Core-shell structure nanoparticle and preparation method of hardened water-based acrylic resin coating

A technology of water-based acrylic and core-shell structure, applied in the direction of coating, etc., can solve the problems of unstable resin performance in the polymerization process, lack of storage stability, cumbersome process, etc., achieve excellent weather resistance and light transmittance, and improve dispersion stability , good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for core-shell structure nanoparticles, characterized in that, comprising the following steps:

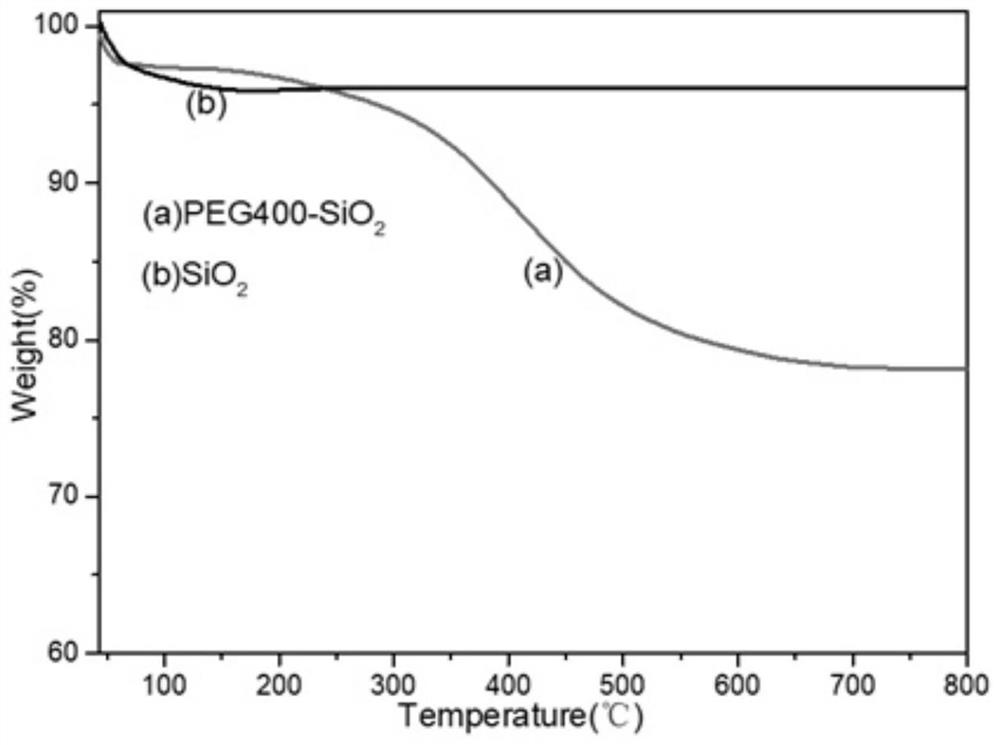

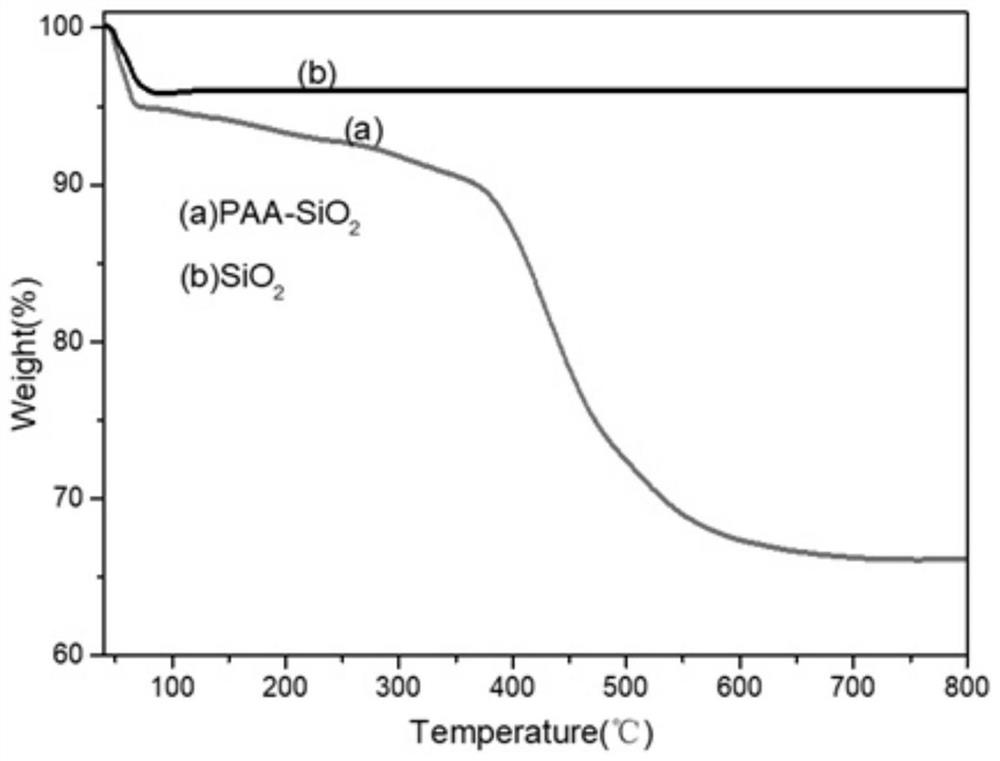

[0039] S1, put 1 ~ 5g nano-SiO 2 Add 150-300ml of organic solvent, ultrasonically disperse for 1 hour, put the mixture into a three-necked flask equipped with a condenser, an electric stirrer and a thermometer, raise the temperature to 40-80% ℃, and control the stirring rate at 300-600r / min After stirring for 1-2 hours, add 1-5ml of silane coupling agent, and after reacting for 6-12 hours, filter the solution to obtain nano-SiO modified by silane coupling agent. 2 Precipitate, after washing, vacuum drying and grinding, the modified nano-SiO 2 particle;

[0040] S2. Take 1-5g of nano-SiO modified by silane coupling agent in step 1). 2 Added to a condensing tube, an electric stirrer and a thermometer while feeding N 2 In a four-necked flask, heat up to 60-100% °C, and control the stirring rate at 200-600r / min. After stirring for 1-2 hours, add polymer ...

