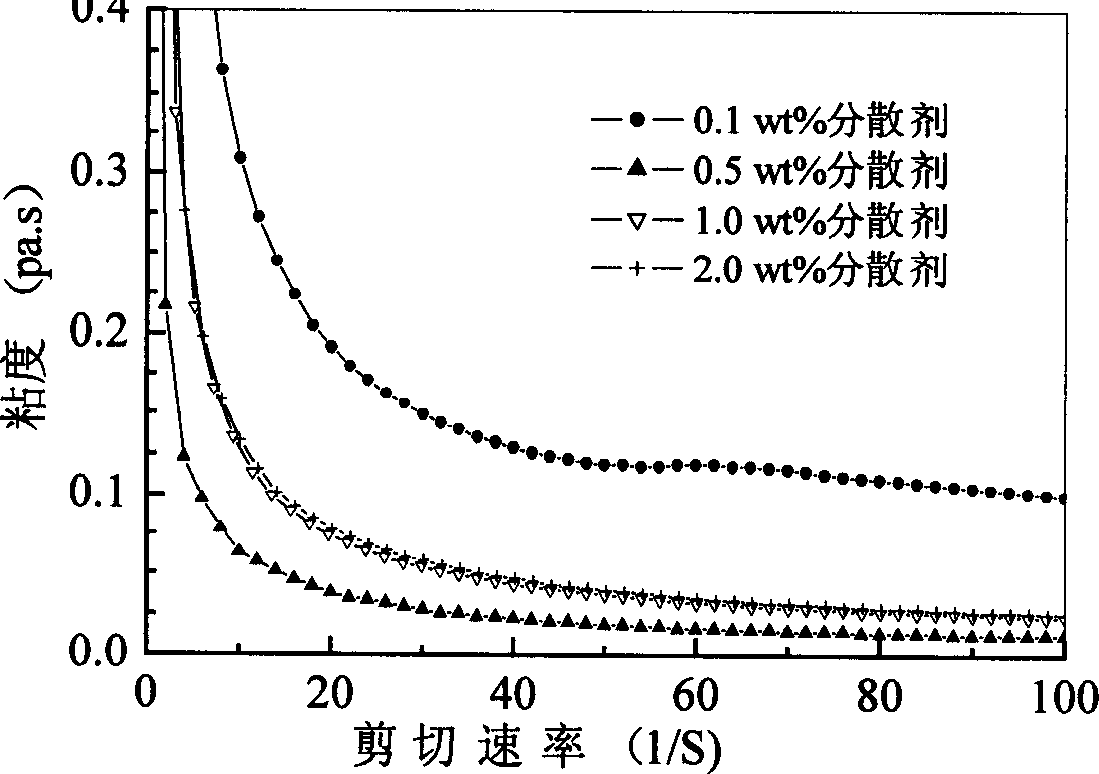

Nanometer bismuth titanate aqueous casting slurry and preparation method thereof

The invention relates to the dispersion in water of nano bismuth titanate powder and its water-based casting slurry. Wherein, using water-soluble AA-acrylate copolymer as dispersant to disperse the nano bismuth titanate powder with size less than 180nm in water and prepare the suspension with high solid content and low viscosity and well stability; then obtaining the final slurry by adding adhensive and plasticizer from AA-acrylate copolymer, polyvinyl alcohol ,glycerin and ether. Wherein, the final content in slurry comprises: 60-80wt% solid, 0.3-4.0wt% copolymer, 4-10wt% polyvinyl alcohol, 2.5-7.0wt% glycerin and 1.25-3.5wt% ether. The final product has well property and even distribution of powder size and air pore.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

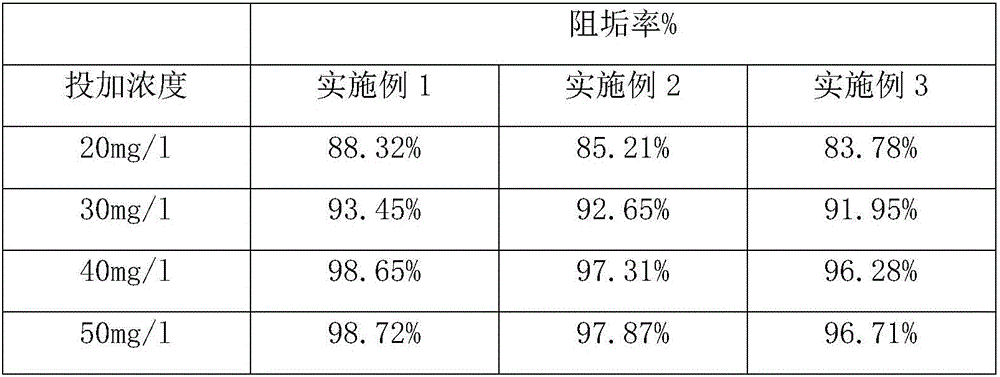

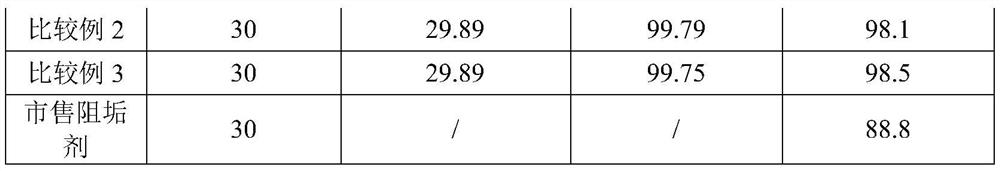

Green and environment-friendly composite scale and corrosion inhibition chemical and preparation method thereof

InactiveCN106007017AGood dispersionGood corrosion inhibition effectTreatment using complexing/solubilising chemicalsNon-contaminated water treatmentHigh concentrationPhosphate

The invention relates to a green and environment-friendly compound scale and corrosion inhibitor agent and its preparation method. The composition and mass parts of the agent are as follows: polyamino polyether group methylene phosphonic acid: 10-20 parts, polyol phosphate : 15-25 parts, polyepoxysuccinic acid: 5-15 parts, acrylic acid-acrylate-sulfonate copolymer: 10-20 parts, anhydrous zinc chloride: 5-15 parts, co-solvent : 1-10 parts, water: 20-40 parts. The components of the composite antiscaling and corrosion inhibiting agent of the present invention have a good synergistic effect, so that the compounding agent has excellent scale and corrosion inhibiting properties. The calcium ion tolerance is high, and the scale inhibition rate can reach 98% according to the standard measurement. It is especially suitable for industrial circulating water with a water temperature of 50°C-60°C. It has excellent scale and corrosion inhibition performance when used in circulating cooling water systems with high concentration, high temperature, and high alkalinity.

Owner:鞍钢栗田(鞍山)水处理有限公司

Pressure-sensitive adhesive for optical films

ActiveUS8236417B2Uniform and superior propertyGood storage stabilityFilm/foil adhesivesSynthetic resin layered productsPolymer scienceAcrylate polymer

A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. Preferably, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

Process for producing alkyl acrylate

ActiveUS10000439B2Preparation by ester-hydroxy reactionOrganic compound preparationTransesterificationAcrylyl-CoA

