A method and device for on-line measurement of three-dimensional shape of icing

A measurement method and shape technology, applied in measurement devices, optical devices, image analysis, etc., can solve the problems of low measurement accuracy, low reflectivity of bright ice, and diffusion of the laser band in the collected image, and achieve high measurement accuracy and image quality. Clear, high-contrast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

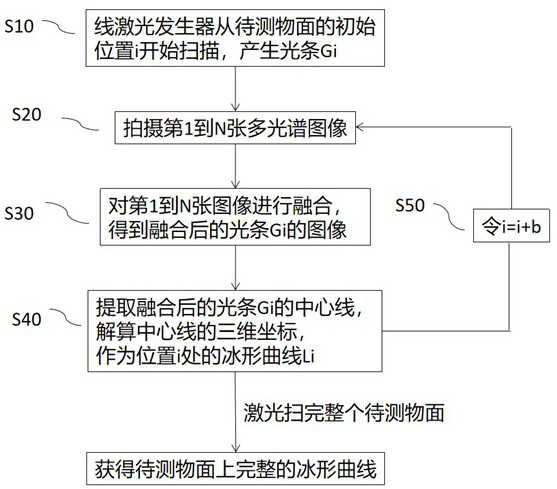

[0039] An on-line measurement method of icing three-dimensional shape, such as figure 1 and figure 2 shown, including the following steps:

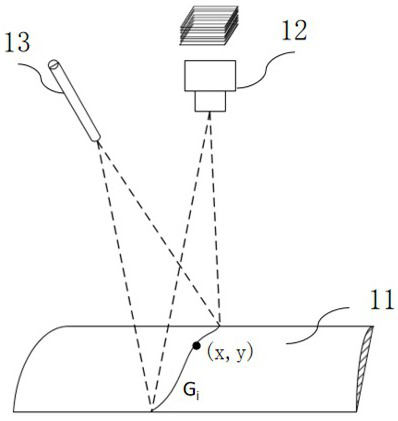

[0040] S10. The line laser generator 13 starts scanning from the initial position i of the object surface to be measured, and the line laser generator projects a light plane to the object surface 11 to be measured, and intersects the surface of the object to be measured to generate a light bar G i ; Among them, i is any position on the surface of the object to be measured;

[0041] That is to say, the line laser generator can start scanning from any position on the surface of the object to be measured, and in the subsequent step S50, the line laser generator is rotated until the entire surface of the object to be measured is swept, and then the ice scanning of one section ends. ;

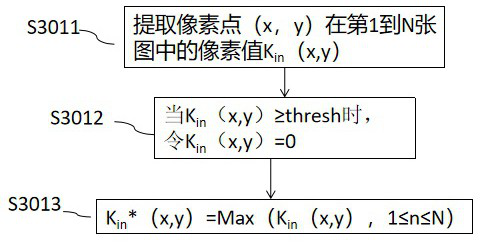

[0042] S20. Multispectral camera 12 simultaneous shooting light bar G i , forming a target for the light bar G iThe first to N images of reflected light ...

Embodiment 2

[0064] This embodiment provides a measurement device for completing the measurement method of Embodiment 1, such as Figure 4 shown, including a multispectral image acquisition system and a data processing system (not shown in the figure);

[0065] The multispectral image acquisition system includes a multispectral camera 12, a rotating table (not shown in the figure) and a line laser generator 13; the line laser generator is arranged on the rotating table; when in use, the multispectral camera 12 and the line laser generator 13 are arranged facing the object surface 11 to be measured; it is worth noting that there is no specific limitation on the positional relationship between the multispectral camera and the line laser generator, as long as the line laser generator and the multispectral camera are There is no mutual interference, and the line laser generator can project the laser to the surface of the object to be measured, and the multispectral camera can capture the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com