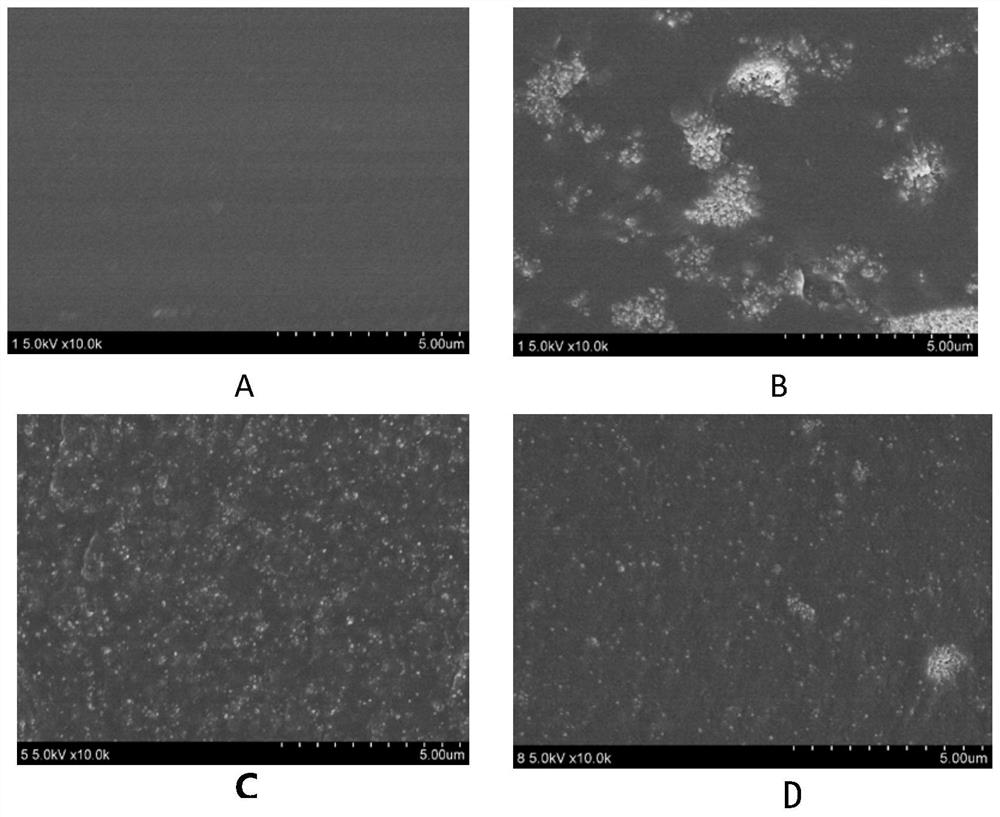

Embodiment 1

[0062] 1g nano-SiO 2 and 200ml of toluene solvent into a three-necked flask equipped with a condenser, an electric stirrer and a thermometer. After ultrasonic dispersion for 1h, the flask was heated in an oil bath, and the temperature was raised to 70°C. The stirring rate was controlled at 400r / min, and stirred for 2 Hour. Add 1ml of silane coupling agent isocyanate propyltriethoxysilane and 5ml of deionized water into a four-necked flask equipped with a condenser tube, an electric stirrer and a thermometer while feeding N2, and raise the temperature to 70°C , the stirring rate was controlled at 300r / min, and the reaction was carried out for 8 hours to obtain a solution modified by the silane coupling agent. Afterwards, 1 ml of deionized water and acetic acid were added to the obtained solution to adjust the pH to 3, and the solution was ultrasonically oscillated for 1 hour. Add the hydrolyzed silane coupling agent to the SiO 2 In a three-necked flask, the reaction was conti...

Embodiment 2

[0076] Weigh 1.0g of SiO 2 Add it into a three-necked flask, add 150ml of toluene solution, stir at a speed of 300 rpm, and heat in an oil bath at 75°C for 0.5h. At the same time, weigh 1.0g of silane coupling agent γ-(methacryloyloxy)propyltrimethoxy and 1.0g of deionized water into the sample bottle, drop acetic acid to adjust the pH to about 3, put the sample bottle Ultrasonic hydrolysis in an ultrasonic water bath for 1 h. Then the hydrolyzed silane coupling agent was added into the three-necked flask, and the rotation speed was raised to 500 rpm for 6 hours of reaction. After the reaction, the mixture was suction-filtered to obtain a white powder solid, which was washed three times with ethanol solution, dried in an oven at 50°C for 24 hours, and then taken out for use.

[0077] 1g modified nano-SiO 2and 180ml of toluene solvent into a three-necked flask equipped with a condenser, an electric stirrer and a thermometer. After ultrasonic dispersion for 1h, the flask was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com