Owner:ARKEMA FRANCE SA

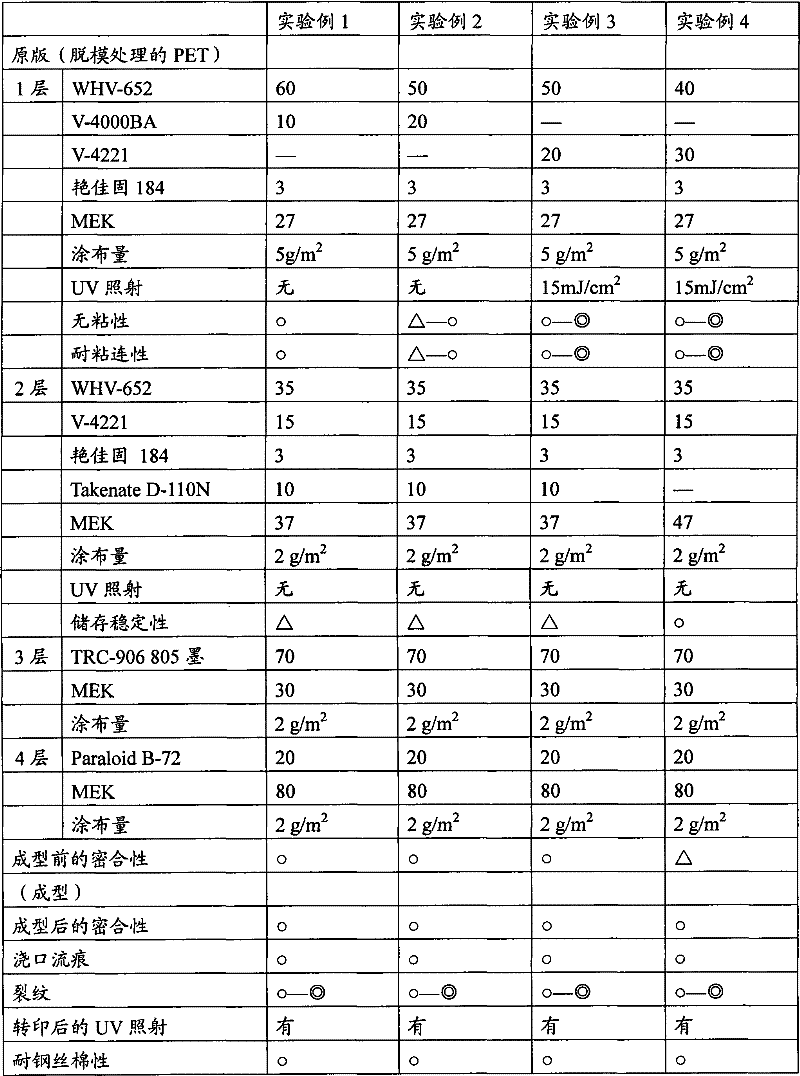

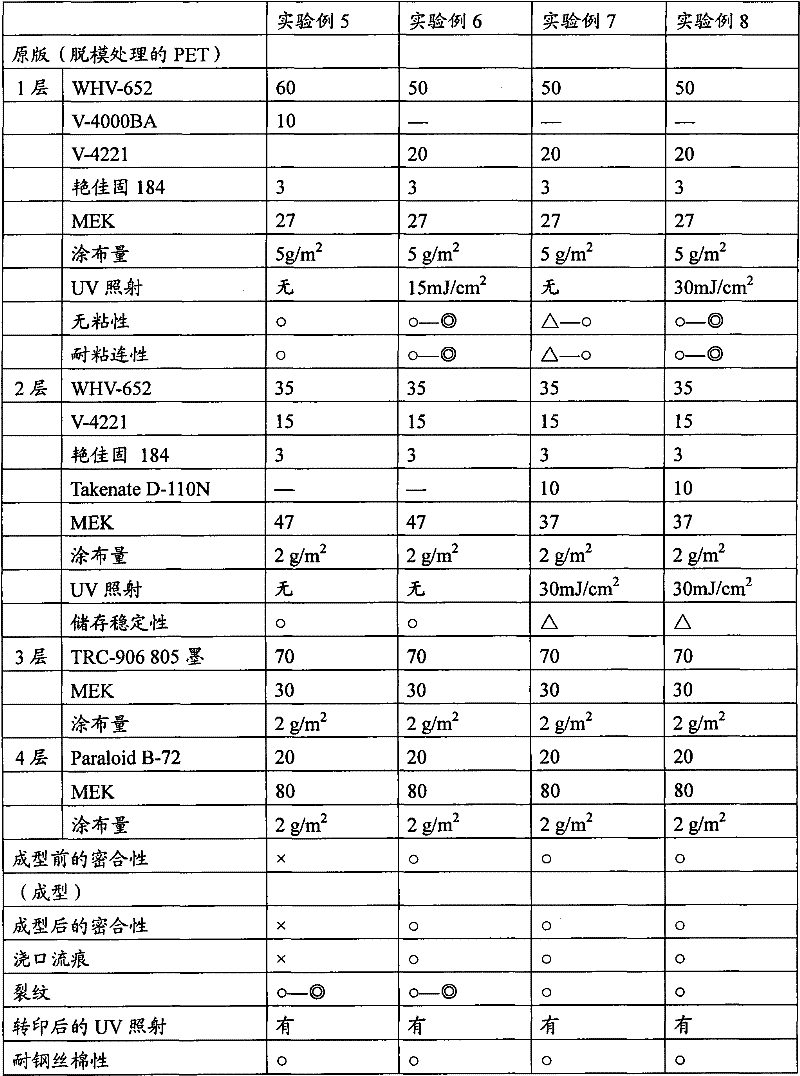

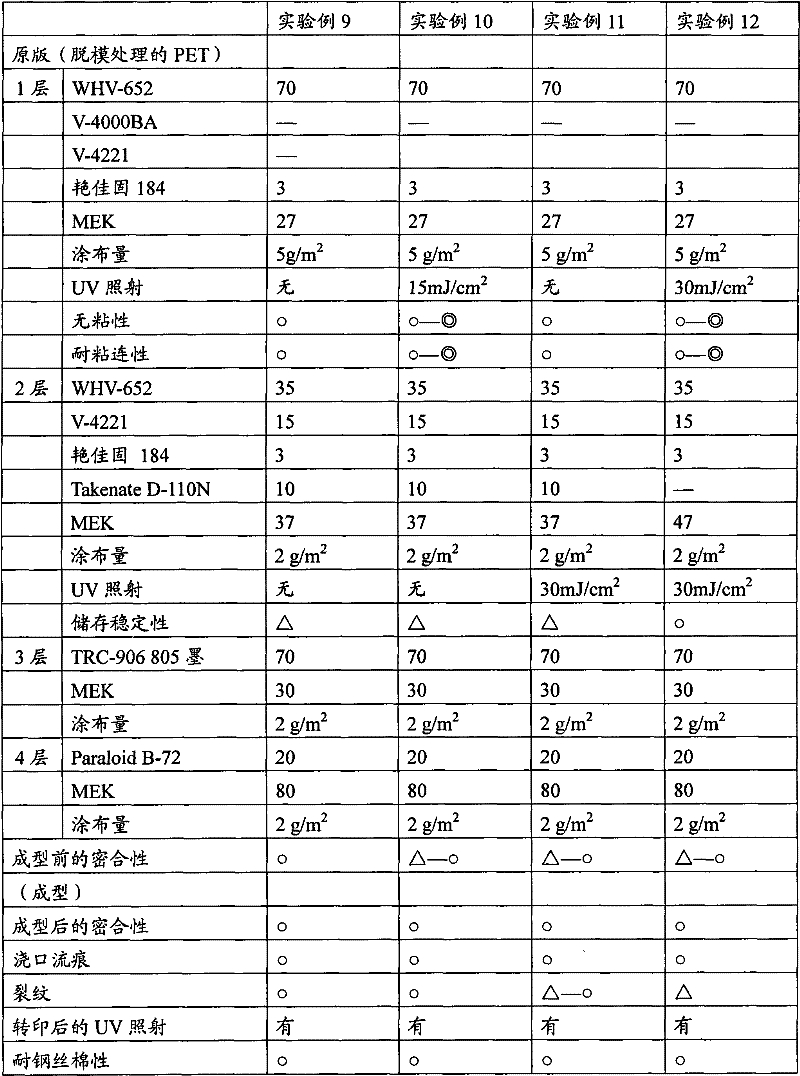

Active energy ray curing transfer sheet and manufacture method thereof

ActiveCN102673211AExcellent adhesionExcellent surface hardnessSynthetic resin layered productsCoatingsHeat resistancePolymer chemistry

The invention provides a transfer sheet for active energy ray curing intra-mold forming and a manufacture method thereof, wherein the transfer sheet has excellent adhesion resistance and sealing performance and heat resistance during forming. The transfer sheet for active energy ray curing intra-mold forming is characterized in that primer agent composites are used for half-curing, wherein the primer agent composites contain active energy ray curing crylic acid acrylic ester resin with hydroxyl and (methyl) acryloyl groups and / or active energy ray curing carbamic acid ester acrylic ester resin and polyisocyanate compounds; or active energy ray curing crylic acid acrylic ester resin and / or active energy ray curing carbamic acid ester acrylic ester resin curing hard coating and / or curing primer coating are used for half curing.

