Foam fire extinguishing agent for automotive ethanol gasoline fire

A technology of foam fire extinguishing agent and ethanol for vehicles, which is applied in fire prevention equipment, etc., can solve problems such as poor fire extinguishing performance, unsatisfactory fire extinguishing effect, insufficient continuous and tight gel film, etc., to enhance strength and toughness, and improve fire extinguishing The effect of strong ability and anti-resurgence ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

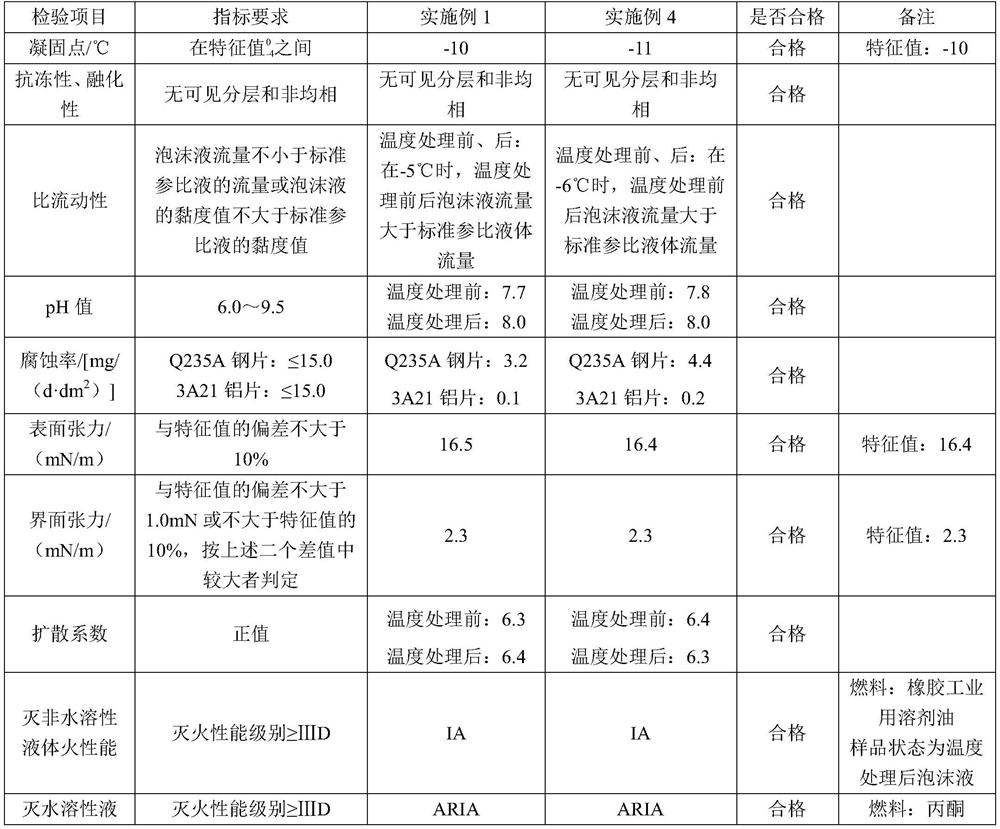

Examples

Embodiment 1

[0027] In the present embodiment, the film-forming agent of ethanol gasoline fire foam fire extinguishing agent for vehicles is xanthan gum, the film aid is acrylic acid-maleic anhydride copolymer, the foaming agent is lauryl amidopropyl betaine, and the fluorosurfactant is Capstone 1470, the cosolvent is ethylene glycol monobutyl ether, the antifreeze is glycerol, and the preservative is sodium benzoate. Each raw material is film-forming agent and film-aiding agent according to mass percentage, and the total is 2%, wherein film-forming agent: film-aiding agent=1:4, blowing agent is 5%, fluorosurfactant is 4%, and co-solvent is 10% %, antifreeze is 10%, preservative is 0.3%, and the rest is water.

[0028] The preparation process is as follows: add 20kg of water to the first stirred tank, then add 0.4kg of film-forming agent and 1.6kg of film-aiding agent, stir until the mixture is uniform to obtain a mixture of film-forming agent and film-aiding agent; Add 48.7kg of water to...

Embodiment 2

[0031] In the present embodiment, the vehicle ethanol gasoline fire foam fire extinguishing agent film-forming agent is xanthan gum, the film-aiding agent is acrylic acid-acrylate copolymer, the foaming agent is sodium lauryl polyoxyethylene ether sulfate, and the fluorosurfactant is Forafac 1203G, cosolvent is diethylene glycol butyl ether, antifreeze is glycerol, preservative is sodium benzoate. Each raw material is 2.5% of film-forming agent and film-aiding agent according to mass percentage, wherein film-forming agent: film-aiding agent=1:4, foaming agent is 5%, fluorosurfactant is 7%, and co-solvent is 15% , Antifreeze is 10%, preservative is 0.3%, and the rest is water.

[0032] The preparation process is as follows: add 20kg of water to the first stirred tank, then add 0.5kg of film-forming agent and 2.0kg of film-aiding agent, stir until the mixture is uniform to obtain a mixture of film-forming agent and film-aiding agent; Add 40.2kg of water to the kettle, heat and ...

Embodiment 3

[0035] In the present embodiment, the vehicle ethanol gasoline fire foam fire extinguishing agent film-forming agent is xanthan gum, the film-aiding agent is acrylic acid-acrylic acid ester copolymer, the blowing agent is alkyl glucoside, the fluorosurfactant is Capstone 1475, and the cosolvent is Propylene glycol methyl ether, antifreeze agent is ethylene glycol, preservative is sodium benzoate. Each raw material is 3% of film-forming agent and film-aiding agent according to mass percentage, wherein film-forming agent: film-aiding agent=1:2, foaming agent is 8%, fluorosurfactant is 7%, and co-solvent is 12% , Antifreeze is 15%, preservative is 0.5%, and the rest is water.

[0036] The preparation process is as follows: add 20 kg of water to the first stirred tank, then add 1 kg of film-forming agent and 2 kg of film-aiding agent, stir and mix evenly to obtain a mixed solution of film-forming agent and film-aiding agent; then add to the second stirred tank 44.5kg of water, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com