Novel single-hole carbonization chamber pressure regulating system and regulating method

An adjustment system and single-hole carbon technology, which is applied in the coking field, can solve the problems of complex structure of the single-hole carbonization chamber pressure adjustment system, and achieve the effects of simple structure, high adjustment sensitivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

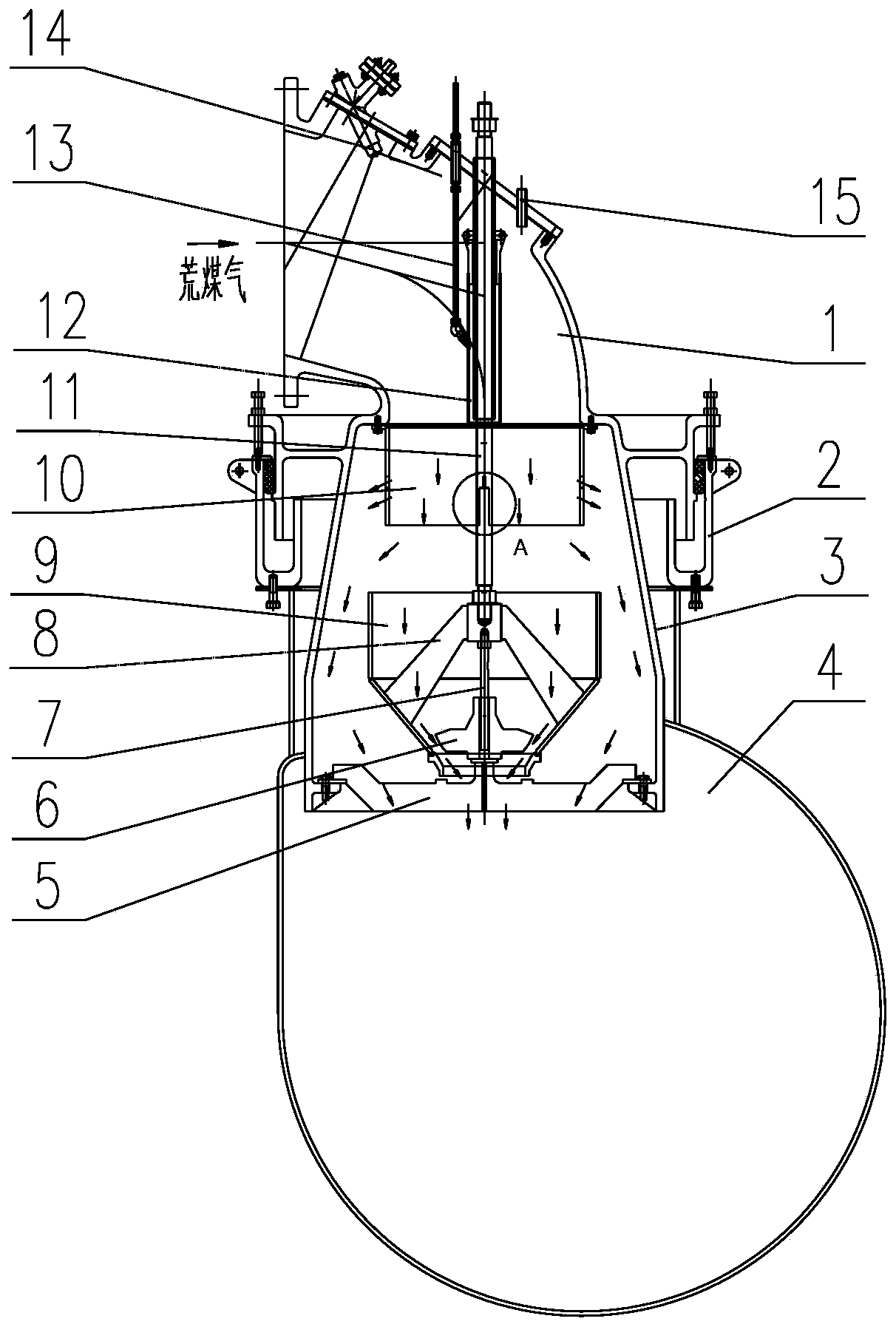

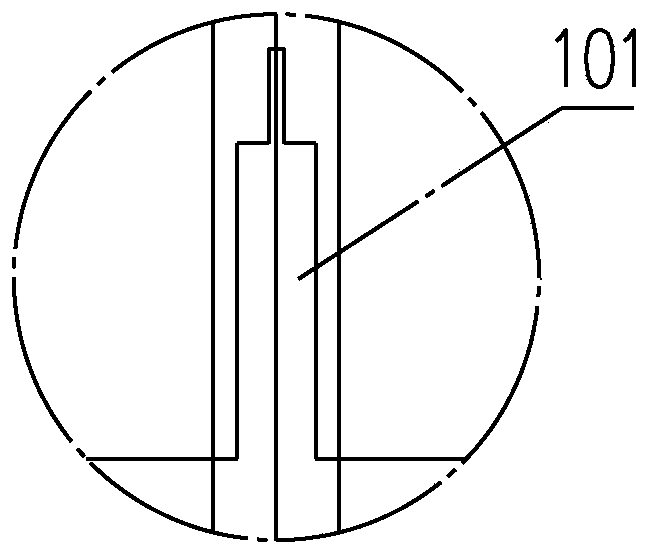

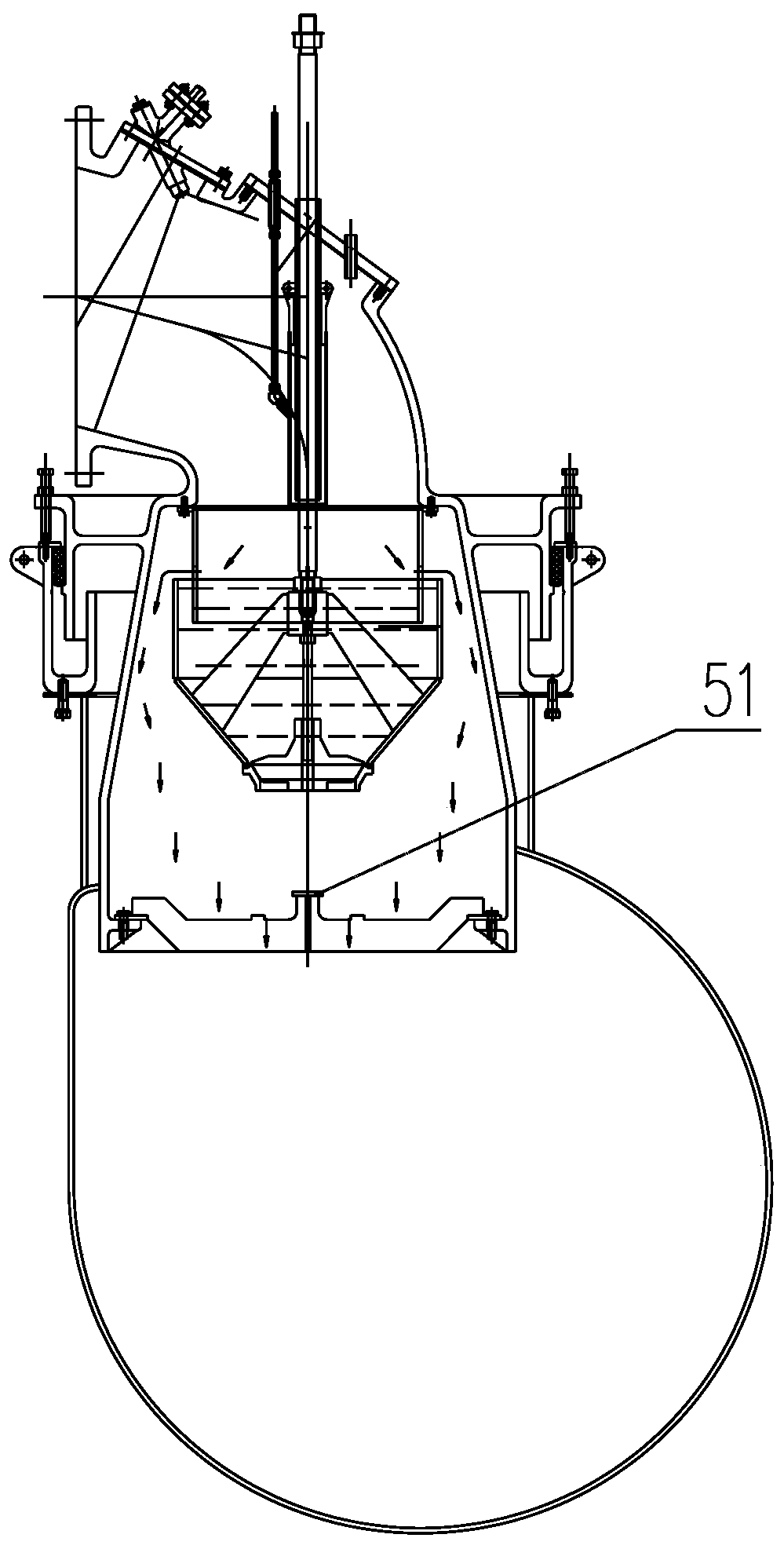

[0030] Such as figure 1 , image 3 , Figure 4 As shown, a novel single-hole carbonization chamber pressure regulating system of the present invention includes a pressure regulating device installed between the bridge pipe 1 and the gas collecting pipe 4; the bottom end of the bridge pipe 1 is provided with an expansion pipe 3 to The top of the pipe 3 is connected to the bridge pipe 1, and the bottom end extends into the air collecting pipe 4, and the outside of the expanding pipe 3 is connected with the air collecting pipe 4 through the water seal seat 2; the inside of the expanding pipe 3 is provided with a pressure regulating device; The pressure device includes a fixed ring 10, a moving cup 9, a cylinder, a cylinder rod 11, a cross beam 5, an ammonia water nozzle 14 and a pressure measuring device 15; directly below; the bridge pipe 1 above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com