Owner:DIC CORP

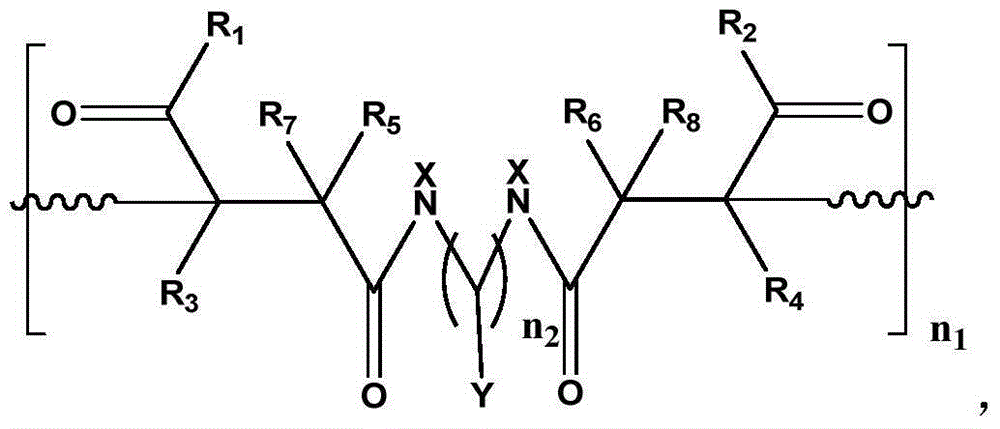

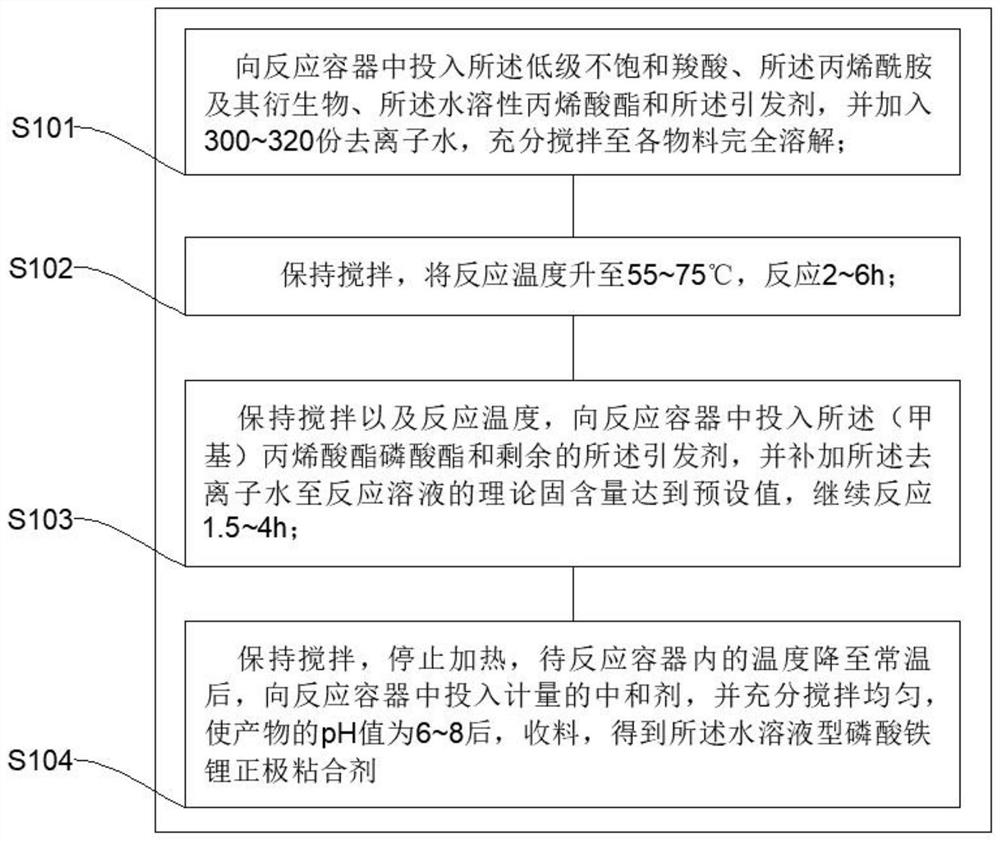

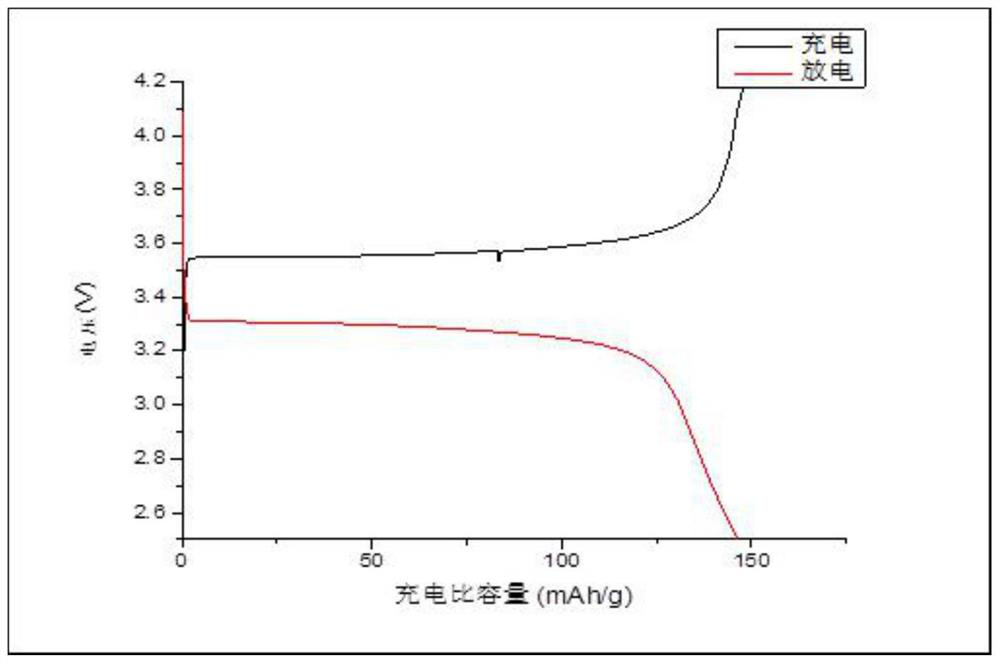

Aqueous solution type lithium iron phosphate positive electrode adhesive and preparation method and application thereof

PendingCN112467142AImprove thermal stabilityGood storage stabilitySecondary cellsPositive electrodesMethacrylatePhosphoric Acid Esters

The invention discloses an aqueous solution type lithium iron phosphate positive electrode adhesive, and a preparation method and application thereof. The aqueous solution type lithium iron phosphatepositive electrode adhesive is an aqueous solution, and the solid content is 3-15%; at 25 DEG C, the viscosity of the aqueous solution type lithium iron phosphate positive electrode binder is 5000-100000 cp, and the pH value is 6-8; the aqueous solution type lithium iron phosphate positive electrode adhesive comprises the following components in parts by mass: 10-20 parts of low-grade unsaturatedcarboxylic acid, 8-15 parts of acrylamide and derivatives thereof, 5-20 parts of water-soluble acrylate, 5-10 parts of (methyl) acrylate phosphate ester, and 0.1-0.4 part of initiator. Compared with the prior art, a single-component aqueous solution system is adopted, compared with a multi-component blending solution, the storage and use stability is better, the formula is simpler, and preparationis easy and convenient; in the aspect of components, acrylic acid, acrylate, acrylamide and other monomers are adopted for copolymerization, and the product has better thermal stability than polyvinyl alcohol, CMC and other water-soluble polymers.

Owner:湖南高瑞电源材料有限公司

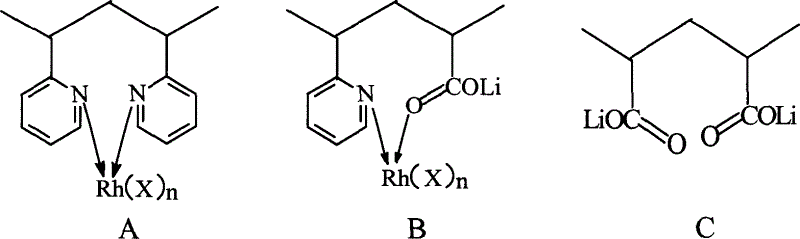

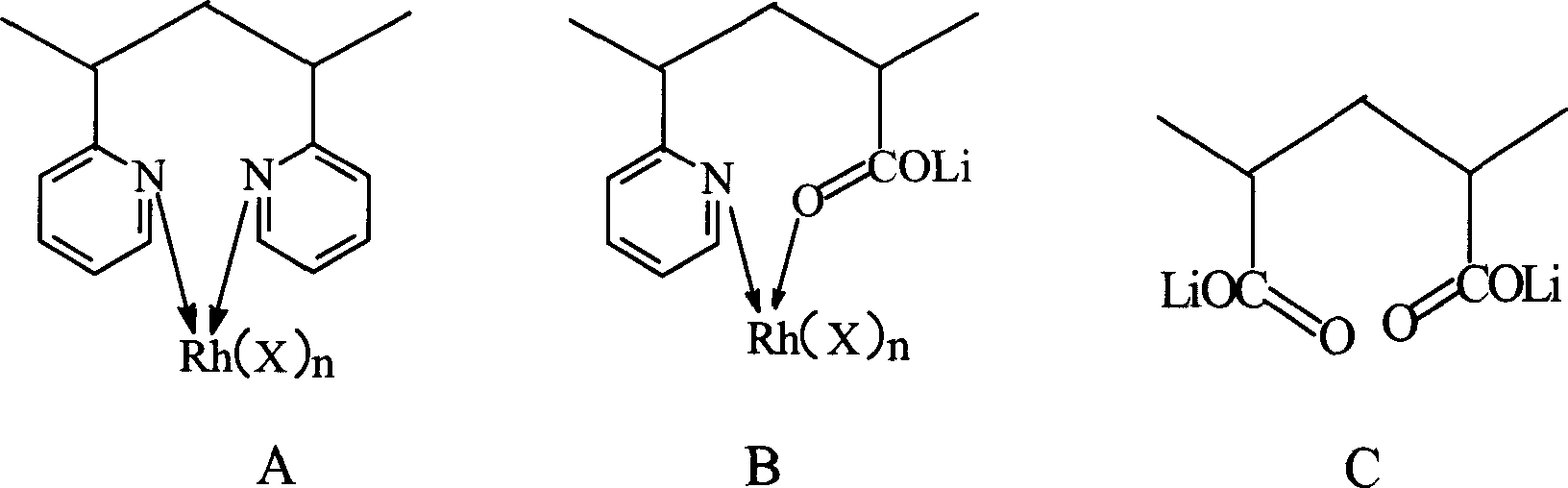

Copolymer ligand rhodium-lithium bimetal catalyst and its manufacturing method and application

InactiveCN1517151AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reaction2-VinylpyridineLithium hydroxide

A bimetal Rh-Li catalyst for the hydroxylation reaction of methanol to obtain acetic acid or the carbonylating reaction of methyl acetate to obtain ethylanhydride is disclosed, which has 3 basic structures and features high activity, selectivity and stability. Its preparing process includes such steps as copolymerization of 2-vinylpyridine or 4-vinylpyridine on acrylic acid, acrylate, or maleic acid anhydride, hydrolzying by strong alkali, acting on lithium hydroxide to obtain ligand, reacting on Rh compound and coordination.

