Green and environment-friendly composite scale and corrosion inhibition chemical and preparation method thereof

A scale and corrosion inhibiting, green and environmentally friendly technology, applied in chemical instruments and methods, complex/solubilizing agent treatment, scale removal and water softening, etc., can solve the problems of increased cost of chemicals, water pollution, etc., and achieve low cost and easy Biodegradable, high tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

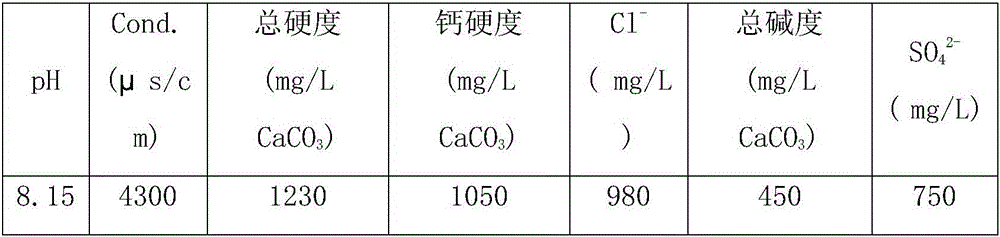

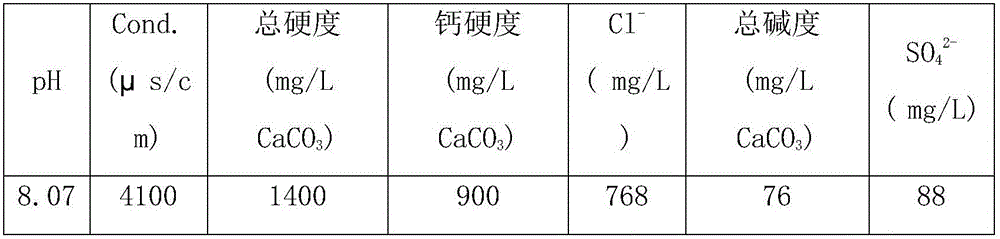

Image

Examples

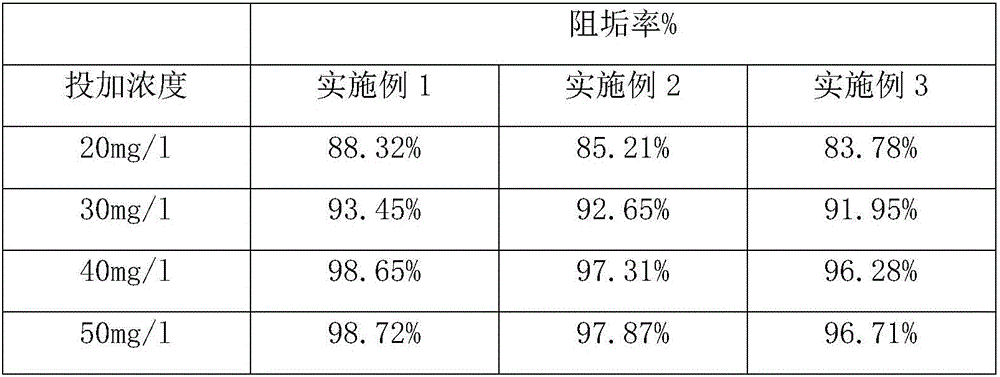

Embodiment 1

[0031] Composite antiscaling and corrosion inhibitor, the weight of each component is as follows: 15 parts of polyamino polyether group methylene phosphonic acid, 20 parts of polyol phosphate, 12 parts of polyepoxy succinic acid, acrylic acid-acrylic acid ester-sulfonate 13 parts of copolymer, 6 parts of anhydrous zinc chloride, 5 parts of co-solvent, 29 parts of water. The preparation process is carried out according to the above-mentioned preparation method to obtain the composite anti-scaling and slow-release agent of the present invention.

[0032] The preparation method of the compound scale and corrosion inhibitor in this example is as follows:

[0033] 1) According to the above component distribution ratio, add polyamino polyether group methylene phosphonic acid, polyol phosphate and 1 / 2 water into the reaction kettle and mix, heat to 40°C, adjust the speed to 110r / min, and stir for 15min , to obtain solution A;

[0034] 2) Add polyepoxysuccinic acid, acrylic acid-acr...

Embodiment 2

[0038] In the composite scale and corrosion inhibitor of the present invention, the parts by weight of each component are as follows: 18 parts of polyaminopolyether-based methylene phosphonic acid, 22 parts of polyol phosphate, 8 parts of polyepoxysuccinic acid, acrylic acid-acrylic acid 15 parts of ester-sulfonate copolymer, 5 parts of anhydrous zinc chloride, 4 parts of co-solvent, 28 parts of water. The preparation process is carried out according to the above-mentioned preparation method to obtain the composite anti-scaling and slow-release agent of the present invention.

[0039] The preparation method of the compound scale and corrosion inhibitor in this example is as follows:

[0040] 1) According to the above component distribution ratio, add polyamino polyether group methylene phosphonic acid, polyol phosphate and 1 / 2 water into the reaction kettle and mix, heat to 40°C, adjust the speed to 120r / min, and stir for 20min , to obtain solution A;

[0041] 2) Add polyepo...

Embodiment 3

[0045] In the composite scale and corrosion inhibitor of the present invention, the parts by weight of each component are as follows: 12 parts of polyamino polyether group methylene phosphonic acid, 18 parts of polyol phosphate, 10 parts of polyepoxysuccinic acid, acrylic acid-acrylic acid 17 parts of ester-sulfonate copolymer, 6 parts of anhydrous zinc chloride, 5 parts of co-solvent, 32 parts of water. The preparation process is carried out according to the above-mentioned preparation method to obtain the composite anti-scaling and slow-release agent of the present invention.

[0046] 1) According to the above component distribution ratio, add polyaminopolyether group methylene phosphonic acid, polyol phosphate and 1 / 2 water into the reaction kettle and mix, heat to 40°C, adjust the speed to 110r / min, and stir for 20min , to obtain solution A;

[0047] 2) Add polyepoxysuccinic acid, acrylic acid-acrylic acid ester-sulfonate copolymer and remaining water into the reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com