A kind of laundry pod and preparation method thereof

A technology of washing beads and fat, which is applied in the direction of chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problem that the decontamination effect and antibacterial performance need to be further improved, the decontamination effect is not ideal, and the decontamination effect is not ideal. The problem of poor bacterial performance and other problems can be achieved, and the effect of high-efficiency synergistic decontamination, stability and vitality can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

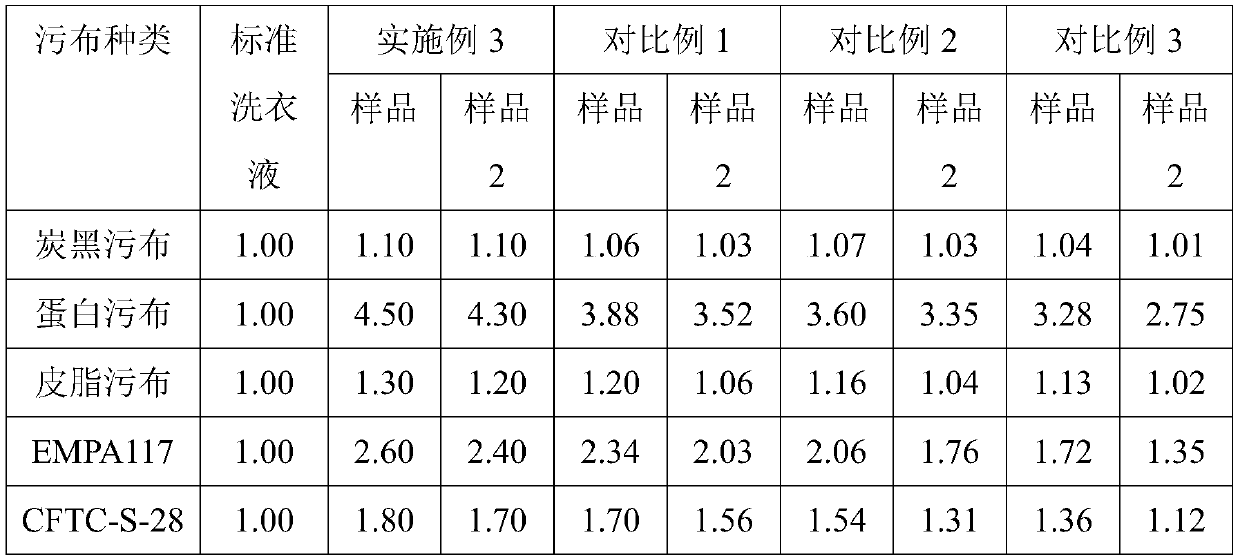

Examples

Embodiment 1

[0041] Embodiment 1, a kind of laundry beads

[0042] The laundry beads are composed of the following components and their mass percentages: fatty alcohol polyoxyethylene ether 30%, glycerin 10%, propylene glycol 15%, potassium laurate 10%, fatty acid methyl ester ethoxylate 12%, deionized Water 5.195%, acrylic acid-acrylate copolymer 5%, organosilicon compound 5%, flavor 5%, compound enzyme 0.8%, microcapsule flavor 0.6%, silver ion compound 0.5%, glutamic acid N,N-acetoacetate tetra Sodium 0.5%, preservative 0.2%, pigment 0.005%, citric acid 0.2%; the fatty alcohol polyoxyethylene ether is composed of fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 9) Formed by mass ratio of 20:30; the composite enzyme is composed of the inclusion compound of protease, lipase, amylase and cellulase by mass ratio of 7:7:4:2; the preservative is composed of 5-chlorine -2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one ar...

Embodiment 2

[0050] Embodiment 2, a kind of laundry beads

[0051] The laundry beads are composed of the following components and their mass percentages: fatty alcohol polyoxyethylene ether 63%, glycerin 5%, propylene glycol 10%, potassium laurate 8%, fatty acid methyl ester ethoxylate 5%, deionized Water 5.439%, acrylic acid-acrylate copolymer 1%, organosilicon compound 1%, flavor 1%, compound enzyme 0.2%, microcapsule flavor 0.1%, silver ion compound 0.1%, glutamic acid N,N-acetoacetate tetra Sodium 0.1%, preservative 0.01%, pigment 0.001%, citric acid 0.05%; the fatty alcohol polyoxyethylene ether is composed of fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 9) Formed by mass ratio of 45:10; the composite enzyme is composed of the inclusion compound of protease, lipase, amylase and cellulase by mass ratio of 10:5:2:1; the preservative is composed of 5-chlorine -2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one ar...

Embodiment 3

[0056] Embodiment 3, a kind of laundry beads

[0057] The laundry beads are composed of the following components and their mass percentages: fatty alcohol polyoxyethylene ether 46%, glycerin 6%, propylene glycol 10%, potassium laurate 10%, fatty acid methyl ester ethoxylate 10%, deionized Water 8.418%, acrylic acid-acrylate copolymer 2%, organosilicon compound 3%, flavor 3%, compound enzyme 0.4%, microcapsule flavor 0.4%, silver ion compound 0.3%, glutamic acid N,N-acetoacetate tetra Sodium 0.3%, preservative 0.08%, pigment 0.002%, citric acid 0.1%; the fatty alcohol polyoxyethylene ether is composed of fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 9) Formed by mass ratio of 21:25; the composite enzyme is composed of the inclusion compound of protease, lipase, amylase and cellulase by mass ratio of 9:6:3:1; the preservative is composed of 5-chlorine -2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com