Owner:INST OF CHEM CHINESE ACAD OF SCI

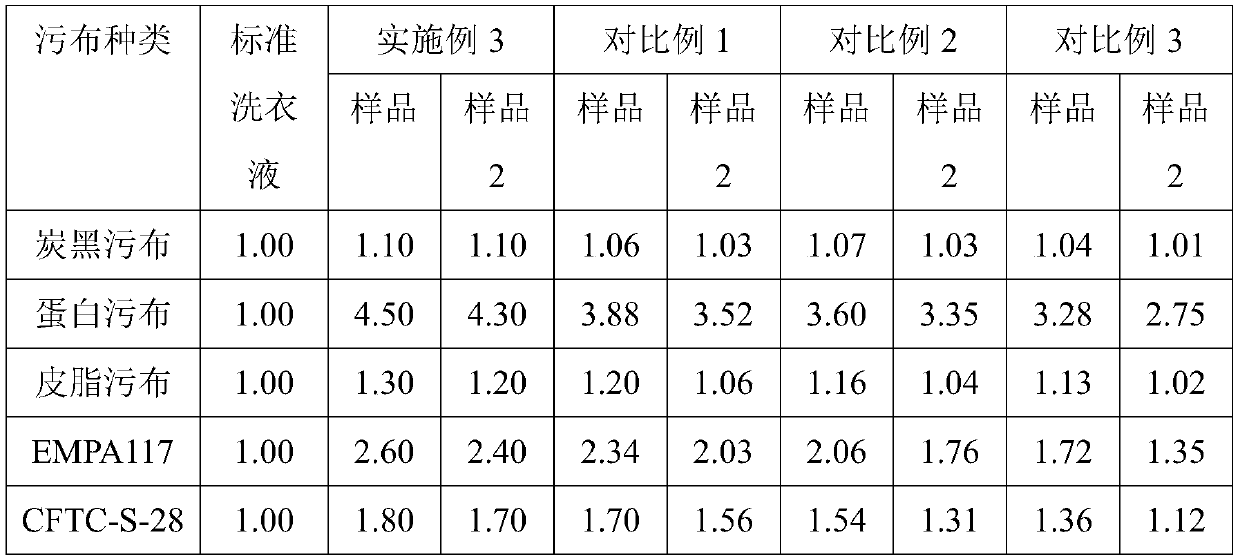

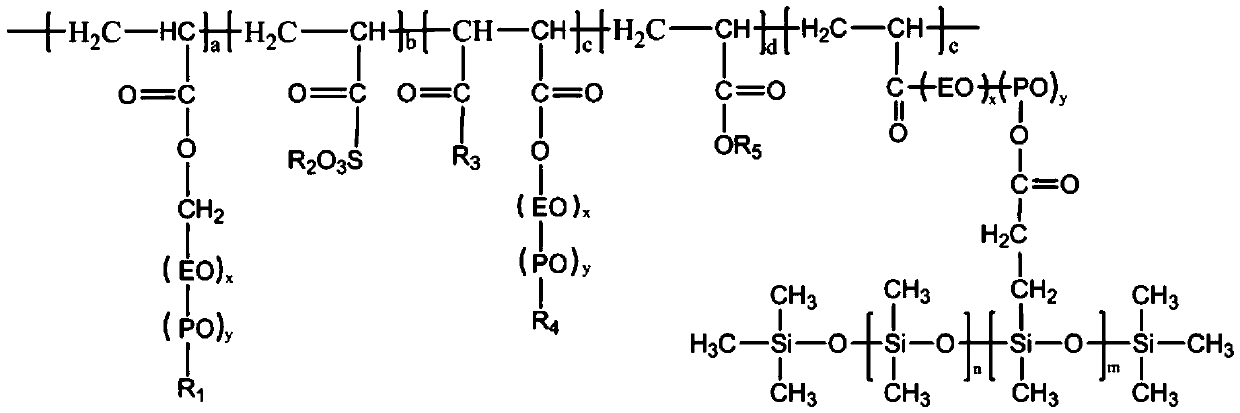

A kind of laundry pod and preparation method thereof

ActiveCN108893212BEfficient removalMaintenance colorSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsGlycerolChemical products

The invention belongs to the technical field of daily chemical products and specifically relates to a clothes-washing gel bead and a preparation method thereof. The clothes-washing gel bead provided by the invention contains the following components by weight percent: 30-75% of fatty alcohol-polyoxyethylene ether, 5-15% of glycerinum, 10-20% of propylene glycol, 8-15% of potassium laurate, 5-20% of fatty acid methyl ester ethoxylate, 5-15% of deionized water, 1-5% of acrylic acid-acrylate copolymer, 1-5% of organic silicon compound, 1-5% of essence, 0.2-0.8% of complex enzyme, 0.1-0.6% of microcapsule essence, 0.1-0.5% of silver ion compound, 0.1-0.5% of glutamic acid N,N-tetrasodium acetoacetate, 0.01-0.2% of preservative, 0.001-0.005% of pigment and 0.05-0.2% of citric acid. The clothes-washing gel bead provided by the invention is efficient and safe, has long-lasting fragrance, is sterilizing and has a softening function.

Owner:WALCH GUANGZHOU COMMODITY

Corrosion and scale inhibiting agent for circulating cooling water

InactiveCN104628158APromote degradationHigh corrosion and scale inhibition performanceSpecific water treatment objectivesScale removal and water softeningEpoxyEutrophication

A corrosion and scale inhibiting agent for circulating cooling water is composed of the following raw materials in parts by weight: 20 to 30 parts of polyaspartic acid, 20 to 30 parts of polyepoxysuccinic acid, 5 to 20 parts of alkyl epoxy carboxylate, 10 to 20 parts of acrylic acid-acrylate-sulfonate copolymer, and 20 to 40 parts of purified water. The main components of the corrosion and scale inhibiting agent such as polyaspartic acid, polyepoxysuccinic acid, alkyl epoxy carboxylate, and the like have an excellent biodegradability and a high corrosion and scale inhibiting performance, and the corrosion and scale inhibiting agent is a green water treatment agent. The agent does not contain any phosphorus and thus will not form calcium phosphate scales during the application process. The discharged sewage will not generate eutrophication pollution. The corrosion and scale inhibiting agent can be used without a membrane, is convenient to use, has the advantages of little using amount and low cost, reduces the operation cost of circulating water, and assists the management of circulating water.

Owner:XIAN RUNDA CHEM TECH

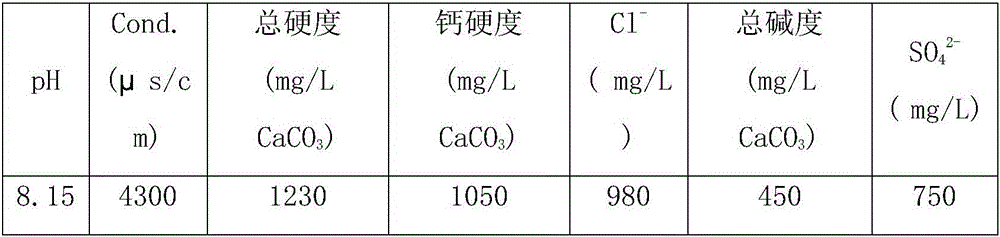

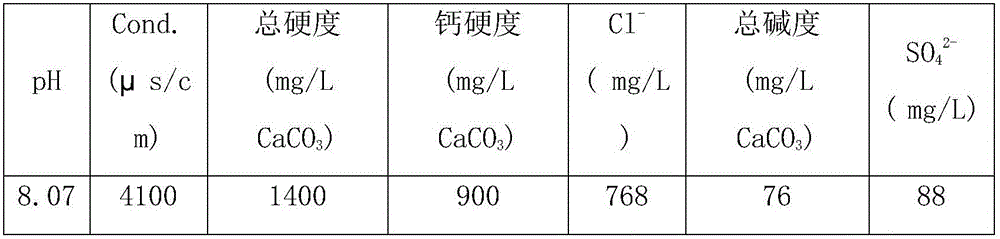

Antiscale corrosion inhibitor for recycling reclaimed water and preparation method thereof

InactiveCN102730846AReduce the impactExtended operating cycleTreatment using complexing/solubilising chemicalsMeth-Tungstate

The invention discloses an antiscale corrosion inhibitor for recycling reclaimed water and a preparation method thereof. The antiscale corrosion inhibitor for recycling reclaimed water is prepared from the following components in percentage by weight: 25-30% of phosphine-containing acrylic acid-acrylate-maleic acid multielement multipolymer, 30-35% of phosphine-containing acrylic acid-acrylate-AMPS (2-acrylamido-methylpropanesulfonic acid) multielement multipolymer, 7-10% of gluconate, 1-1.5% of azole, 1-1.5% of tungstate, 4-8% of zinc salt and 15-30% of water. The antiscale corrosion inhibitor for recycling reclaimed water is suitable for recycling high-hardness high-alkalinity reclaimed water in the representative smelting industry into an industrial circulation cooling water system, has favorable antiscale and corrosion inhibition properties, and can effectively prolong the operation cycle of production equipment, thereby creating beneficial conditions for the enterprise for saving the water resources, reducing the sewage discharge and protecting the environment.

Owner:北京盖雅技术中心有限公司

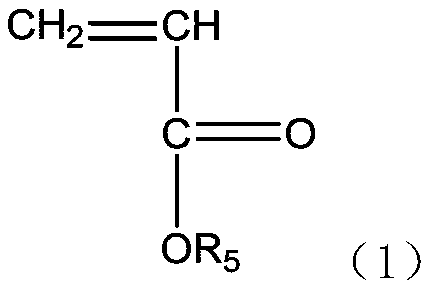

Shrinkage-reducing polycarboxylic acid type superplasticize, preparation method and application thereof

InactiveCN109970931AMature and simple production technologySimple production technologyReduction ratePolymer science

A shrinkage-reducing polycarboxylic acid type superplasticize, a preparation method and an application thereof are disclosed. Free radical copolymerization is performed on monomer A (5-50 parts), monomer B (1-60 parts), monomer C (20-100 parts), monomer D (10-60 parts) and monomer E (1-20 parts) in the presence of an initiator and a chain transfer agent, and finally a base is added to neutralize to adjust the PH to 7-8; wherein monomer A is acrylic acid, acrylic ester, acrylate or acrylic ester salt; monomer B is methacryl sulfonic acid or methacryl sulfonate; monomer C is a polyether monoacrylate or an alkoxy polyether monoacrylate; monomer D is maleic anhydride polyether ester, maleic anhydride hemi-ester, maleic anhydride polyether ester salt or maleic anhydride hemi-ester salt; monomerE is a copolymer of polysiloxane and acrylic acid modify polyether. The invention has features of wide source of raw materials, mature production technology, high water reduction rate, obvious enhancement effect, excellent air entrainment effect, good slump-retaining performance and anti-shrinkage and anti-drying crack.

