Method and device for preventing irrigation electronic control valve from being out of operation

A technology of working failure and electric control valve, which is applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of small control channel aperture, poor reliability, incomplete emptying of water, etc., and achieve fast switching control Agility, improve work reliability and work stability, improve the effect of water inlet and discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

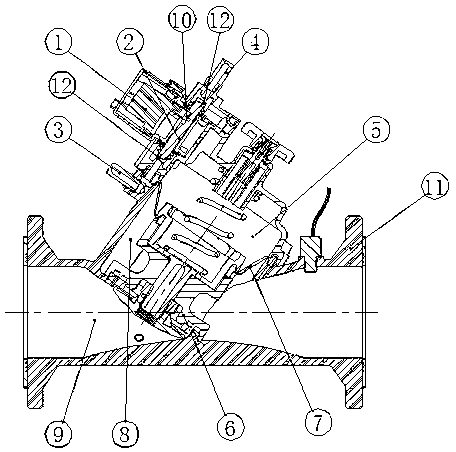

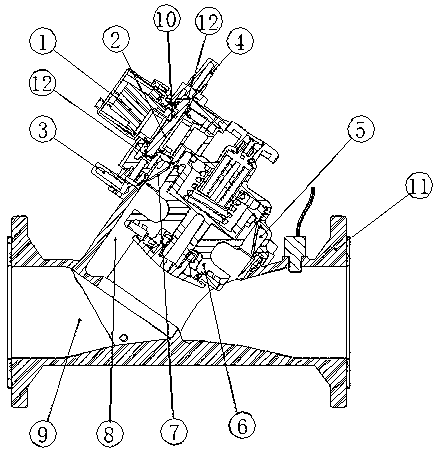

[0016] A method to prevent the failure of the electric control valve for irrigation, such as figure 1 and figure 2 shown. In this method, the water passage 9 in the electric control valve is isolated from the upper cavity 5 through the elastic cup 7 arranged between the valve core assembly 6 and the valve cavity, and the upper cavity 5 is connected to the control channel; at the same time, the pilot diaphragm 12. Isolate the entire control mechanism from the waterway to prevent the impact of sediment and impurities on the movement of the control mechanism; to improve the reliability of the electric control valve. The control channel adopts a larger aperture of 6-8mm to reduce the blockage of the control channel by silt or impurities; at the same time, the silt or impurity deposition in the cavity is reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com