Device and method for measuring microscopic topography of workpiece surface coated with cutting fluid

A microscopic topography and workpiece surface technology, applied in the direction of measuring devices, optical devices, instruments, etc., to avoid surface cutting fluid residue, simple optical path of the device, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

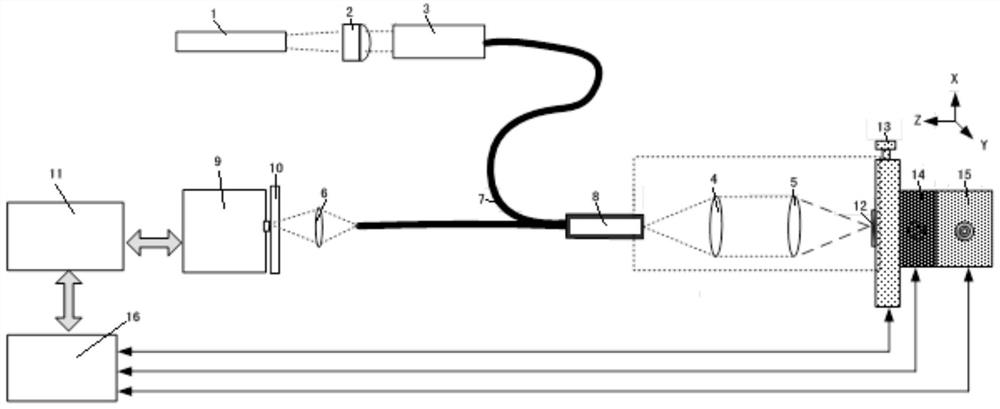

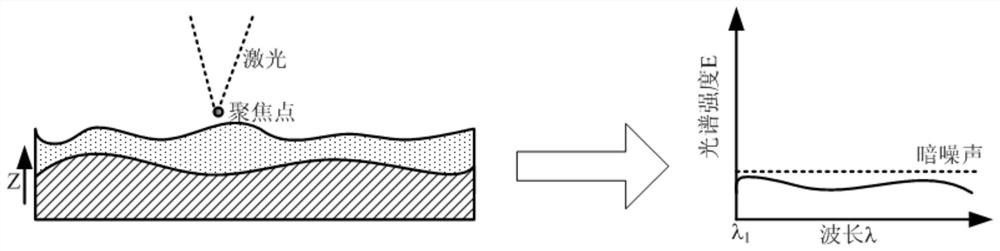

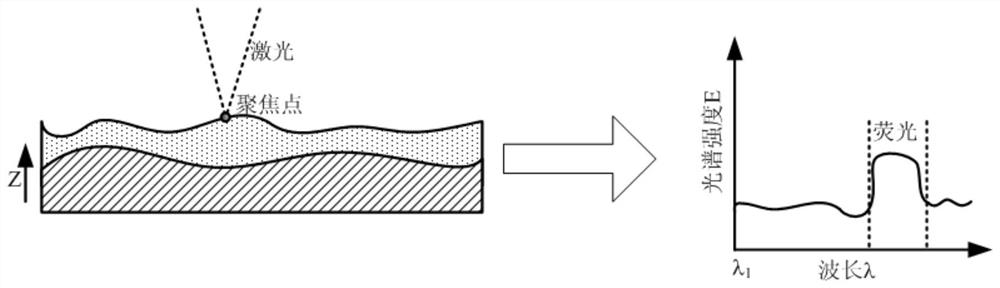

[0035] A workpiece surface microtopography measuring device coated with cutting fluid, such as figure 1 As shown, it consists of laser 1, collimating lens 2, laser coupler 3, lens I4, lens II5, lens III6, Y-shaped fiber 7, fiber coupler 8, spectrometer 9, long-pass filter 10, computer 11, and X-axis The motion table 13, the Y-axis motion table 14, the Z-axis motion table 15, and the motion controller 16 are composed. The laser 1 is collimated by the collimator lens 2, coupled into the Y-shaped optical fiber 7 by the laser coupler 3, outputs the laser light through the fiber coupler 8, and then focuses on the workpiece sample through the optical fiber confocal optical path composed of lens 4 and lens 5 Surface; the cutting fluid on the surface of the sample is excited by the laser to generate fluorescence, and the scattered fluorescence returns to the Y-shaped optical fiber 7 through the confocal optical path of the optical fiber, and is focused by the lens 6. After the laser w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com