Owner:NORTHWEST A & F UNIV

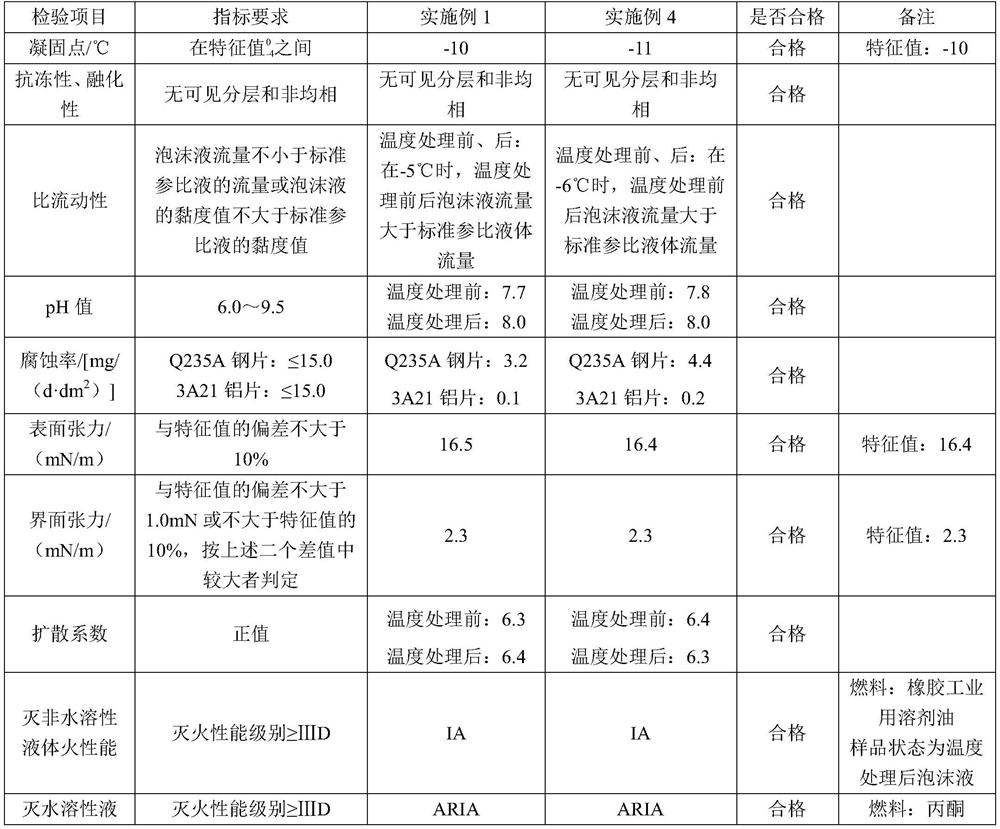

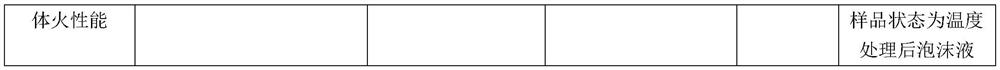

Foam fire extinguishing agent for automotive ethanol gasoline fire

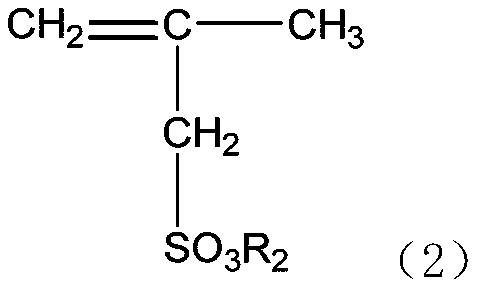

PendingCN114053643AAdequate isolationEffectively resist damageFire extinguisherFirefighting foamMaterials science

The invention provides a foam fire extinguishing agent for an automotive ethanol gasoline fire. According to the fire extinguishing agent formula, a film aid is added on the basis of a film-forming agent, wherein the film-forming agent is xanthan gum; and the film aid comprises at least one of an acrylic acid-maleic anhydride copolymer, an acrylic acid-acrylate copolymer and an acrylic acid-itaconic acid copolymer. The weight ratio of the film-forming agent to the film aid is (1-3): 4 in percentage by weight. The addition of the film aid ensures that the foam extinguishing agent for the automotive ethanol gasoline fire forms a compact and firm reinforced composite film with high air impermeability. The fire extinguishing speed is high when the foam fire extinguishing agent is used for the automotive ethanol gasoline fire, the anti-after-combustion capacity is high, and the good fire extinguishing performance can still be kept even in seawater quality. Meanwhile, the film aid is also suitable for the existing anti-dissolution foam fire extinguishing agent, and the strength and toughness of a fire extinguishing foam gel film can be improved and the fire extinguishing capacity can be enhanced by adding the film aid into the existing anti-dissolution foam fire extinguishing agent.

Owner:应急管理部天津消防研究所

Efficient environment-friendly pre-filming agent

PendingCN112626510AGood pre-film effectSave waterMetallic material coating processesSodium gluconatePhosphorus containing

The invention discloses an efficient environment-friendly pre-filming agent which comprises the following components in percentage by mass: 20%-40% of acrylate sulfonate copolymer, 1%-10% of sodium gluconate, 2%-10% of zinc salt, 0.5%-3% of benzotriazole, 0.5%-3% of concentrated sulfuric acid and the balance of water, wherein the solid content of the acrylate sulfonate copolymer is greater than or equal to 25.0%, and the number-average molecular weight of the acrylate sulfonate copolymer is 2000-15000; and the zinc salt is one or a mixture of two of zinc chloride and zinc sulfate. The pre-filming agent does not contain phosphorus, does not cause eutrophication to water quality during use, does not need to add acid to adjust the acidity of a solution during pre-filming of an industrial circulating water system, has a remarkable pre-filming effect, greatly shortens the pre-filming time, does not need system replacement and water quality discharge after pre-filming, and can be directly converted into normal operation of the system, thereby saving water resource and being friendly to the environment.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

