Subaperture jointing laser interference on-line measuring method and subaperture jointing laser interference on-line measuring system based on intelligent digital control platform

A technology of sub-aperture splicing and numerical control platform, which is used in measuring devices, optical devices, instruments, etc., can solve the problems of large volume, self-weight, optical surface processing and measurement difficulties, etc., and achieves strong spatial movement and positioning capabilities, and lightweight structure. , The effect of saving equipment cost

Inactive Publication Date: 2013-09-11

FUDAN UNIV

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the processing and measurement of this type of optical surface is much more difficult than that of plane and spherical surfaces, especially the measurement of large-aperture and high-steep aspheric surfaces has become the focus and difficulty of current research at home and abroad.

In addition, due to the large size and weight of large-diameter plane mirrors and spherical mirrors, the detection problem in processing has also become one of the bottlenecks restricting processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

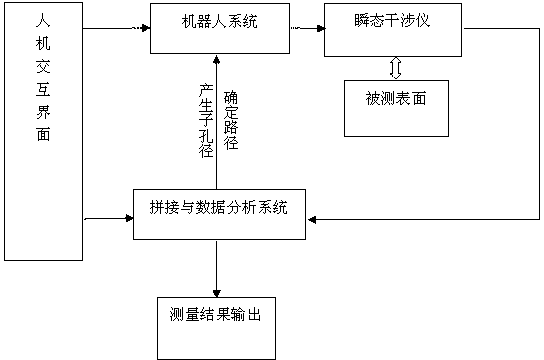

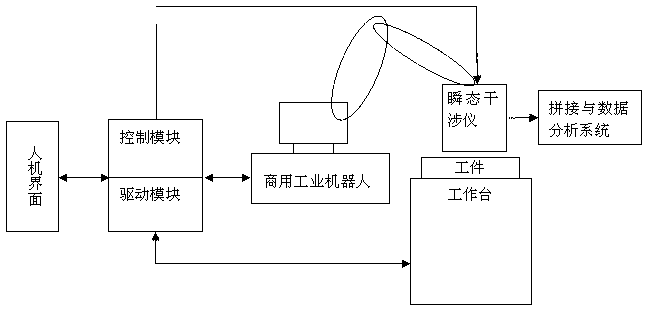

[0036] Such as figure 2 Shown is the block diagram of the entire online measurement system. figure 1 Work flow chart for the entire online measurement system.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

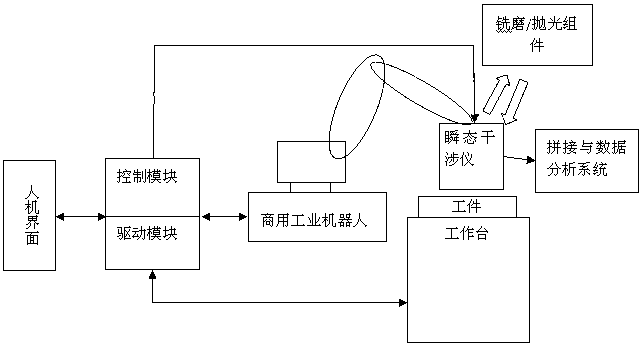

The invention belongs to the field of the modern optical measurement technology, and particularly relates to a subaperture jointing laser interference on-line measuring method and a subaperture jointing laser interference on-line measuring system based on an intelligent digital control platform. The subaperture jointing laser interference on-line measuring system comprises an industrial robot and control modules thereof, a driving module, a transient interferometer, a jointing and data analyzing system, a human-computer interaction interface and a workbench. Originally, the industrial robot performs polishing on optical elements through polishing components mounted on the wrist portion of the industrial robot. The transient interferometer is mounted on the wrist portion of the industrial robot through a flange according to the standard the same as a polishing head, so that precision measurement can be performed on each subaperture surface shape of a workpiece surface, and the jointing and data analyzing system is utilized to measure the surface shape of the overall workpiece surface. The subaperture jointing laser interference on-line measuring method and the subaperture jointing laser interference on-line measuring system based on the intelligent digital control platform are low in production cost, good in commonality and convenience, and can measure various kinds of surface shapes on line.

Description

Technical field [0001] The invention belongs to the field of modern optical measurement technology, and specifically relates to a computer-controlled (CNC)-based online measurement system and method for subaperture splicing laser transient interference, especially for large-aperture aspheric surfaces and flat, spherical, and complex surface optics In-situ online measurement during parts polishing. Background technique [0002] Subaperture Stitching Interferometry (SSI) is a comprehensive technology that combines optical interference, precision machinery, computer image processing, and mathematical analysis. The sub-aperture stitching interferometry method makes up for the shortcomings of the traditional full-aperture interferometry method with limited aperture and surface shape. The transient interferometer uses the pixelated four-phase mask technology to overcome the shortcomings of the traditional interferometer collecting and measuring data, and has a good anti-interference a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/24G01B9/02

Inventor 王伟徐敏

Owner FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com