Plant leaf surface humidity sensor and plant leaf surface humidity measurement device

A technology of humidity sensor and surface humidity, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate simulated leaf surface humidity value, difficult to quantitatively describe plant leaves, etc., achieve convenient and accurate data support, and improve sensing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment describes a plant leaf surface humidity sensor, including a substrate and a flexible copper strip;

[0040] The substrate is a flexible glass fiber board;

[0041] The flexible copper strip supports the flexible glass fiber board, and divides the flexible glass fiber board into a humidity sensing unit and a frequency sensing unit;

[0042] The humidity sensing unit is located on the left side of the humidity sensor, and the top of the flexible glass fiber board is the lower leaf-like pattern gold-plated copper grid, cellulose acetate polymer material, the upper leaf-like pattern gold-plated copper grid and the surface layer Optical latex coating;

[0043]The cellulose acetate polymer material forms two electrodes with the gold-plated copper grid with imitation leaf pattern and the gold-plated copper grid with the lower imitation leaf pattern respectively; the two electrodes are respectively connected with the surface optical latex coating It is bonded ...

Embodiment 2

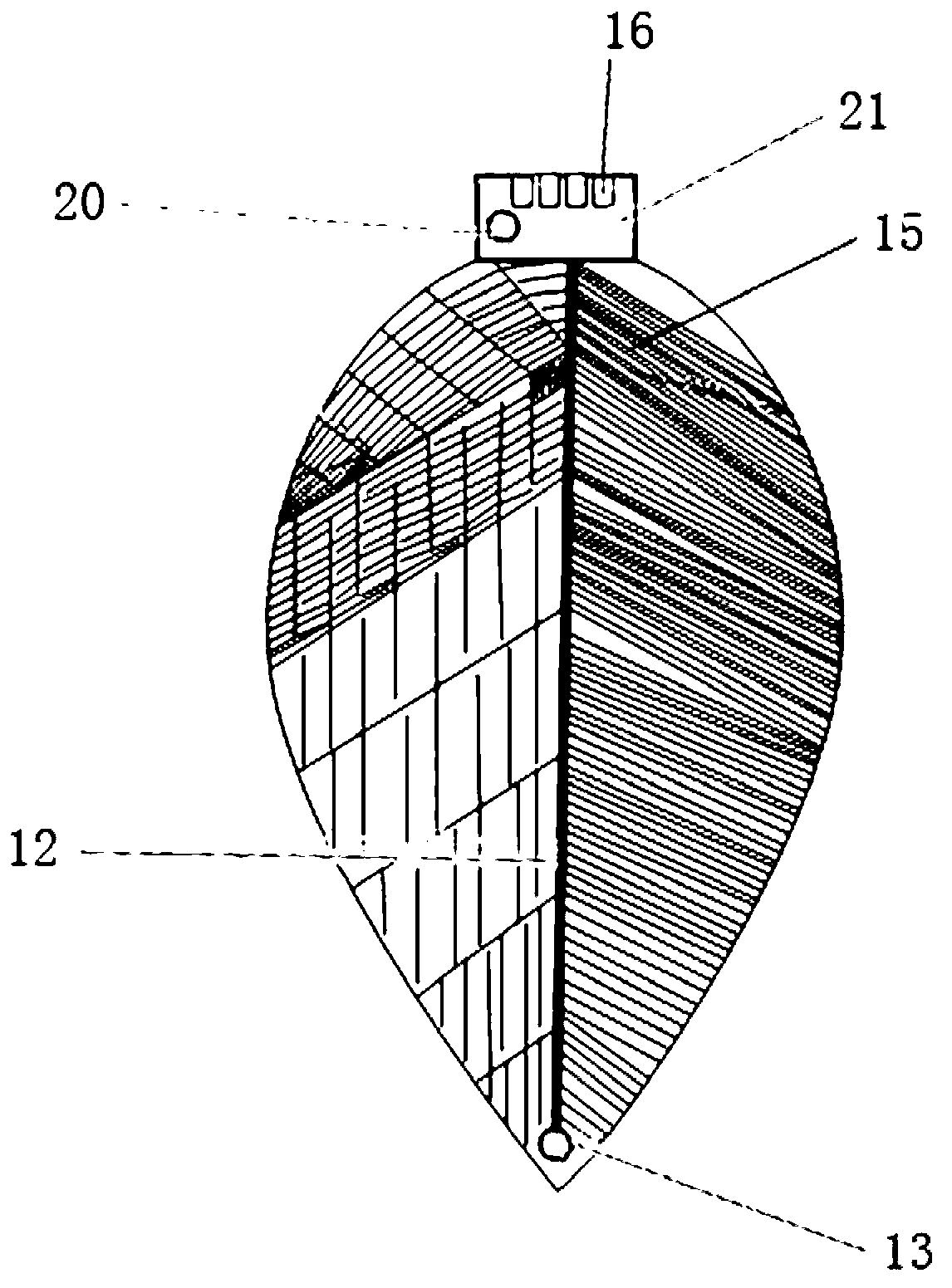

[0046] Such as figure 1 As shown, this embodiment describes a plant blade surface humidity sensor, including: flexible glass fiber board 17 , flexible copper strip 12 , blade bending angle adjustment hole 13 and fixed sealing block 21 . The flexible glass fiber plate 17 is used as the substrate of the simulated blade, and the flexible copper strip 12 is 1 mm, supporting the flexible glass fiber plate 17 and dividing the flexible glass fiber plate 17 into a humidity sensing unit on the left and a frequency sensing unit on the right.

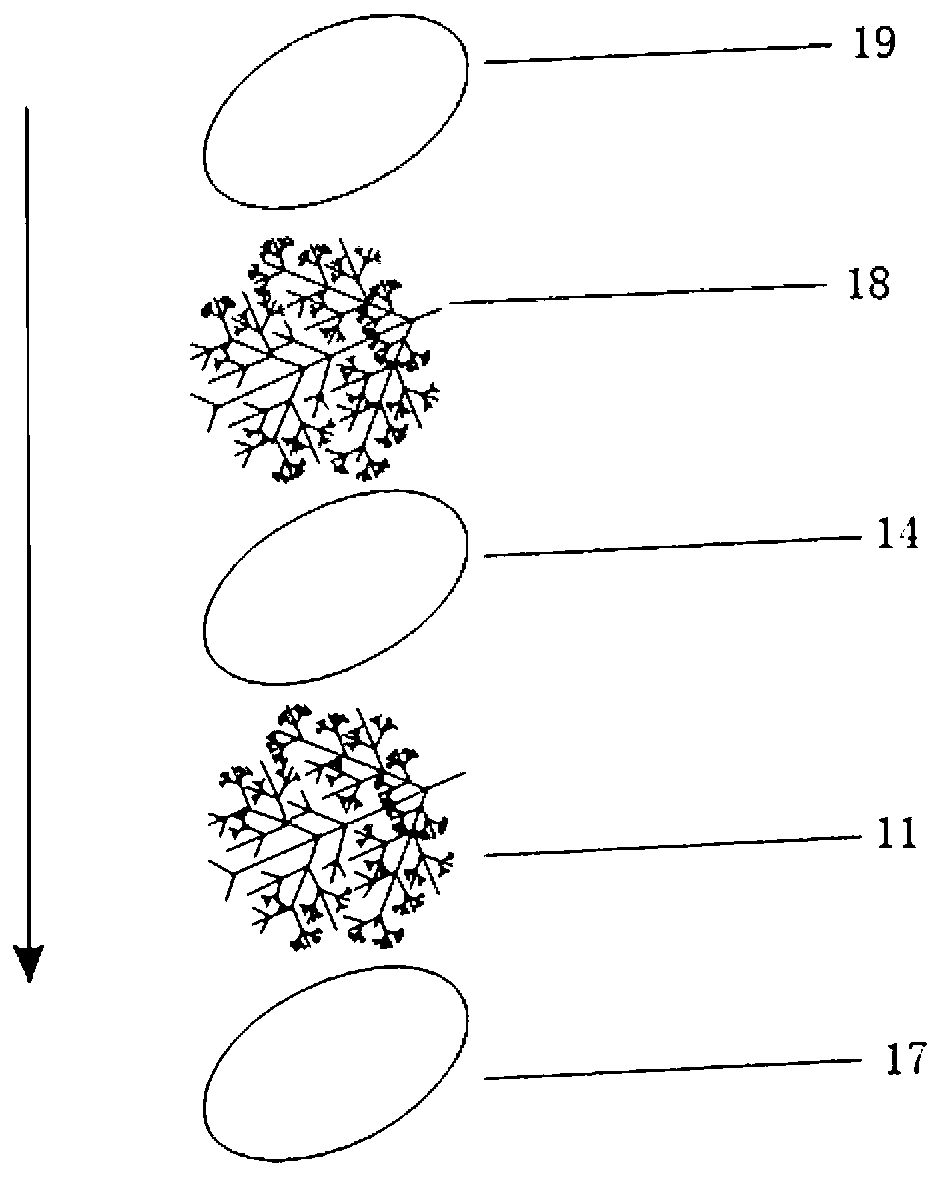

[0047] The structure of the humidity sensing unit on the left is as follows figure 2 As shown, on the top of the flexible glass fiber board are the lower leaf-like pattern gold-plated copper grid 18 , acetate polymer material 14 , the upper leaf-like pattern gold-plated copper grid 11 and the surface optical latex coating 19 . The cellulose acetate polymer material 14 is used to form two electrodes respectively with the upper gold-plated copper ...

