Torque distribution method of four-wheel drive electric vehicle

A torque distribution method and electric vehicle technology, applied in electric vehicles, control drives, vehicle components, etc., can solve problems such as wheel locking, not fully considering the state of yaw moment adhesion coefficient, and affecting vehicle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

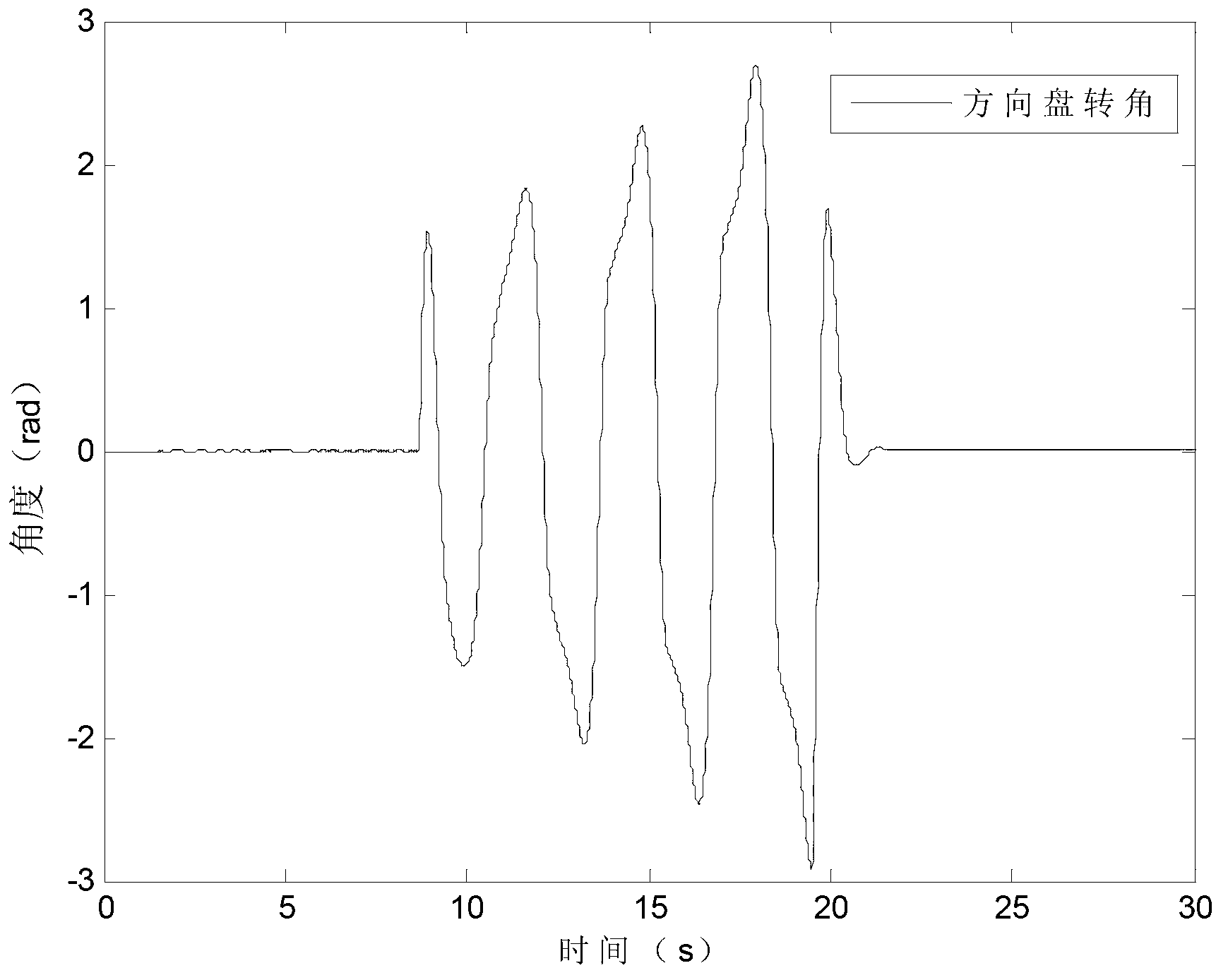

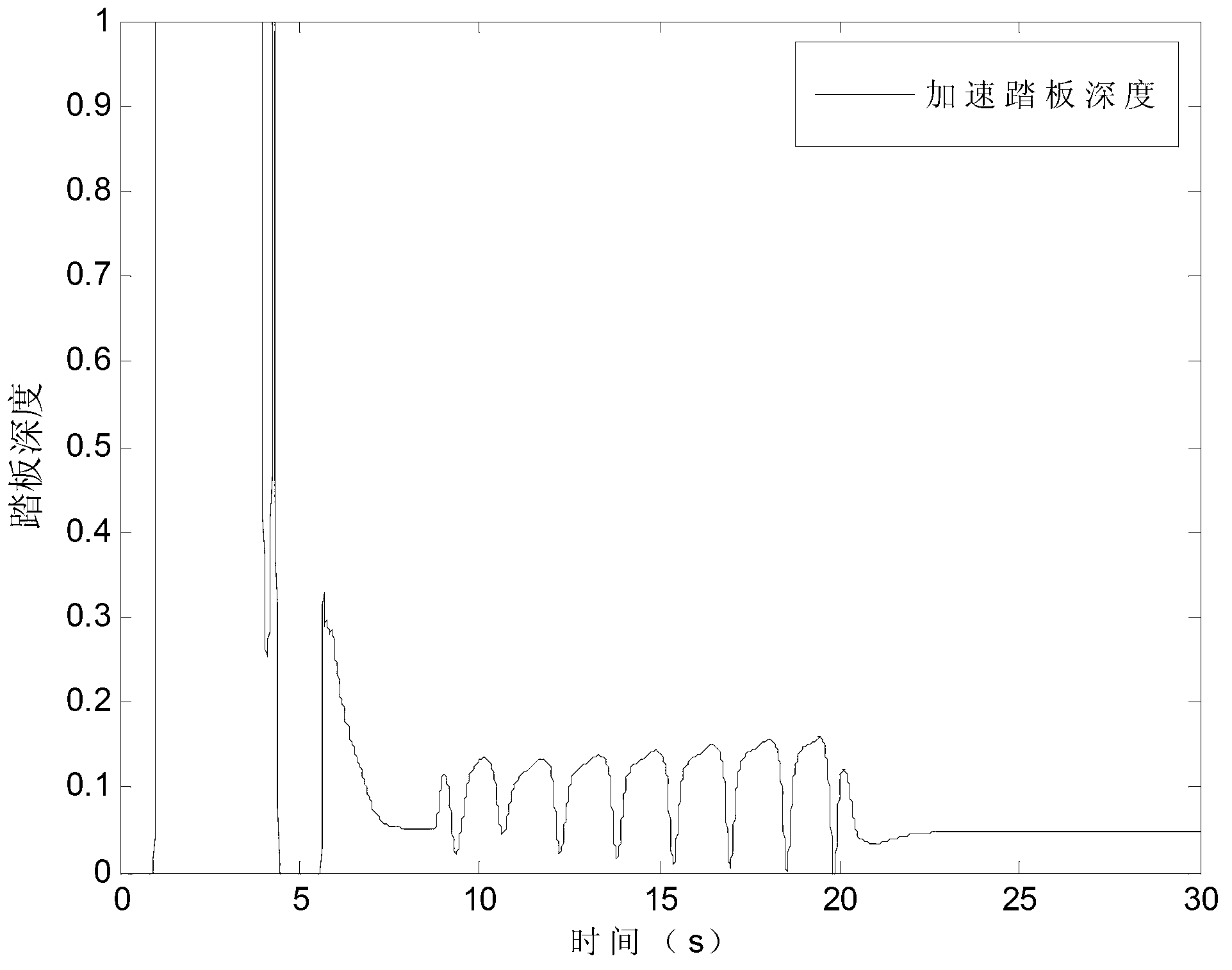

