Multi-shaft support air floatation platform leveling method

An air-floating platform and shaft support technology, which is applied in the directions of supporting machines, machine tables/brackets, and feedback control, etc., and can solve the problems of narrow application scope and limited leveling state of supporting platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

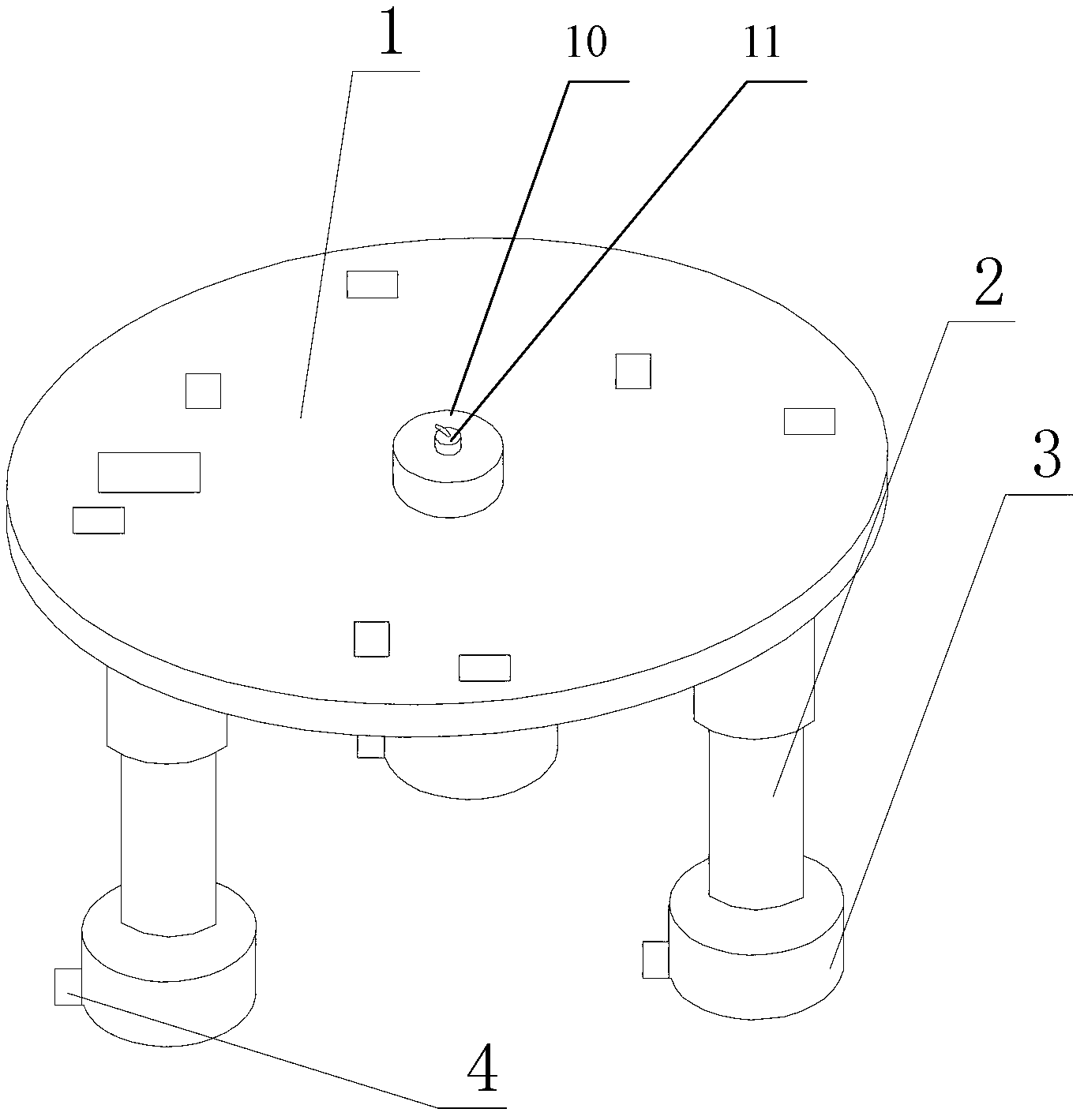

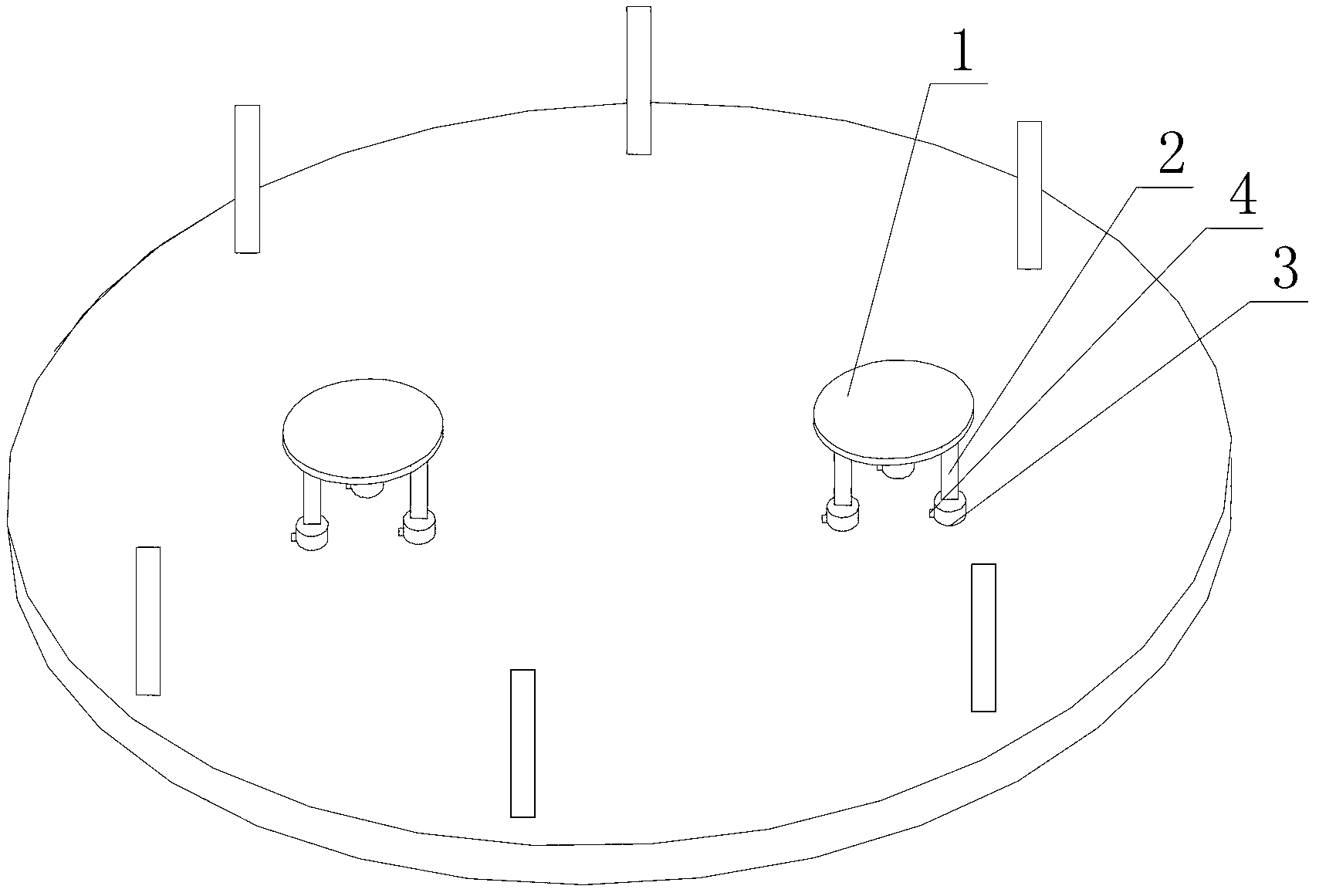

[0071] Specific implementation mode 1: the following combination Figure 1 to Figure 10 In this embodiment, the leveling method of the multi-axis support air floating platform in this embodiment will be described. The multi-axis support air floating platform includes a bearing platform 1, M supporting legs 2, M air floats 3, and M air feet. 4, M is 3, 4, 5, 6, 7 or 8,

[0072] The carrying platform 1 is a circular platform, the carrying platform 1 is supported by M supporting legs 2, and M connecting points between the M supporting legs 2 and the lower surface of the carrying platform 1 form a regular M polygon;

[0073] The end of each support leg 2 is connected with an air float 3, and the bottom end of each air float 3 is connected with an air foot 4 through an air float ball bearing;

[0074] The leveling method realizes leveling through a measurement control system of a multi-axis supporting air-floating platform. The measurement control system includes a load feedback unit 5, a...

