Multi-trunking petroleum pipe structure

A technology for oil pipes and trunking, which is applied to drill pipes, casings, drilling equipment, etc., can solve the problems of unreasonable setting of trunking, poor thermal insulation effect, short service life, etc., so as to reduce maintenance costs and prolong service life. , to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

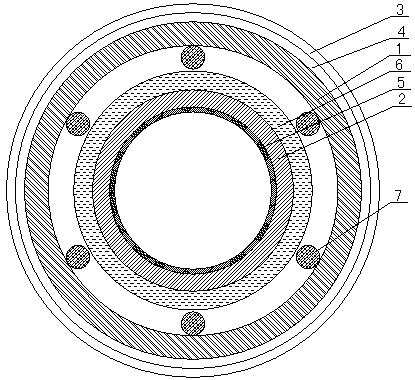

[0011] Such as figure 1 As shown, the multi-slot oil pipe structure according to the embodiment of the present invention includes an outer pipe body 1 and an inner pipe body 2. The inner pipe body 2 is disposed at the center of the inner cavity of the outer pipe body 1 and the inner pipe body 2 is provided with a layer of anti-corrosion layer 5 on the inner surface, and at the same time, a layer of glass wool heat preservation and heat insulation layer 6 is provided on the outer surface of the inner tube body 2. It is important to mention that the outer surface of the outer tube body 1 is covered with FRP protective shell 4 and a plastic protective film layer 3 is arranged on the outer layer of the FRP protective shell 4. In addition, six leakage alarm lines with protective shells are evenly arranged in the cavity between the inner tube body 2 and the outer tube body 1. 7. The thickness of the FRP protective shell 4 and the plastic protective film layer 3 are both 2.5cm, 4cm or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com