Heating plate without electromagnetic radiation

An electromagnetic radiation and heating plate technology, which is applied to electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of rising costs, affecting heat transmission, and worsening heating effect of heating plates, and achieving low production costs and ease of use. Implementation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

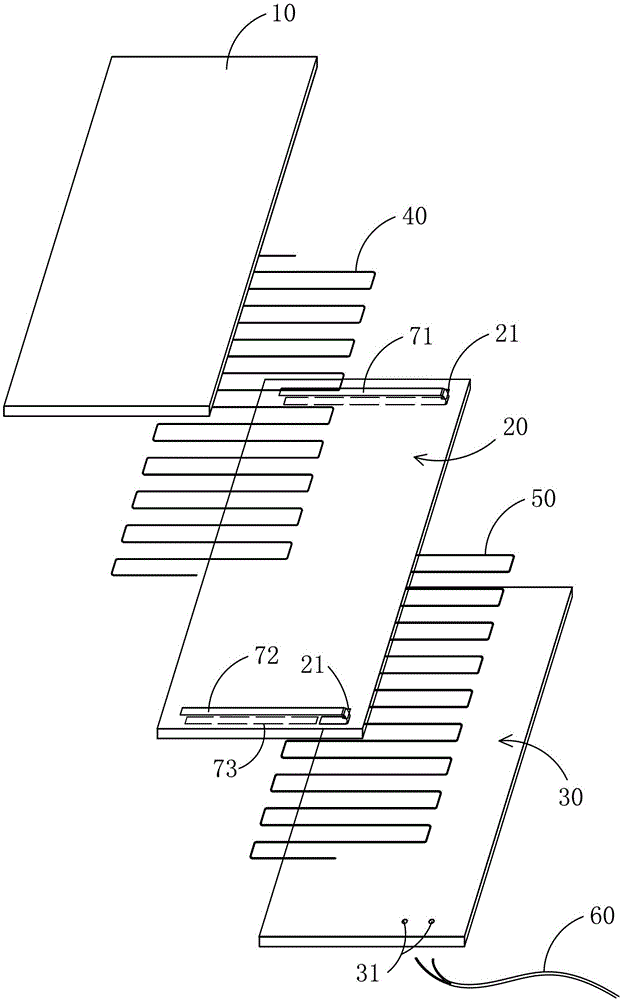

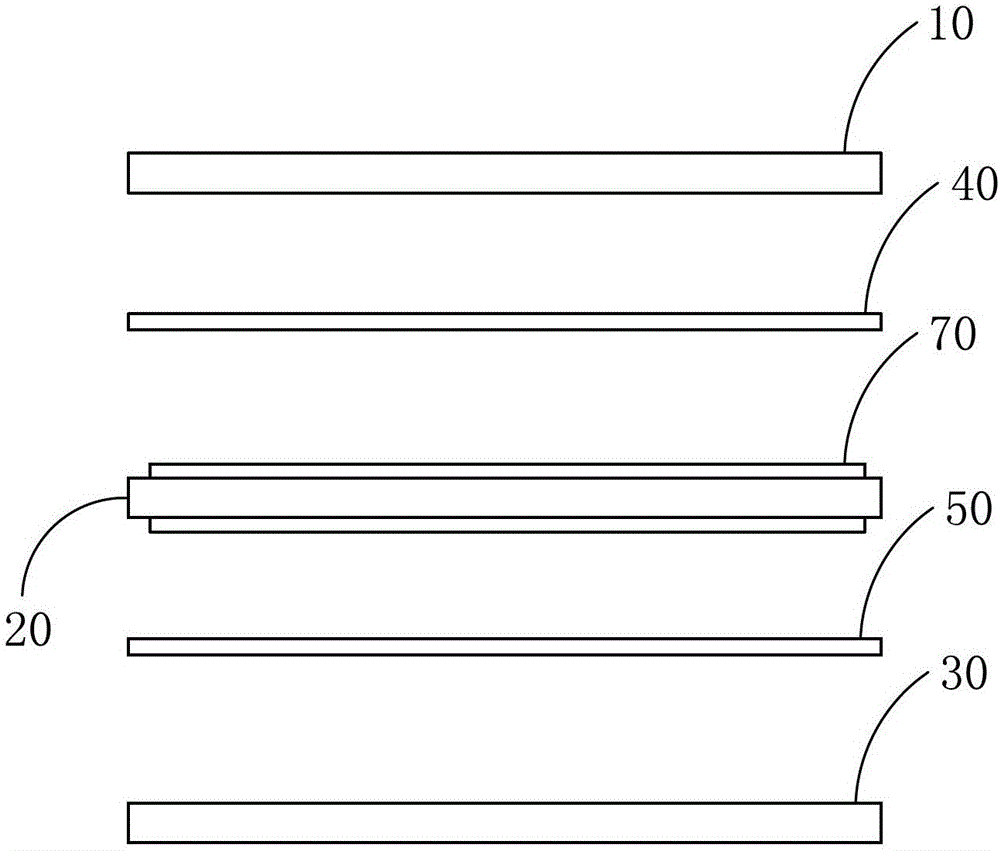

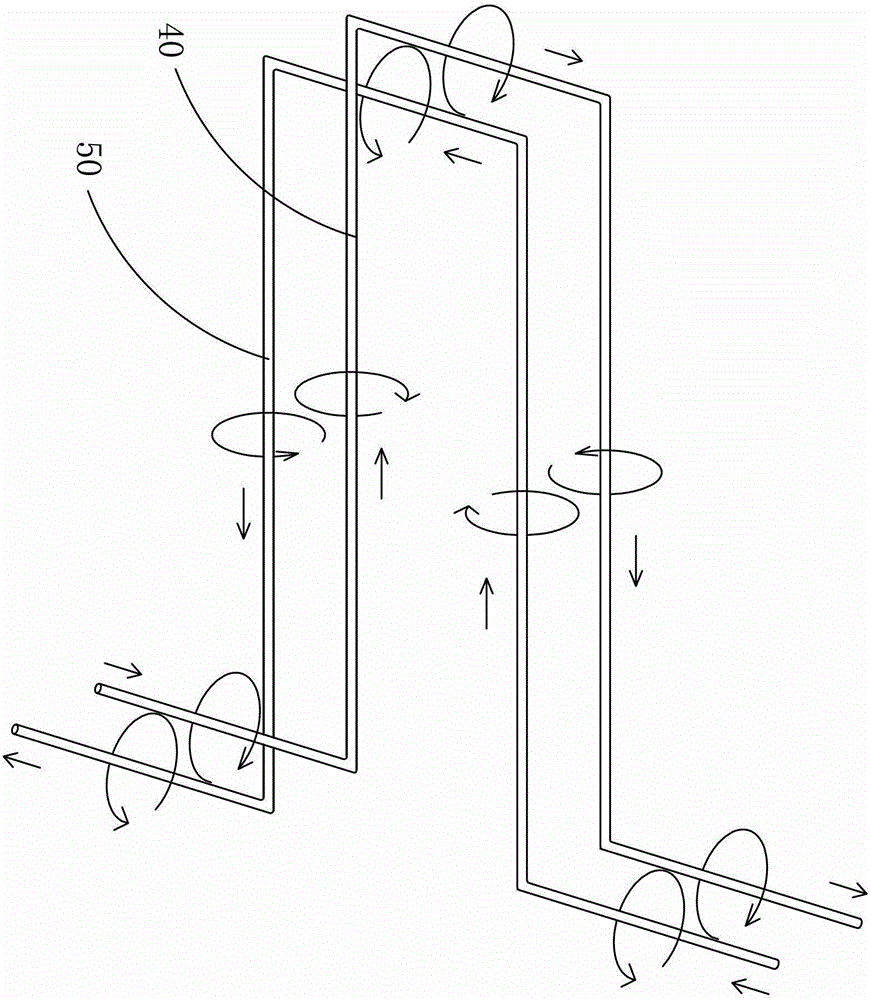

[0016] Such as figure 1 , figure 2 As shown, the heating plate without electromagnetic radiation of the present invention is composed of an upper insulating plate 10, an intermediate insulating plate 20, and a lower insulating plate 30, and the upper and lower sides of the intermediate insulating plate 20 are respectively provided with heating wires for revolving wiring. 40 and the wire 50, and the positions of the heating wire 40 and the wire 50 are corresponding, and the heating wire 40 and the wire 50 are connected with the external power wire 60 to form a loop. When the external power line 60 is powered on, the heating wire 40 and the wire 50 are energized to generate electromagnetic fields with opposite directions and equal magnitudes, and the electromagnetic fields cancel each other out so that the total amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com