A production process of work rolls for rod, wire and hot-rolled strip mills

A production process and work roll technology, which is applied to the special production process field of high-alloy centrifugal composite rolls, can solve the problem of high alloy content in the core, and achieve the effects of reducing carbide content, avoiding roll breakage, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

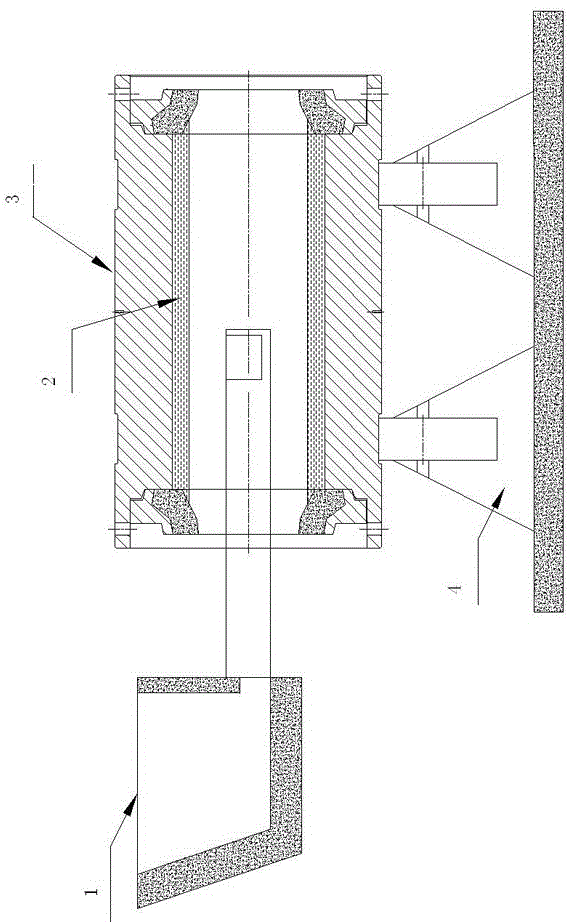

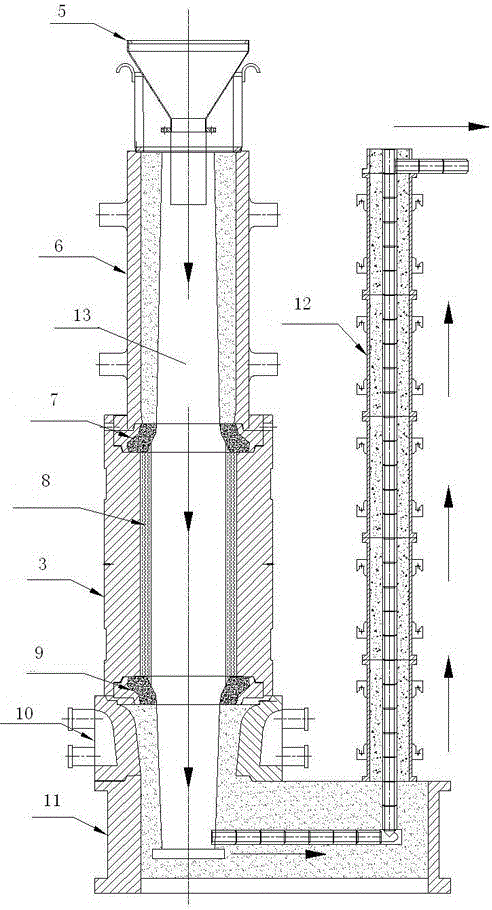

[0018] Example 1: Taking the production of rolls for a certain domestic bar mill with a diameter of φ370×600×1710 as an example, the process of producing high-alloy centrifugal composite rods and wires and work rolls for strip mills will be described in detail.

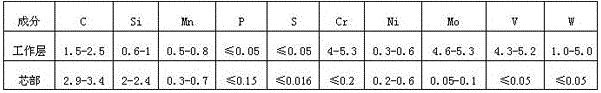

[0019] The high-alloy material used for the working layer is high-speed steel, and the core material is low-alloy nodular cast iron. These materials can meet the performance requirements for the production of centrifugal composite high-alloy rolls. The composition is as shown in Table 1 below (both are weight percentages, and the balance is iron):

[0020]

[0021] Table 1

[0022] The specific process steps of the centrifugal composite high-speed steel roll are as follows: a. Use high-speed steel materials to smelt the molten iron in the working layer through an intermediate frequency furnace; b. Use ordinary low-alloy nodular cast iron materials to smelt the core molten iron in an intermediate-frequency furnace; ...

Embodiment 2

[0023] Example 2: Taking the production of φ340×600×1465 rolls for a domestic high-speed rolling mill as an example, the process of producing high-alloy centrifugal composite rods and work rolls for strip mills will be described in detail.

[0024] The high-alloy material used in the working layer of this roll is also made of high-speed steel. Due to the different working conditions of the rolling mill, the composition is slightly different from the previous one. The core material is made of low-alloy nodular cast iron. The rolls produced by these materials can also meet user requirements. The composition is shown in Table 2 below (both are weight percentages, and the balance is iron):

[0025]

[0026] Table 2

[0027] The specific process steps of the centrifugal composite high-alloy roll are as follows: a. Use high-speed steel materials to smelt the molten iron in the working layer through an intermediate frequency furnace; b. Use ordinary low-alloy nodular cast iron mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com