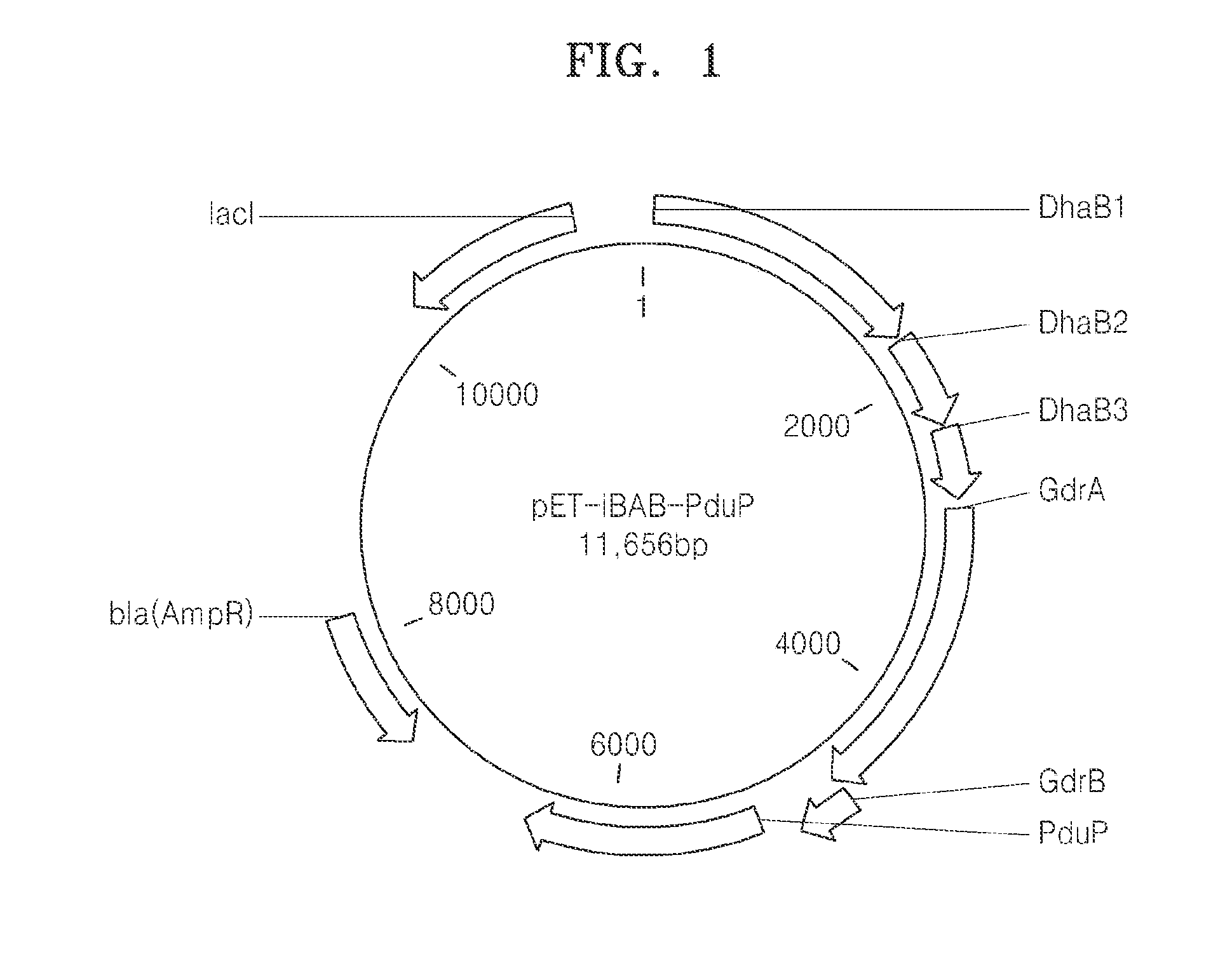

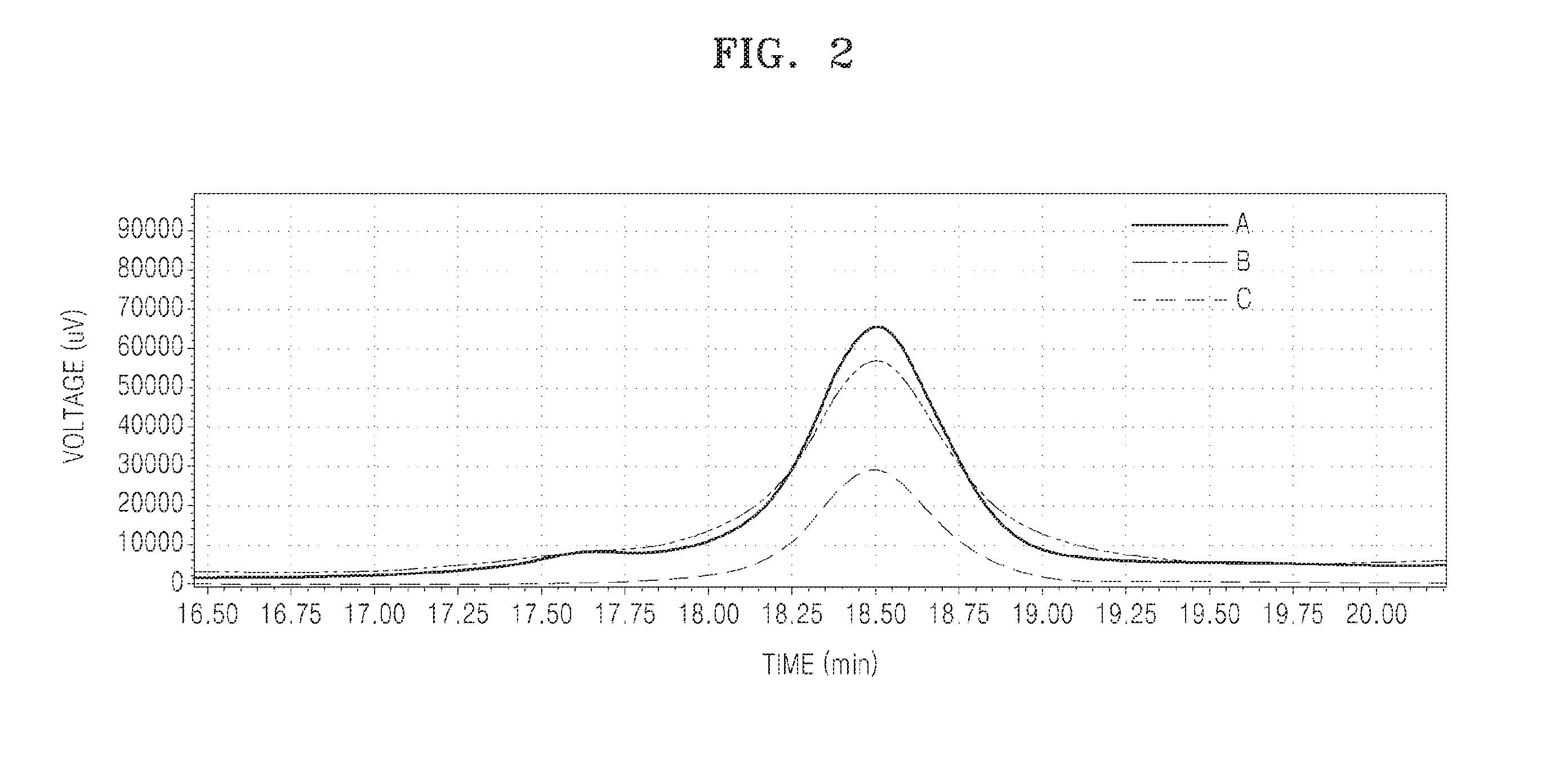

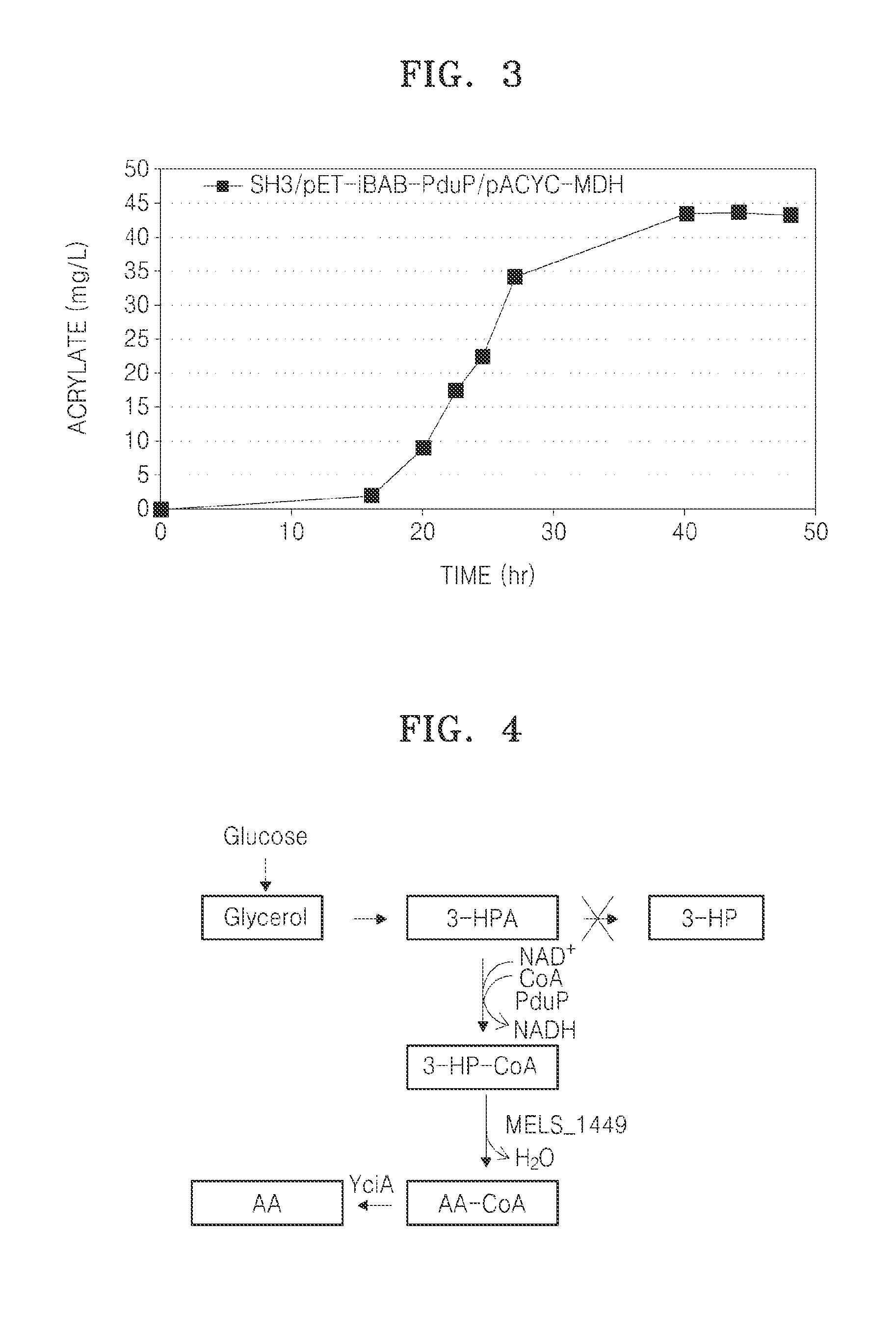

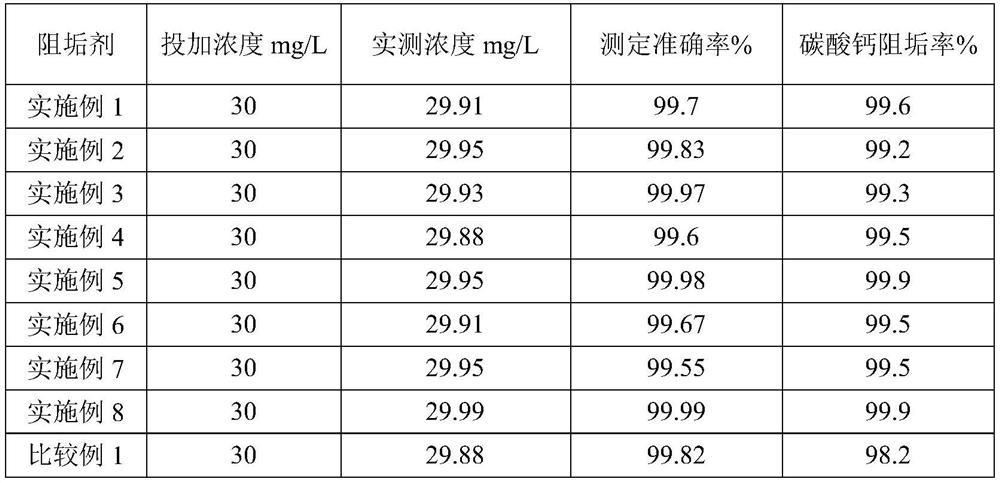

Microorganism having novel acrylic acid synthesis pathway having enhanced activity of coa acylating aldehyde dehydrogenase and method of producing acrylic acid using the same

A microorganism capable of producing acrylic acid, comprising a genetic modification that increases activity of CoA acylating aldehyde dehydrogenase (ALDH) catalyzing conversion of 3-hydroxypropionaldehyde (3-HPA) to 3-hydroxy propionyl-CoA (3-HP-CoA) and a genetic modification that increases activity of 3-HP-CoA dehydratase catalyzing conversion of 3-HP-CoA to acrylyl-CoA in the microorganism in comparison with a cell that is not genetically engineered; as well as a method of producing the microorganism, and a method of producing acrylic acid using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

Fluorescent phosphorus-free scale inhibitor and preparation method thereof

ActiveCN112079450AGood synergyGood anti-scaling effectScale removal and water softeningEster sulfonatePetrochemical

The invention provides a fluorescent phosphorus-free scale inhibitor and a preparation method thereof.The fluorescent phosphorus-free scale inhibitor is mainly prepared from, by mass, 10-15 parts of maleic acid-acrylic acid copolymer, 20-25 parts of polyepoxysuccinic acid, 15-20 parts of acrylic acid-sulfonic acid amide copolymer, 12-18 parts of acrylic acid ester sulfonate copolymer, 8-12 parts of an auxiliary scale inhibitor, 0.1-0.15 part of 1, 3, 6, 8-pyrene tetracarboxylic acid sodium salt and 10-15 parts of water. The fluorescent phosphorus-free scale inhibitor has the advantages of no phosphorus, high stability, and certain chlorine resistance and oxidation resistance, and can be applied to circulating cooling water systems in various industries such as chemical engineering, electric power, metallurgy, petrochemical engineering, central air conditioners and the like.

