High-efficient and energy-saving type industrialized double-circulating breeding system

A breeding system and circulation system technology, applied in the field of high-efficiency and energy-saving industrialized double-circulation breeding system, to achieve the effects of high dissolved oxygen content, high water treatment efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

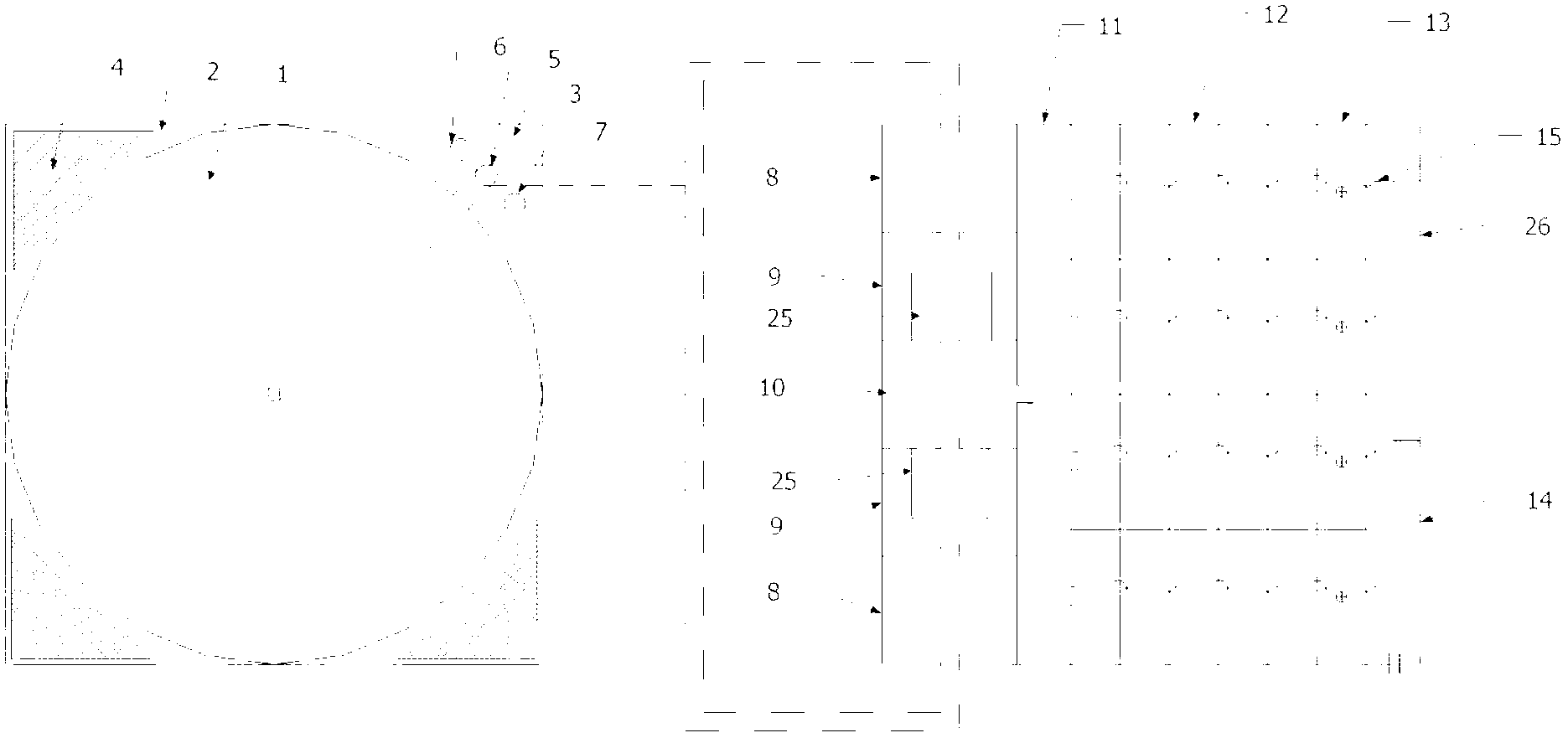

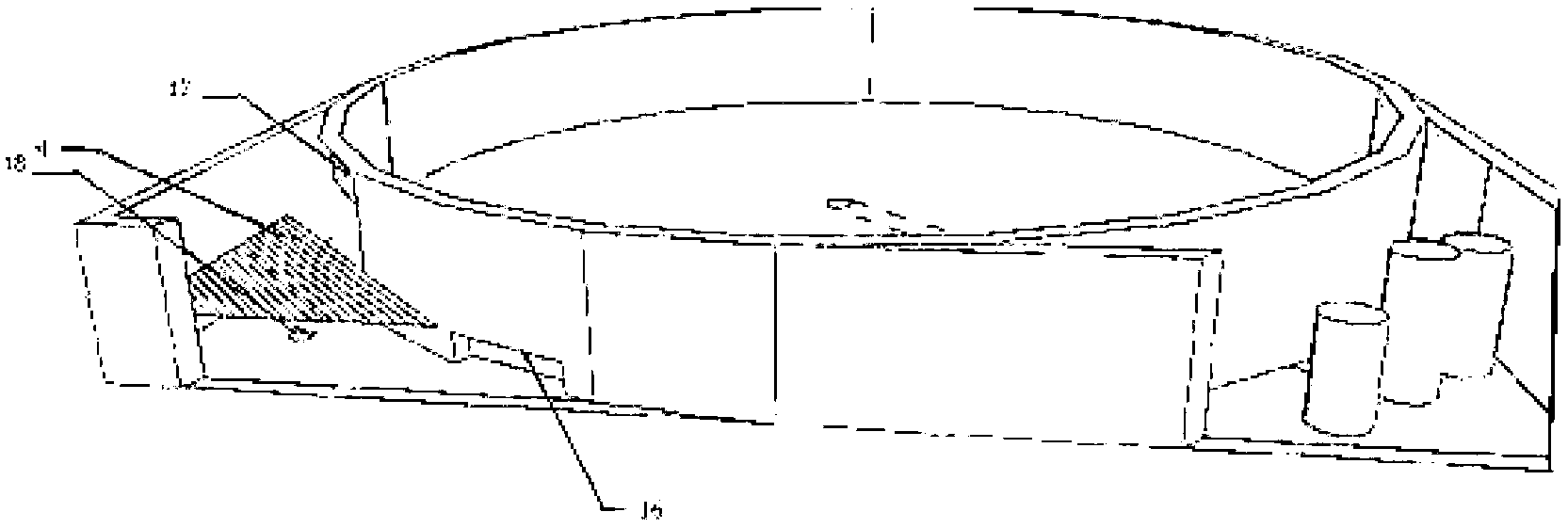

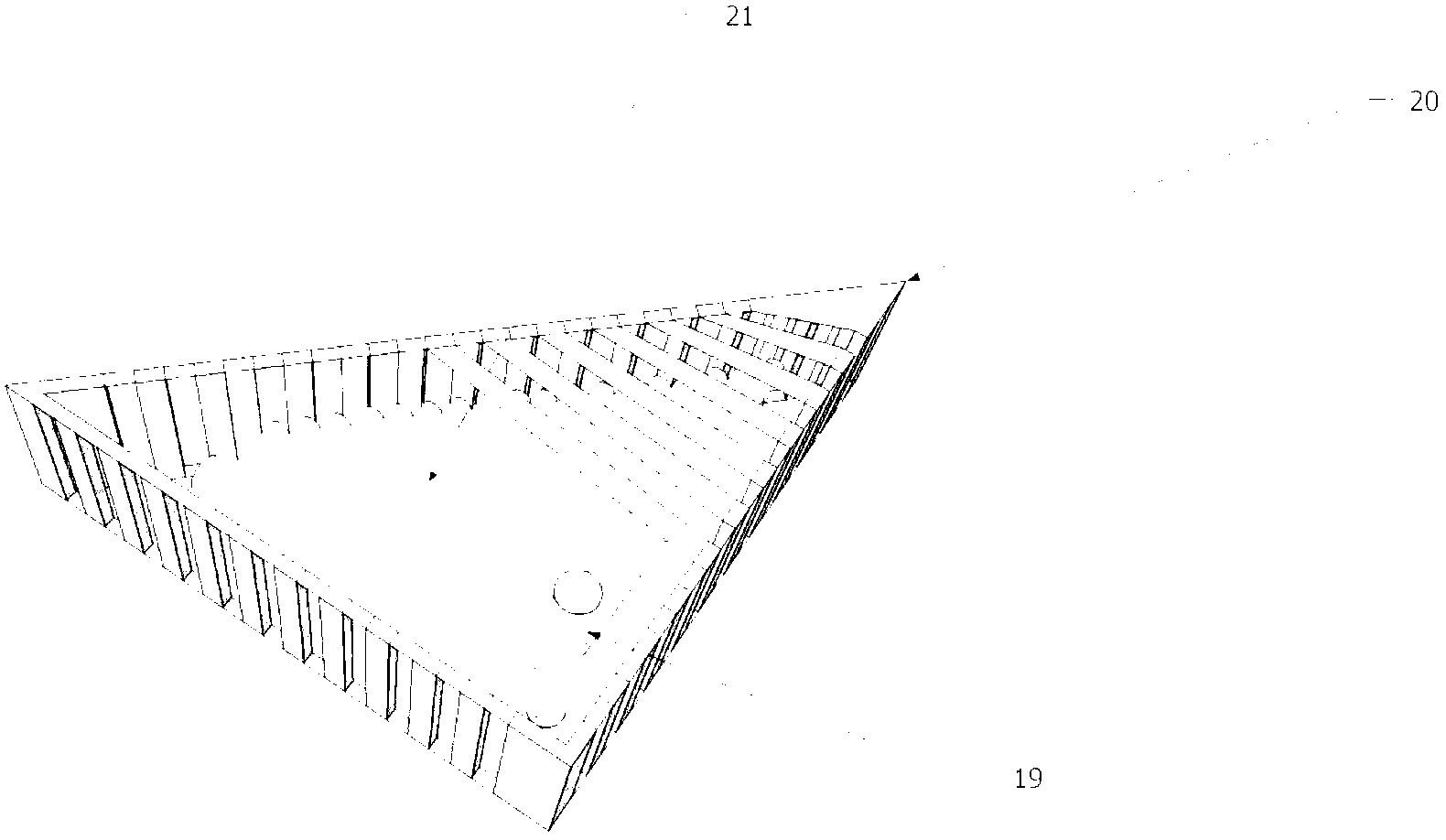

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] see Figure 1-5 , a high-efficiency and energy-saving factory double-circulation breeding system, which is composed of a breeding pond 1, an internal circulation system and an external circulation system, the surrounding of the cultivation pond is provided with an internal circulation system and an external circulation system, and the internal circulation system includes an air lift tank 2, Combined air lift device 4 is provided in the gas pool, and the bottom of the pool wall at the junction of the culture pool 1 and the air lift tank is respectively provided with an air lift tank water inlet 16 and an air lift tank water outlet 17, and the water outlet direction of the air lift tank outlet is the same as that of the culture tank. The direction of water flow is the same, and the bottom of the water outlet of the air-lift tank is located at 5 cm b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com