Method and structure for ensuring synchronization of notch wheels of reciprocating material pulverizing machine

A crushing machine and ratchet technology, applied in the direction of grain processing, etc., can solve the problems of accelerated discharge speed of the crushing box, lengthening of the crushing unit, and large cumulative error, so as to eliminate the difference in the number of teeth of the ratchet, ensure the residence time, and produce reliably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

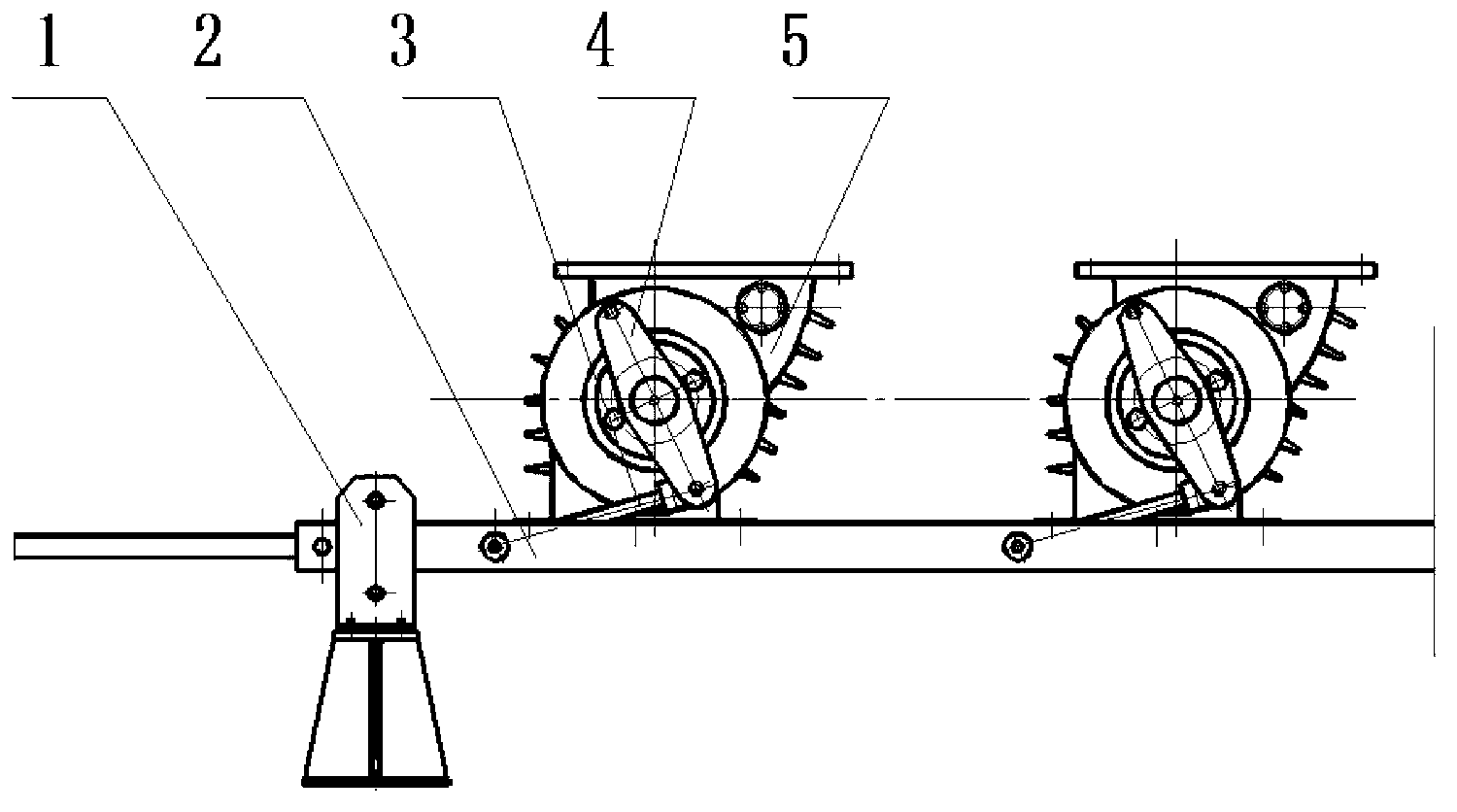

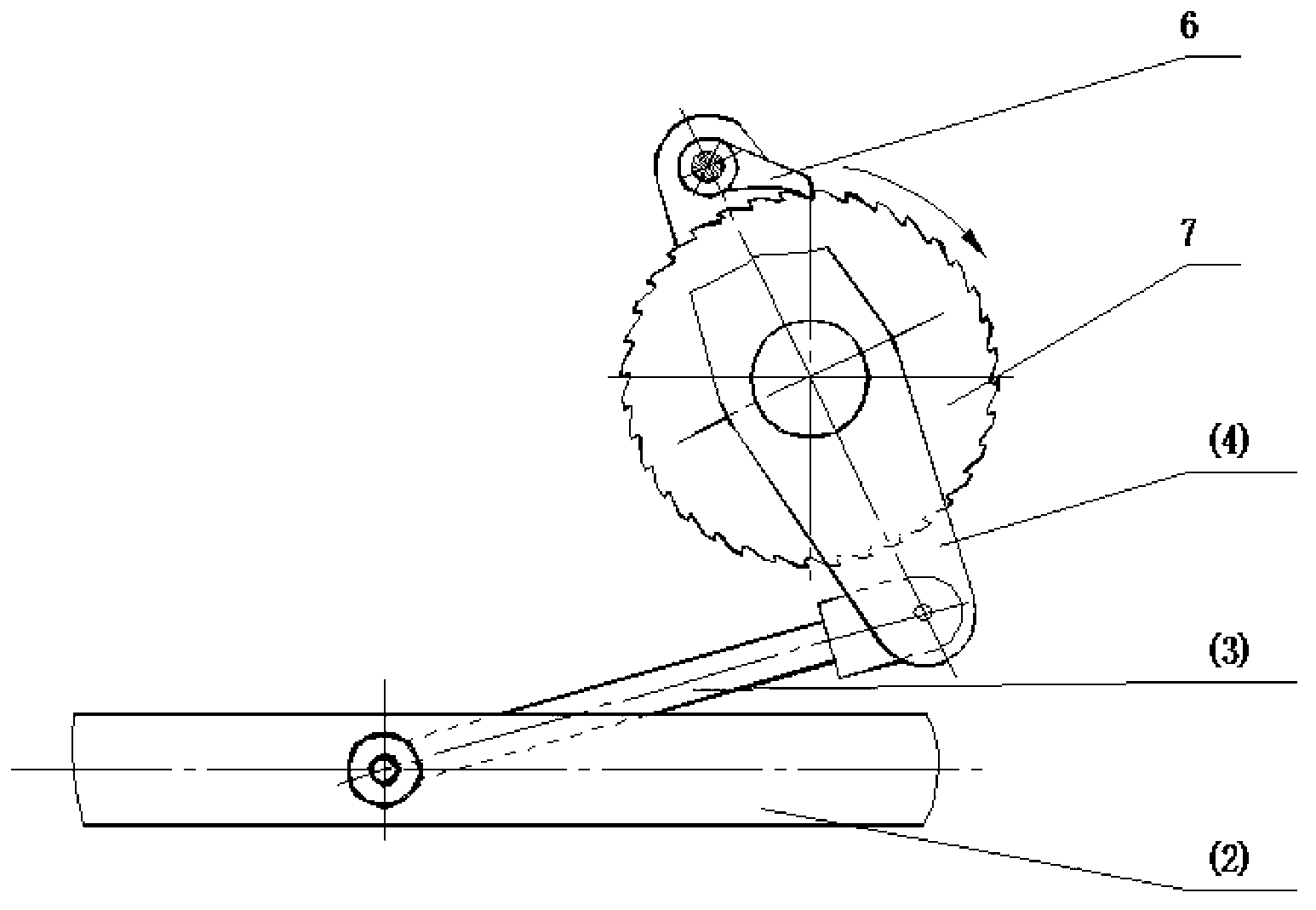

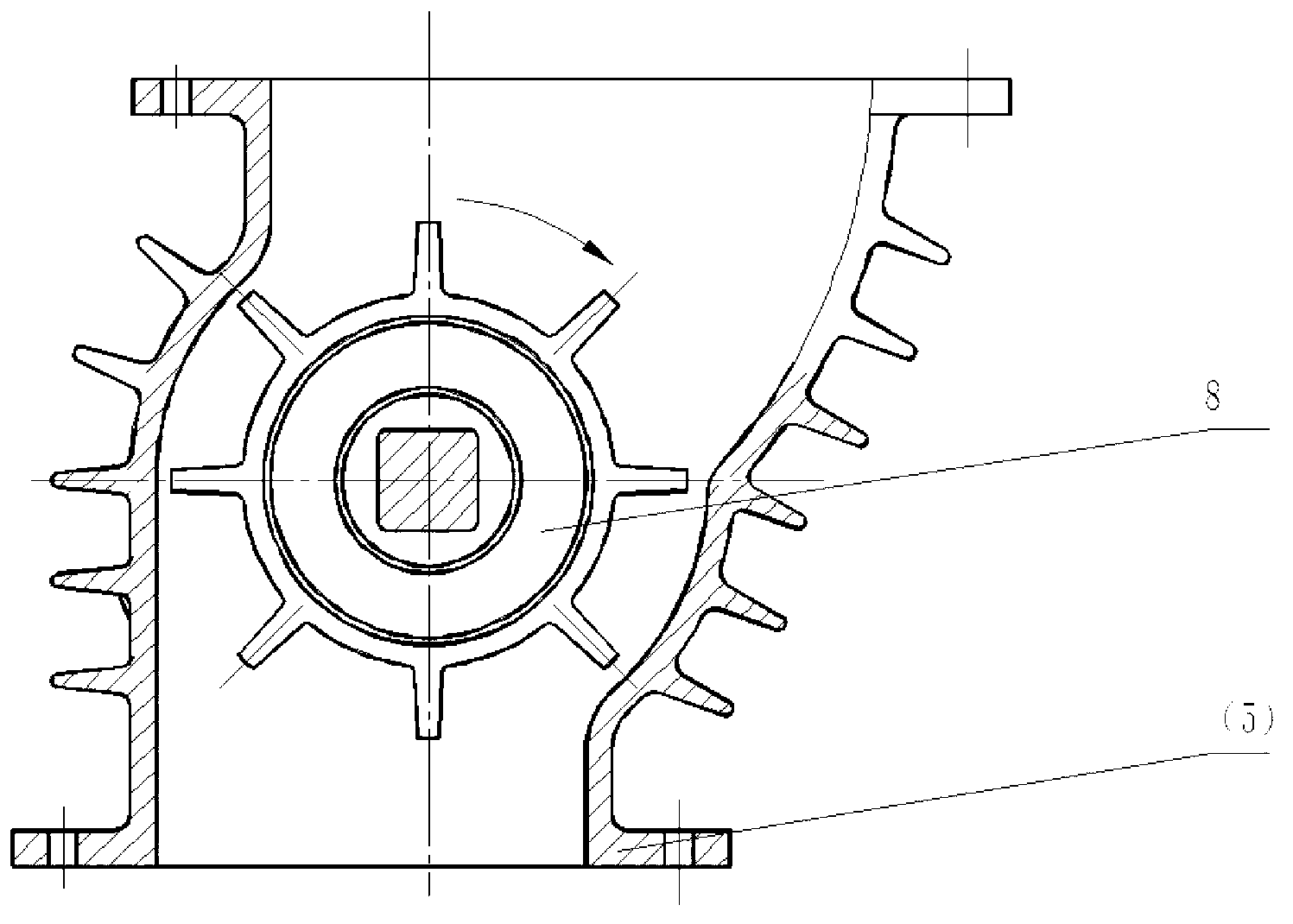

[0017] Such as figure 1 , Shown in 2 and 3, the horizontal pull rod 2 can move left and right in the pull rod guide 1. One end of each rocker lever 3 is connected with the horizontal pull rod 2, and the other end is connected with each ratchet lever 4. The ratchet 6 and the ratchet 7 that is connected at the other end of the ratchet lever 4 form a ratchet pair that can drive the crushing roller 8 in each crushing box 5 to rotate. When the horizontal pull bar 2 moved to the left, each ratchet lever 4 rotated counterclockwise around the center under the promotion of each rocker lever 3, and at this moment, the ratchet 6 just slid on the ratchet 7. When the horizontal pull bar 2 moved to the right, each ratchet lever 4 rotated clockwise around the center under the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com