Shrinkage-reducing polycarboxylic acid type superplasticize, preparation method and application thereof

A technology of superplasticizer and polycarboxylic acid series, which is applied in the field of preparation of shrinkage-reducing polycarboxylate series superplasticizer, can solve the problems of environmental pollution, non-compliance with environmental protection and energy saving modernization development, energy waste, etc., and achieve the preparation process Simple, excellent air-entraining effect, good enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

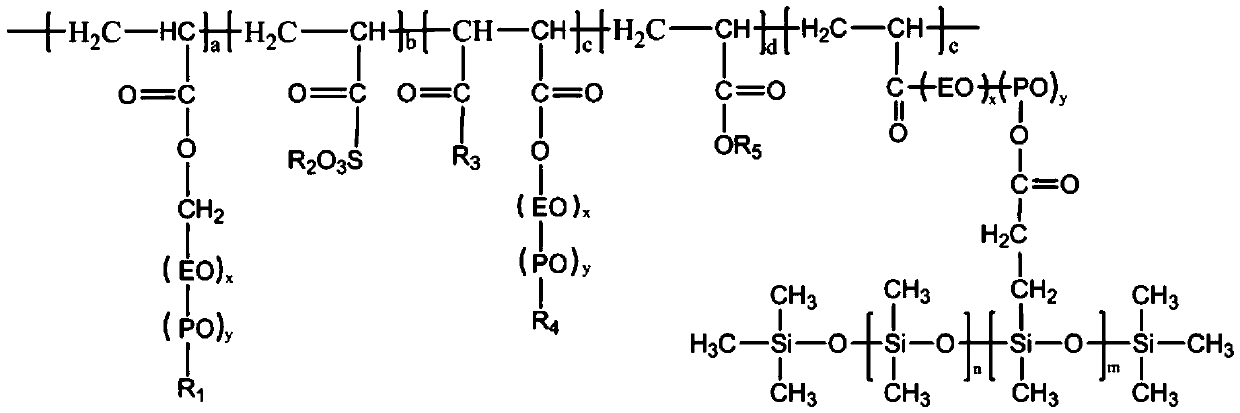

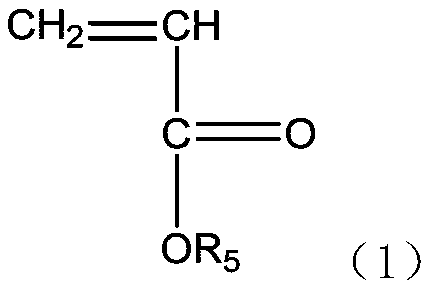

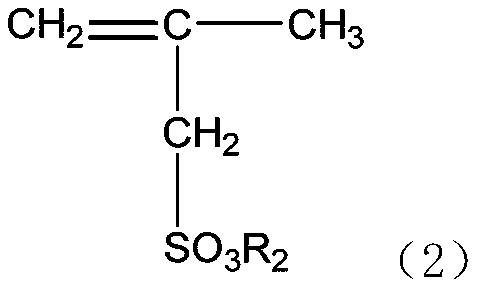

[0079] The preparation method of monomer C: the esterification reaction occurs directly by acrylic acid and the following (4) polyether at a molar ratio of 1:1.0 to 4.5 under solvent-free conditions, and under the conditions of adding a polymerization inhibitor and a catalyst;

[0080]

[0081] In formula (4), x and y are integers from 0 to 50 respectively, and R 1 It is an alkyl or hydroxyl group with 1 to 5 carbon atoms; EO represents ethylene oxide units, PO represents propylene oxide units, which can be linear or branched polymers, homopolymers, block copolymers, etc. These polyether groups are grafted into the copolymer to provide a certain dispersion ability and water retention performance, and at the same time provide a certain steric hindrance ability.

[0082] The aforementioned catalysts can be concentrated sulfuric acid, p-toluenesulfonic acid, phosphorous acid and solid superacids, etc. Lewis acids such as boron trifluoride, aluminum trichloride and iron sulfate...

Embodiment 1

[0110] Embodiment 1: superplasticizer preparation process

[0111] Monomer C preparation process:

[0112] In a 500ml glass reactor equipped with a thermometer, a stirrer, a nitrogen inlet tube and a reflux condenser, under the condition of no solvent, add an appropriate amount of polyether (the following formula, wherein x=23, y=0, R 1 is hydroxyl), the temperature is raised to 50°C, and after the polyether is completely melted, add acrylic acid (the molar ratio of acrylic acid to polyether is 3:1), polymerization inhibitor (hydroquinone, and hydroquinone accounts for 2% of the total mass of acrylic acid) and catalyst (concentrated sulfuric acid, and concentrated sulfuric acid accounts for 1.0% of the total mass of polyether), gradually warming up to 80-85 ° C and continuous reaction for 5h to obtain the crude product of monomer C, which can be directly Used in the synthesis of shrinkage-reducing polycarboxylate superplasticizers;

[0113]

[0114] Monomer D preparation ...

Embodiment 2

[0122] Embodiment 2: the concrete that mixes superplasticizer

[0123] The superplasticizer used in this example is the superplasticizer prepared in Example 1. Calculate the mass according to the solids in the superplasticizer:

[0124] In terms of mass percentage, cement 15.119%, sand 35.067%, 5-10mm pebbles 17.135%, 10-20mm pebbles 25.702%, water 6.929%, superplasticizer 0.048%; according to SL352-2006 "Hydraulic Concrete Test Regulations" Methods Coordinated mixing (slump controlled at 21±1cm), placed on a vibrating table and vibrated for 30s before forming, plastered before the initial setting of the concrete, removed the formwork after 24 hours, and sent it to the curing room for standard curing.

[0125] According to GB8076-2008 "Concrete Admixture" specification, the plasticizer meets the requirements of standard high-performance water reducer, and its performance indicators all meet the requirements of the specification. When the amount of superplasticizer is 0.32% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com