[0103] For the total mass of 1296kg, the moment of inertia around the Z axis is 1750kgm2, the wheelbase is 2.57m, the distance from the center of mass to the front axle is 1.25m, the distance from the center of mass to the rear axle is 1.32m, the front wheelbase is 1.405m, the rear wheelbase is 1.399m, and the height of the barycenter is 0.45 m, and a four-wheel drive electric vehicle with a wheel radius of 0.326m is used for verification. The speed of the vehicle is increased from 0km / h to 70km / h, and at the same time, it bypasses 7 obstacles within 8 to 25s, simulating the serpentine movement condition, and the friction coefficient of the road surface is set to u=0.7, which is normal for dry asphalt roads coefficient of friction.

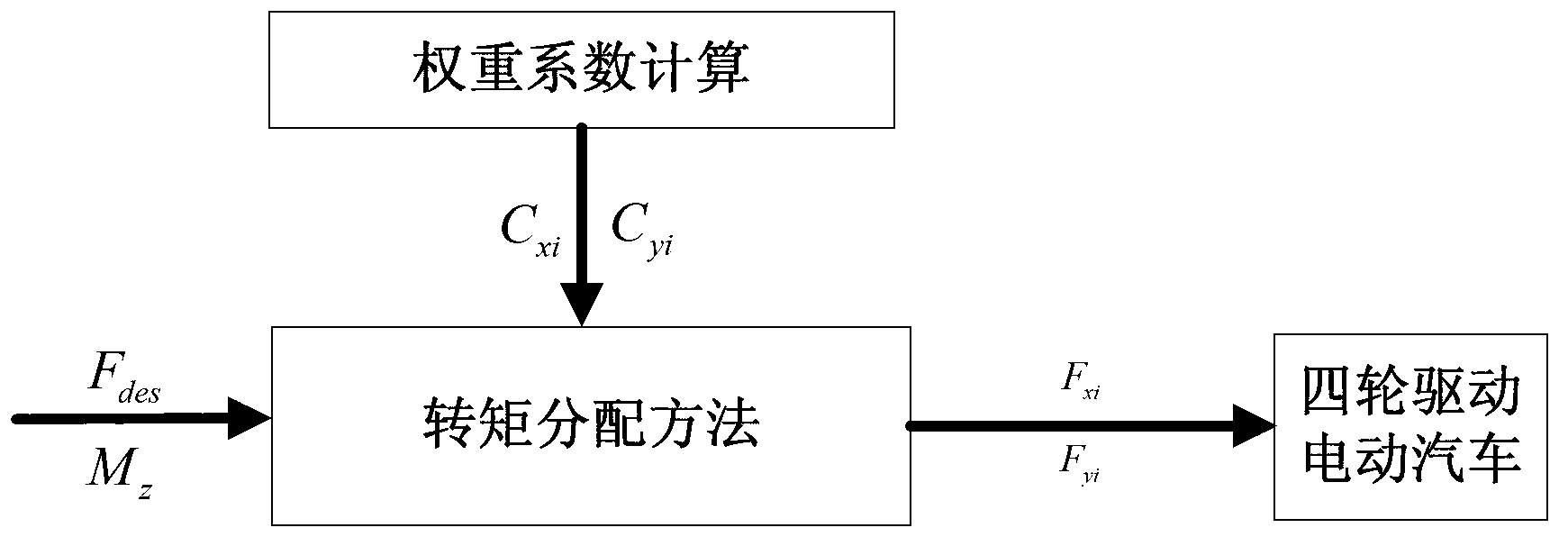

[0104] figure 1 The shown four-wheel drive electric vehicle torque distribution method first uses the vehicle sensor system to collect the real-time driving torque (T i ) and yaw moment value (M z ); then determine the longitudinal force weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com