specific Embodiment approach 2

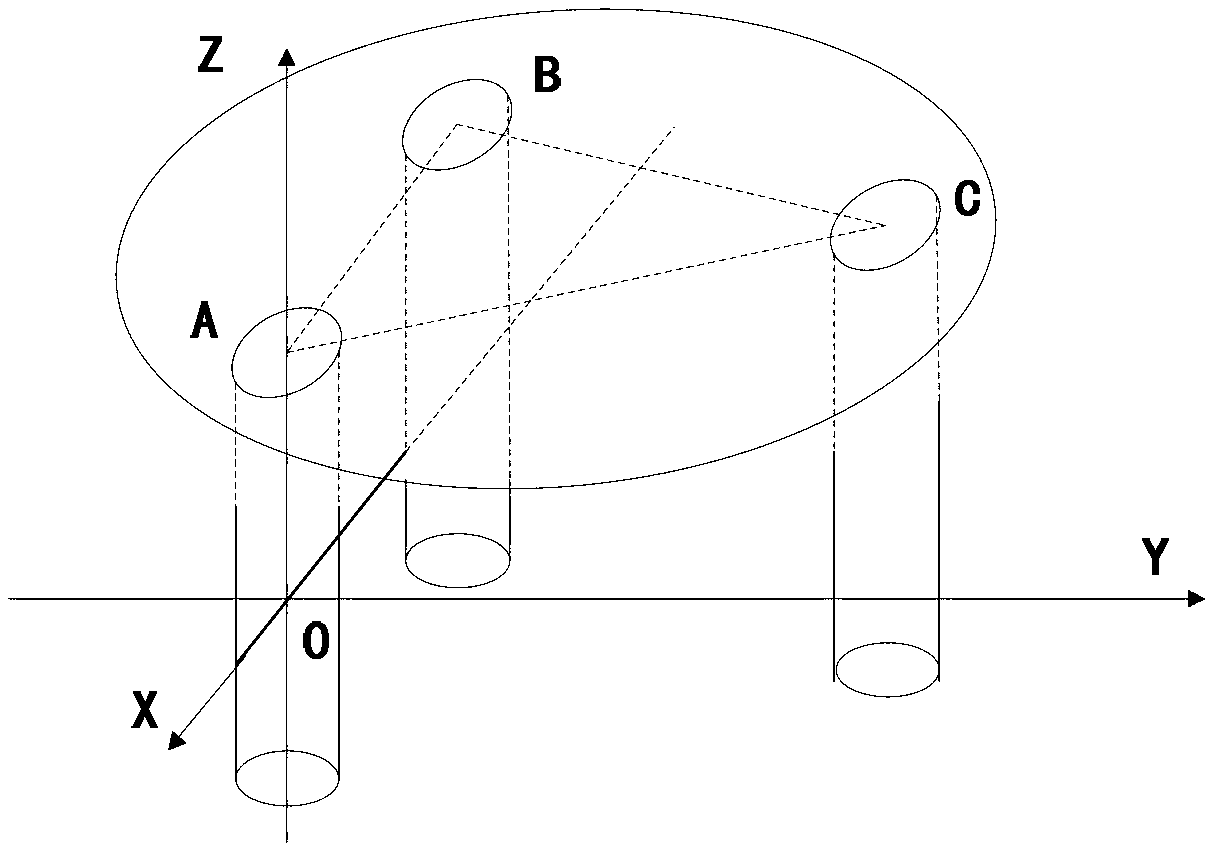

[0101] Specific implementation manner 2: the following combination Picture 8 This embodiment will be described. This embodiment will further explain the first embodiment. In this embodiment, M is 3, and the controller 9 in step 6 and step 7 performs data fusion processing on all the feedback signals it reads to obtain The specific method of adjusting the amount of support leg 2 is:

[0102] Set the linear array CCD7-3 to consist of six CCDs. The six CCDs on the circular horizontal concrete base are numbered in the circumferential direction as ①, ②, ③, ④, ⑤ and ⑥, with No. ④ CCD and No. ① The center line of the CCD is used as the X-axis direction of the spatial rectangular coordinate system, which is located on the horizontal plane X-0-Y where the reference light of the linear light source 11 is located, and the Y-axis of the spatial rectangular coordinate system is defined according to the right-hand rule Direction and Z-axis direction, set the radius of the circular horizontal ...

specific Embodiment approach 3

[0122] Specific implementation manner 3: the following combination Figure 1 to Figure 10 This embodiment will be described. This embodiment will further explain the first or second embodiment. The radius of the carrying platform 1 in this embodiment is 2 meters, and the three supporting legs are equilateral formed by three connection points on the lower surface of the carrying platform 1 The distance between the vertex of the triangle and the center of the bearing platform 1 is 1.4 meters.

[0123] image 3 As shown, the support leg 2 of the multi-axis supporting air bearing platform and the three connection points A, B, and C on the lower surface of the bearing platform 1 form an equilateral triangle with a side length of L=2424 mm. The air foot 4 relies on compressed air to form an air film between the air float ball bearing and the ball sleeve to achieve a nearly frictionless motion to simulate the dynamic environment of the spacecraft in the outer space with extremely small d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com