Owner:XINJIANG DELAND

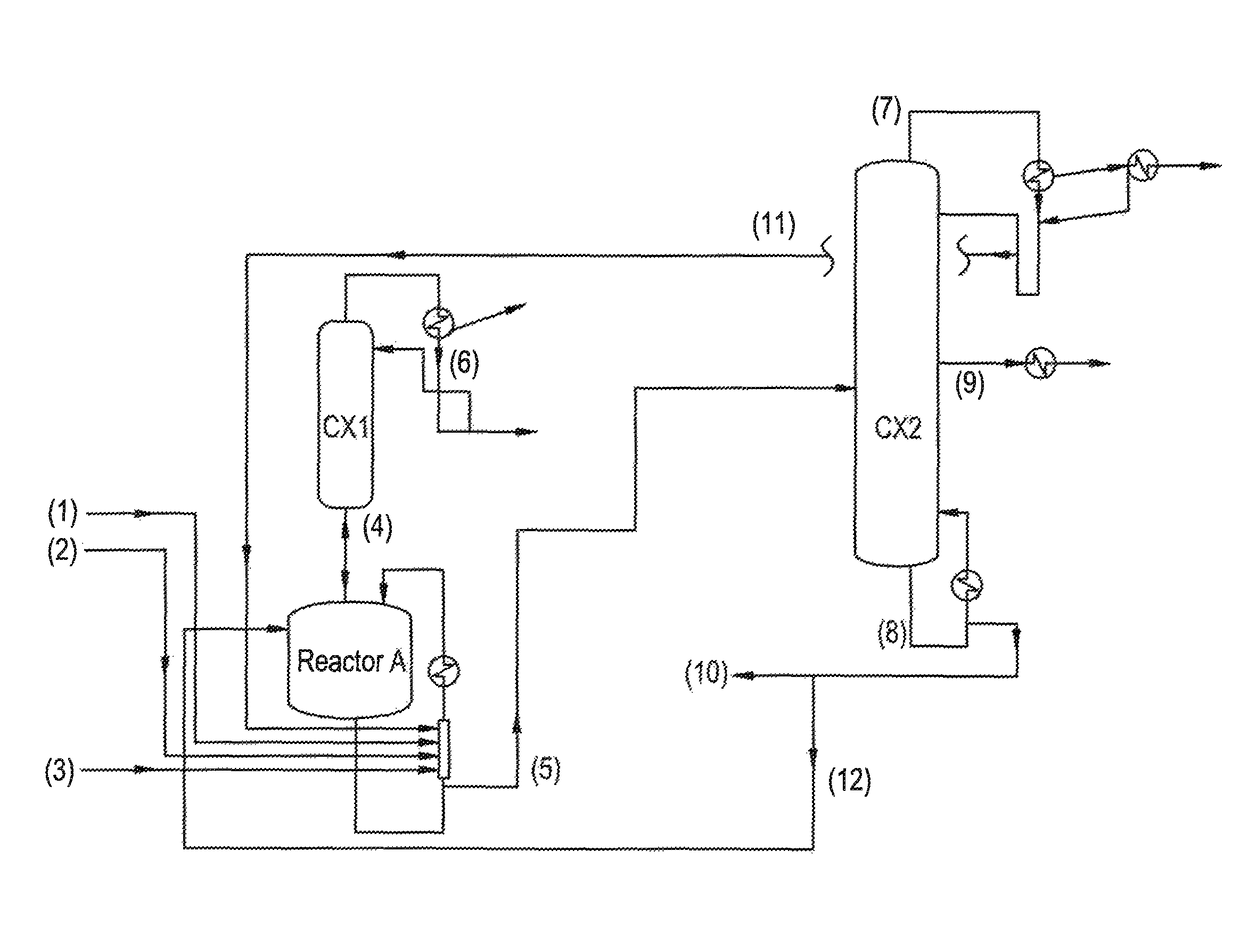

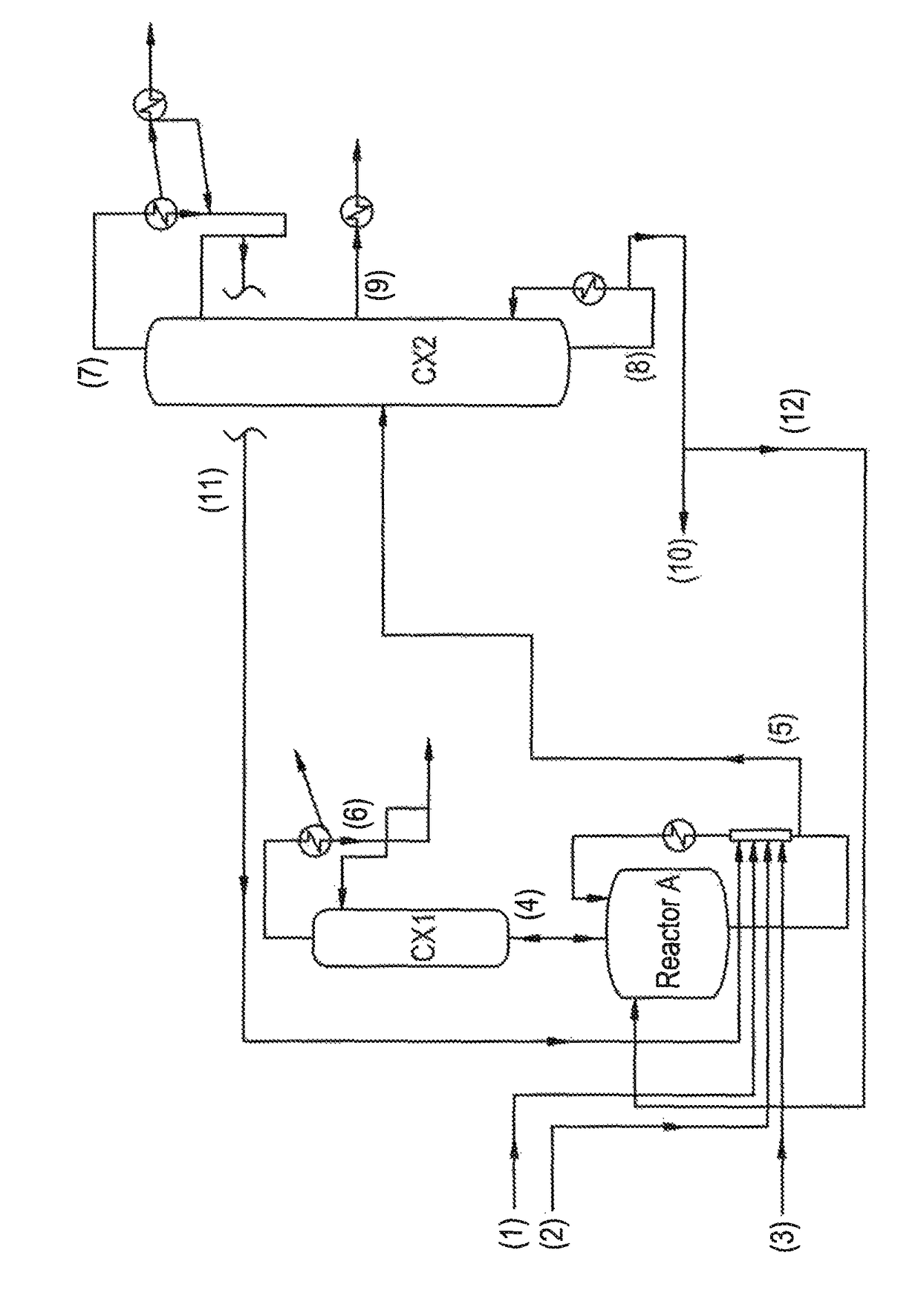

Process for producing alkyl acrylate

ActiveUS20150315120A1Reduce purification costsOrganic compound preparationPreparation by ester-hydroxy reactionTransesterificationAcrylyl-CoA

The invention relates to the production of alkyl acrylate according to a continuous transesterification process. In one embodiment the process of the invention uses a simple column to purify a reaction mixture of acryl acrylate in one step yielding alkyl acrylate with a purity of greater than 99.8%.

Owner:ARKEMA FRANCE SA

Phosphoric acid production equipment and pipeline cleaning scale removal method

InactiveCN104550139ASave cleanup timeSimple configurationNon-surface-active detergent compositionsHollow article cleaningO-Phosphoric AcidMeth-

The invention discloses phosphoric acid production equipment and a pipeline cleaning scale removal method. According to the method, amino tri (methylene phosphonic acid), phosphono carboxylic acid, acrylamide-sodium allylsulfonate copolymers, multipolymers, crylic acid-acrylic ester-sulphonate copolymers and slow-release agents are adopted for preparing a scale inhibitor, the mass percent of the amino tri (methylene phosphonic acid) in the scale inhibitor is 2 percent to 6 percent, the mass percent of the phosphono carboxylic acid is 2 percent to 6 percent, the mass concentration of the acrylamide-sodium allylsulfonate copolymers is 4 percent to 8 percent, the mass concentration of the multipolymers is 4 percent to 8 percent, the mass concentration of the crylic acid-acrylic ester-sulphonate copolymers is 2 percent to 6 percent, and the mass percent of the slow-release agents is 0.01 percent to 0.02 percent; then, after the scale inhibitor is stirred and heated, the scale inhibitor is added into phosphoric acid equipment and a conveying pipeline, so that scale blocks are soaked by the scale inhibitor, and the scale blocks can be cleaned and removed. When the method is adopted, the scale block cleaning time is shortened, the cleaning cost is reduced, the operation efficiency of the device is improved, the configuration of the scale inhibitos is simple, and the use is convenient.