Embodiment 3

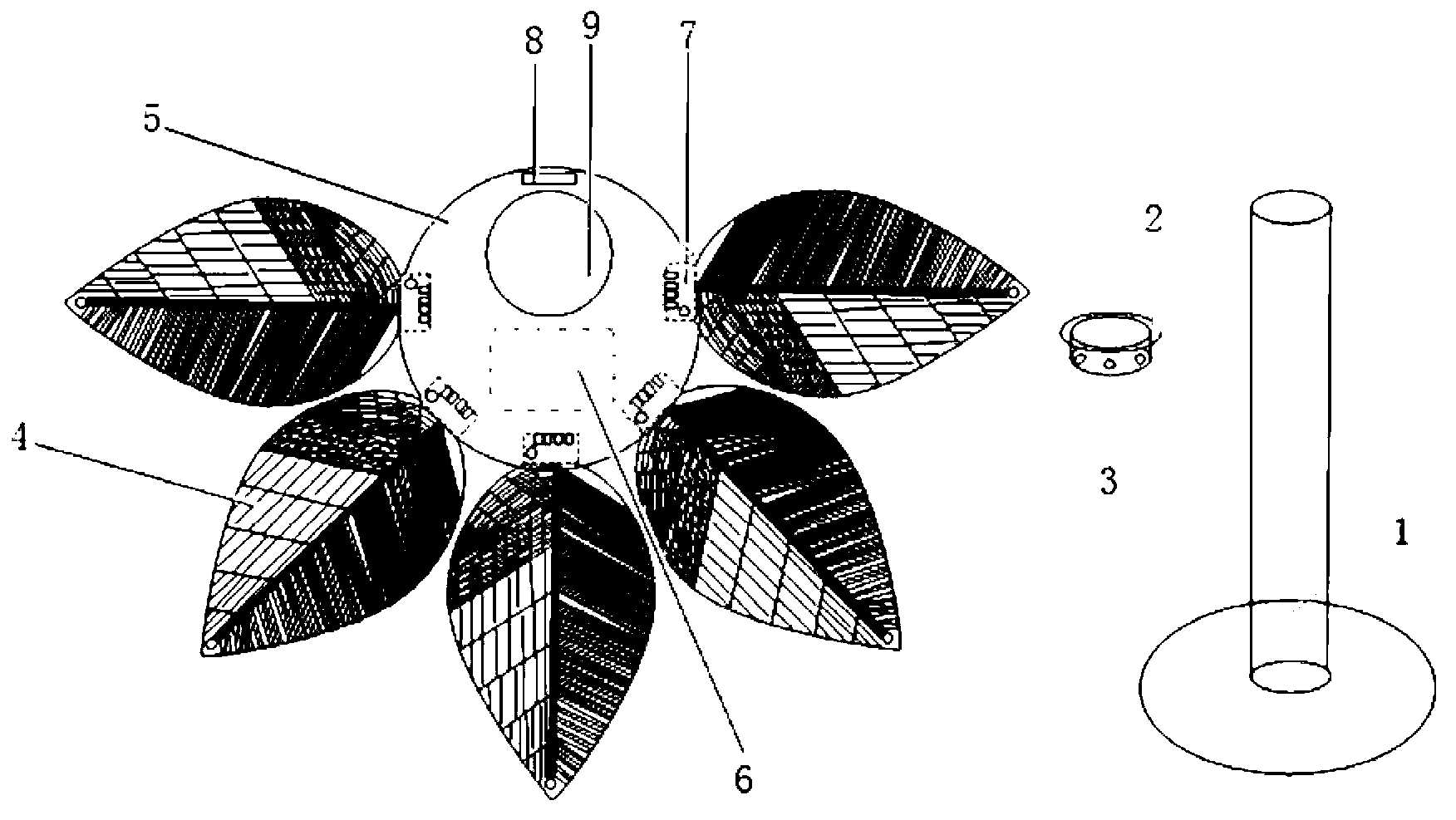

[0052] This embodiment describes a plant leaf surface humidity measuring device, including a collection platform, a fixed platform, a support frame, a golden finger socket, a signal processing circuit, and the above-mentioned leaf surface humidity sensor;

[0053] The collection platform passes through the through hole on the side, passes through the support frame and is placed on the fixed platform;

[0054] The fixed table passes through the support frame and is squeezed and fixed by nuts;

[0055] The blade surface humidity sensor is fixed on the collection platform through a golden finger socket, and is connected with the signal processing circuit;

[0056] The signal processing circuit collects and processes the signal of the humidity sensor on the blade surface and provides a humidity signal with a voltage of 0-2.5V to the outside.

[0057] The plant leaf surface humidity measuring device can adjust the number of leaves according to the actual leaf size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com