Millimeter wave single-channel control TR assembly

A single-channel, millimeter-wave technology, used in radio wave measurement systems, instruments, etc., can solve problems such as difficulty in meeting requirements, and achieve the effect of saving production costs, good electromagnetic compatibility performance, and saving design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

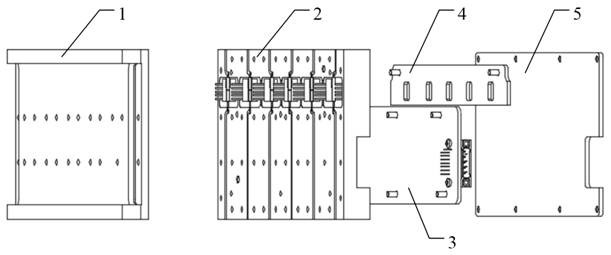

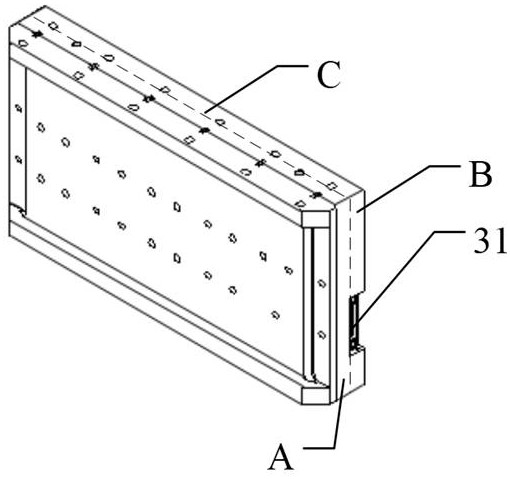

[0031] A millimeter-wave single-channel control TR component, see the attached Figure 1-7 , the TR component includes a component body, and the component body includes an upper side A and a lower side B. The upper side A and the lower side B are two parts divided by the component body from the middle part C. It should be noted that the " The middle part C" can be the middle of the component body, or other non-edge positions, as long as the electronic components in the upper side A and the electronic components in the lower side B can be isolated. Several groups of radio frequency structures are set on the upper side A of the component body, and the adjacent radio frequency structures are isolated from each other. The mutual isolation can be realized by setting metal plates, for example, to increase the isolation between channels. Each group of radio frequency structures includes a TR chip 21 , a VM chip 22 and a transmission line structure bonded to each other with gold wires...

Embodiment 2

[0035] This embodiment discloses the structure of the component body.

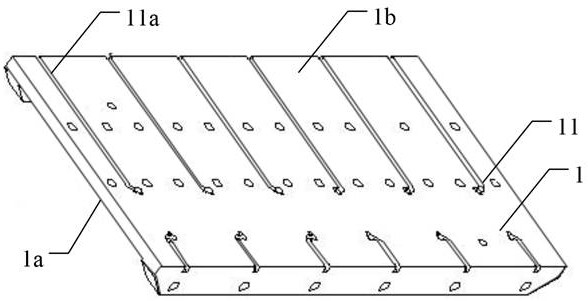

[0036] The component body includes an upper cavity 1 and a lower cavity 2, such as figure 1 ,3 , 4, the upper cavity 1 includes the upper surface 1a of the upper cavity and the lower surface 1b of the upper cavity, the upper surface 1a of the upper cavity and the lower surface 1b of the upper cavity are opposite; the lower cavity 2 includes The upper surface 2a of the lower cavity is opposite to the lower surface 2b of the lower cavity, and the upper surface 2a of the lower cavity is opposite to the lower surface 2b of the lower cavity. The lower surface 1b of the upper cavity is docked with the upper surface 2a of the lower cavity and connected together by screws, and the position is located on the upper side A of the component body. The transmission line structure is arranged between the lower surface 1b of the upper cavity and the upper surface 2a of the lower cavity. The VM chips 22 and TR chips 21 o...

Embodiment 3

[0040] This embodiment takes the design of 6 channels as an example (the number of other channels is designed in the same way), and discloses a W-band single-channel control TR component, such as Figure 1-7 As shown, the upper cavity 1 and the lower cavity 2 are included, the upper cavity 1 includes the upper surface 1a of the upper cavity and the lower surface 1b of the upper cavity, the upper surface 1a of the upper cavity and the lower surface 1b of the upper cavity Relatively; the lower cavity 2 includes an upper surface 2a of the lower cavity and a lower surface 2b of the lower cavity, and the upper surface 2a of the lower cavity is opposite to the lower surface 2b of the lower cavity. The lower surface 1b of the upper cavity is docked with the upper surface 2a of the lower cavity and connected together by screws.

[0041] Six sets of first waveguide structures 11a are arranged on the lower surface 1b of the upper cavity, and each first waveguide structure 11a constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com