Owner:ANHUI NEW ZHONGYUAN CHEM

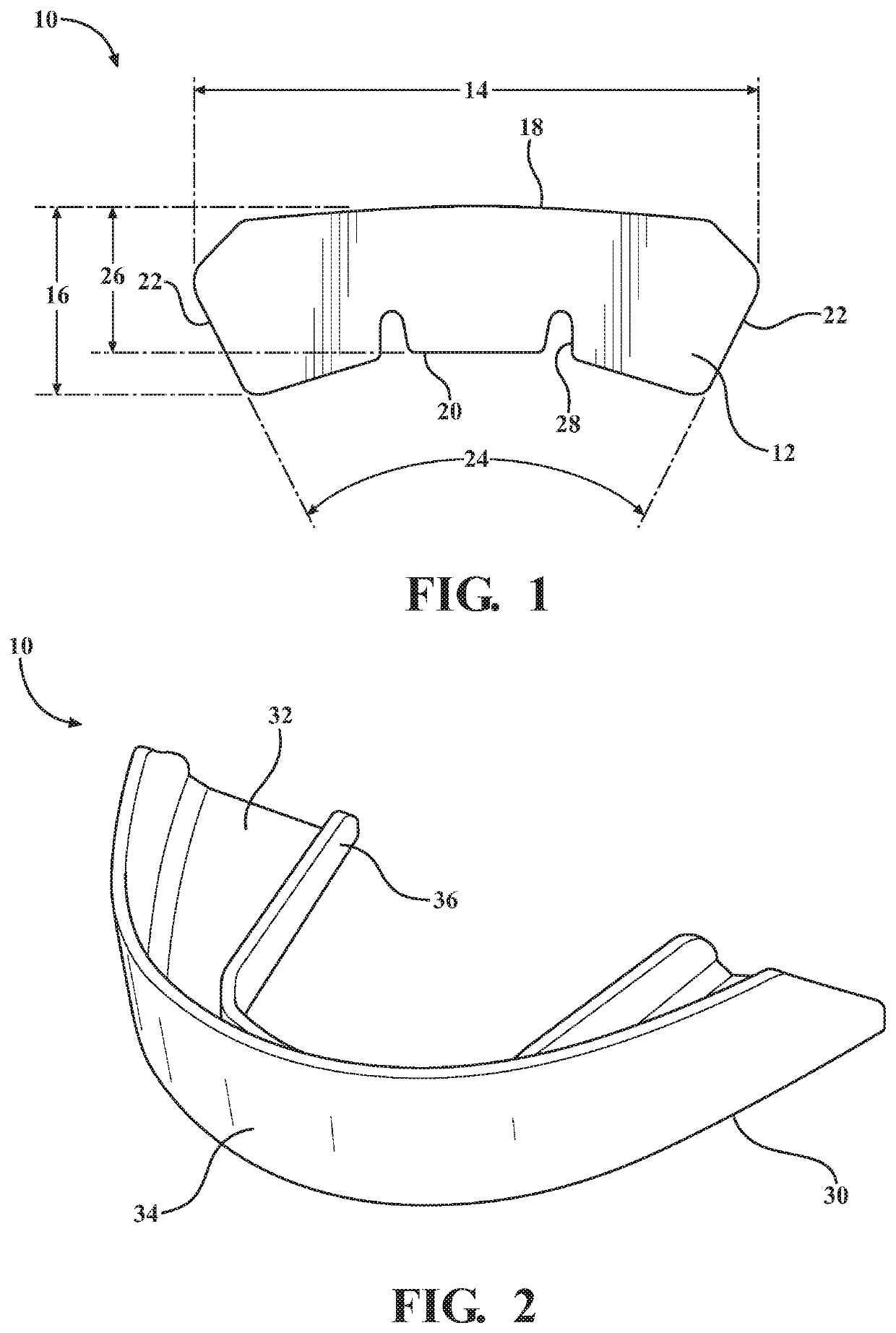

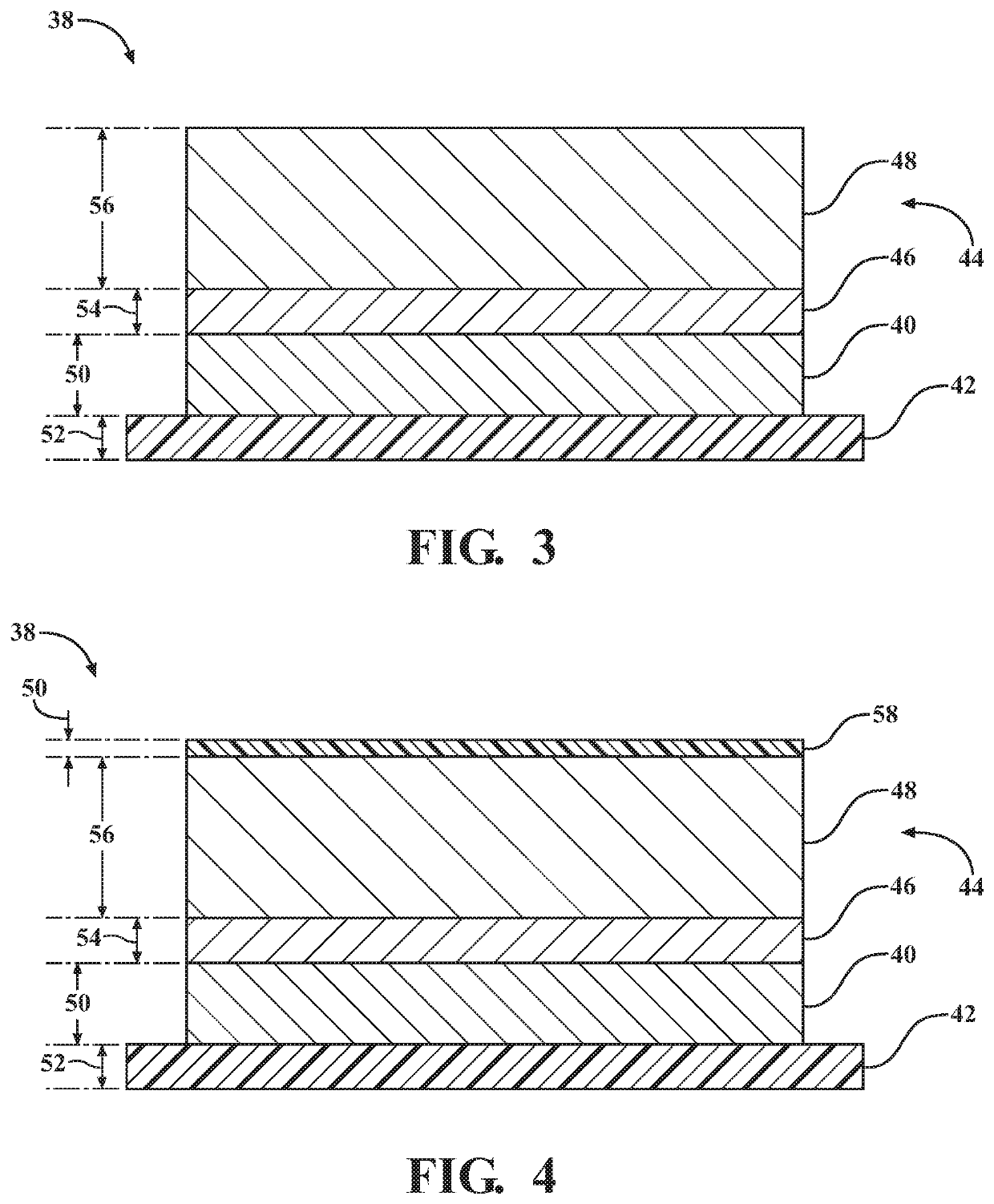

Oral care composition and devices formed therewith

An oral care composition is disclosed. The oral care composition includes (A) an adhesive agent comprising an alkylated polyvinylpyrrolidone, (B) a miscibility component comprising an acrylic acid-acrylate copolymer, and (C) a plasticizer comprising a polyalkylene glycol. An oral care device is also disclosed. The oral care device includes an oral care layer comprising the oral care composition and a whitening agent. A method of preparing the oral care device is also disclosed, and includes extruding the oral care composition to give the oral care layer, and preparing a laminate comprising the oral care layer. The method may further include processing the laminate to give the oral care device, which may be prepared as an oral care strip or an oral care tray.

Owner:RANIR LLC

Oral care compositions with film forming polymers

ActiveUS10092482B2Low costImprove convenienceCosmetic preparationsToilet preparationsAcetic acidAlcohol

Oral care compositions comprising:a) an oral care active; andb) an acrylic film forming polymer.In various embodiments, such polymers comprise monomeric units such as acrylic acid, methacrylic acid, acrylates, and combinations thereof. In one embodiment, the film forming polymer comprises a copolymer of a first monomeric unit selected from the group consisting of acrylic acid, methacrylic acid, and combinations thereof, with a second monomeric unit selected from the group consisting of acrylates, acrylamides, acetates, and combinations thereof. In various embodiments, the polymer is a terpolymer comprising a combination of the second monomeric units. Preferably, the composition additionally comprises a lower alcohol, such as ethanol. In various embodiments, the oral care active comprises a whitening material, such as a peroxide.

Owner:COLGATE PALMOLIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com