Wave-transmitting material based on artificial metal microstructure unit and radome

A technology of artificial metal and wave-transmitting material, applied in the directions of radiation unit cover, antenna, electrical components, etc., can solve the problems of loss, electromagnetic wave reflected energy, etc., to achieve the effect of impedance matching, increase transmission, and reduce reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

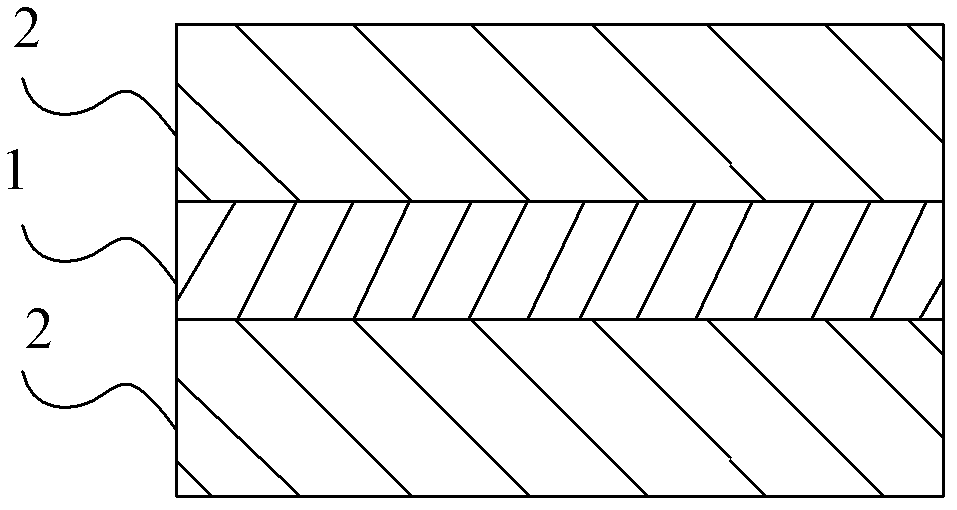

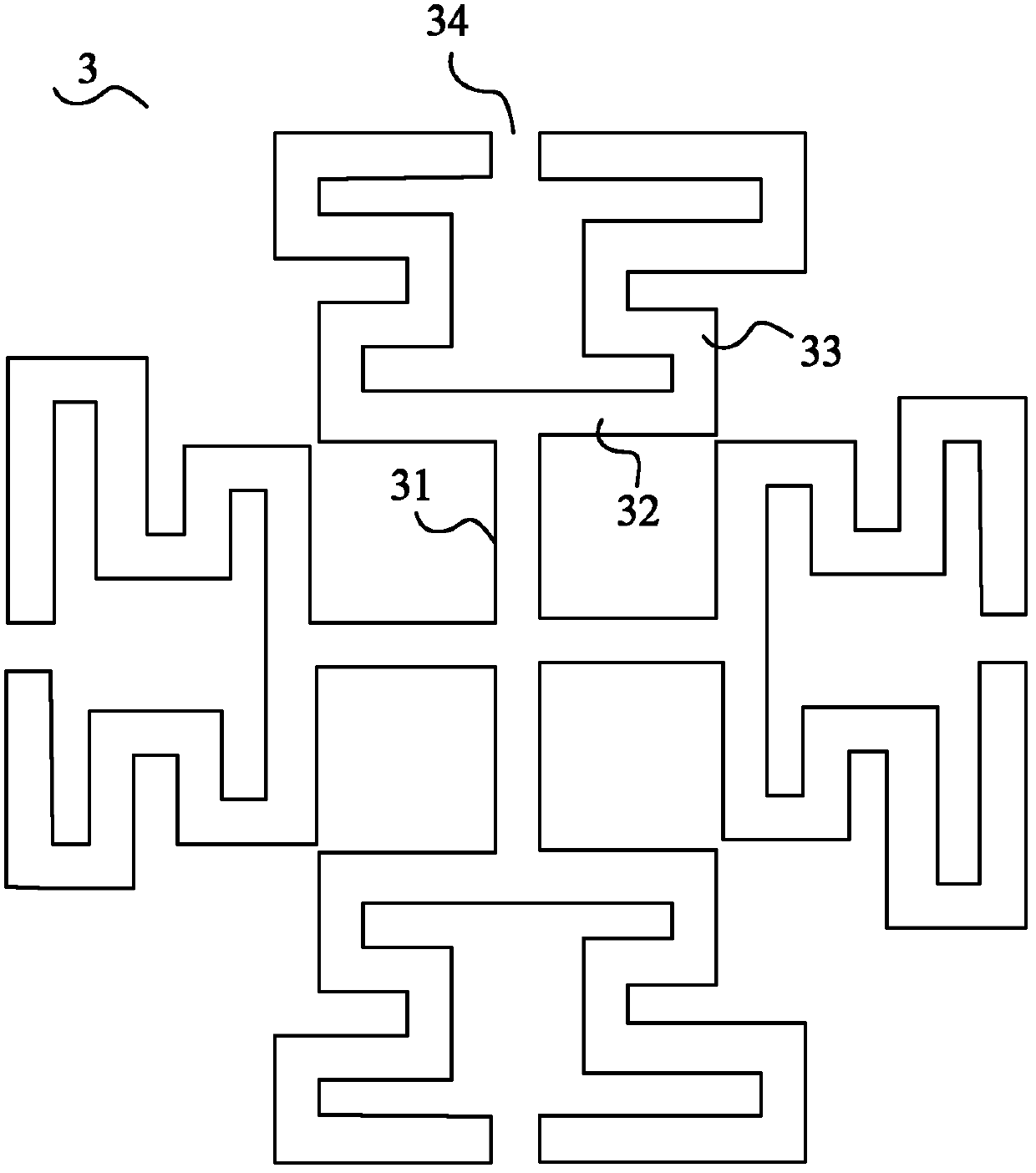

[0020] see figure 1 and figure 2 , the present invention provides a wave-transparent material based on artificial metal microstructure units, the material includes a plurality of material sheets, each material sheet includes a substrate 1, two cladding plates 2 and sandwiched between the substrate 1 and the The artificial metal microstructure 3 in the middle of the cladding plate 2, the substrate 1 is made of ceramic material, polytetrafluoroethylene material, ferroelectric material, ferrite material, ferromagnetic material or is FR-4 epoxy glass cloth layer platen. In this embodiment, the substrate 1 is a FR-4 epoxy glass cloth laminated board, which has low price, good adhesion, low moisture absorption, good insulation, good flame resistance, good stability, and good electrical performance Etc.

[0021] The substrate 1 is virtually divided into a plurality of substrate units arranged in an array, and each substrate unit is attached with an artificial metal microstructure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com