Pectinate flexible variable-damping rubber plate and processing method thereof

A rubber plate and variable damping technology, which is applied in the field of sound insulation and noise reduction plates and comb-shaped flexible variable damping rubber plates, can solve the problems of poor vibration damping effect and space layout, and achieve the effects of strong applicability, low installation time and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below according to specific embodiment and accompanying drawing, specific structure and processing method of the present invention are described in detail:

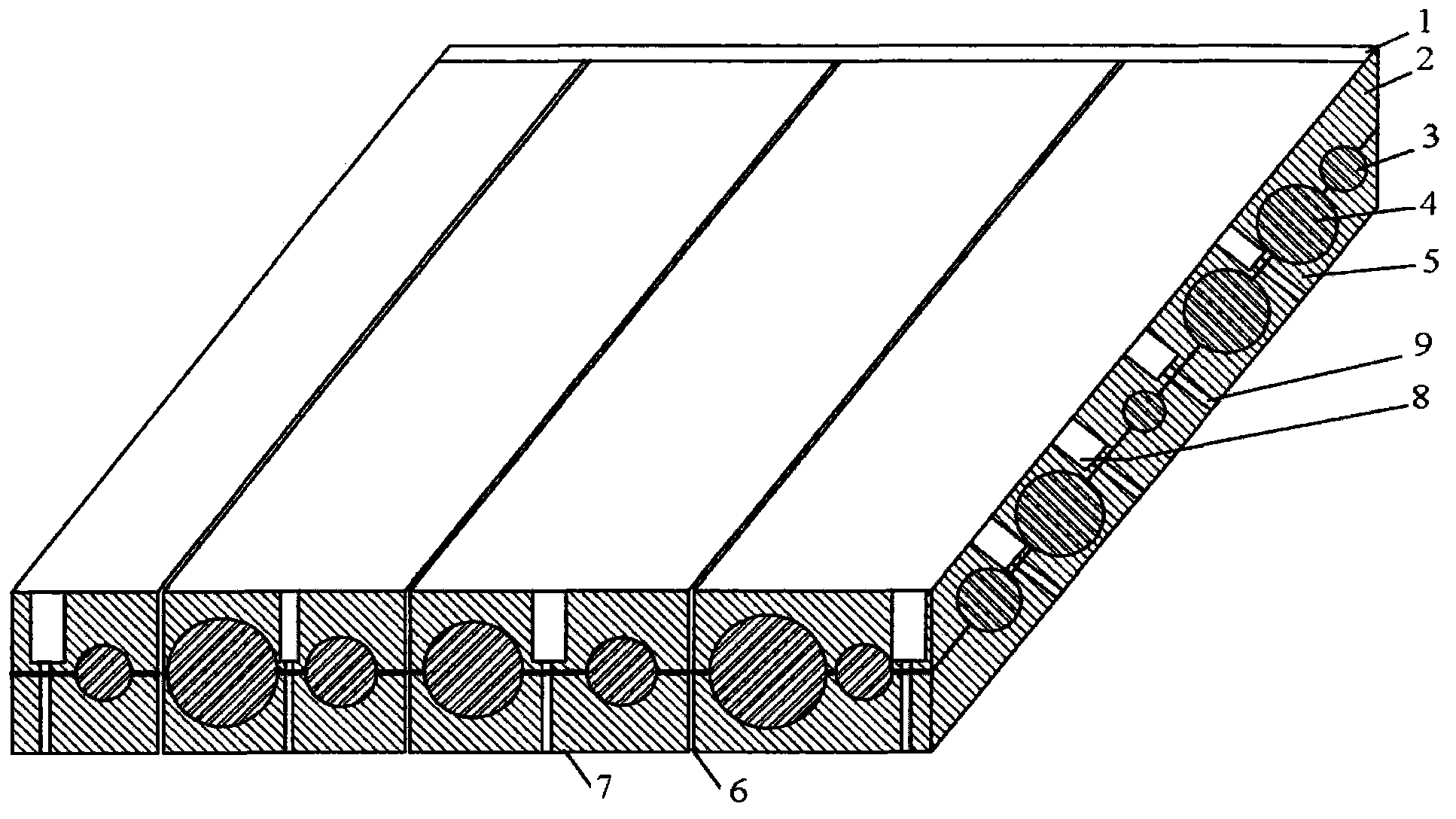

[0018] Such as figure 1 As shown, a comb-shaped flexible variable damping rubber plate structure is composed of a plurality of rubber comb-shaped plate strips 7 connected together, and the distance between two adjacent rubber comb-shaped plate strips 7 is 10mm, thus forming a comb shape structure.

[0019] Each rubber comb-shaped plate strip 7 is composed of an upper rubber plate 2, a lower rubber plate 5, a sound-absorbing hole, and a plurality of small-diameter stainless steel balls 3 and a plurality of large-diameter stainless steel balls 4 arranged in the middle of the two layers of rubber plates. Steel balls of different diameters are arranged at different positions of the rubber comb-shaped plate strip 7. The steel balls are set without quantity limitation, determined by the actual length of the plate, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com