Water-based anticorrosive coating with rust and preparation method thereof

A coating and water-based technology, which is applied in the field of water-based rust and anti-corrosion coatings and its preparation, can solve the problems of insufficiently dense coating film, poor physical and mechanical properties of the coating film, poor waterproof and permeability resistance, etc., and achieves excellent physical and chemical properties. Outstanding aging and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]

[0080]

[0081] Preparation:

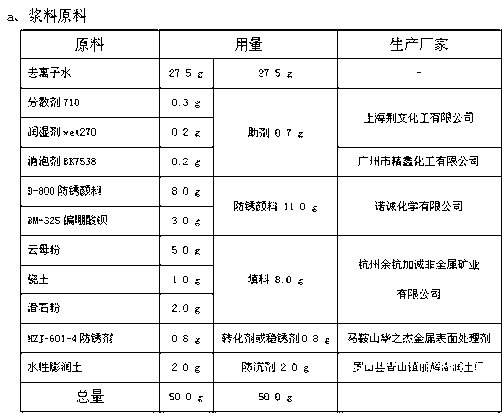

[0082] The first step: preparation of slurry:

[0083] Stir deionized water, dispersant, wetting agent, defoamer and HZJ-601-4 anti-rust agent evenly, add anti-sedimentation agent under stirring condition, stir and disperse for 15 minutes, then add anti-rust pigment, barium metaborate and filler Stir and disperse at high speed for 30 minutes, then grind with a mill, and take samples for inspection. The particle size of the product should reach about 25??m to make a slurry;

[0084] The second step: preparation of paint:

[0085] Add fluorine-containing rust-bearing emulsion to the slurry obtained in the first step under stirring conditions, and add color paste, bactericide, leveling agent, defoamer, conversion agent or rust stabilizer mixed with the remaining part of deionized water after stirring , stirred for 30 minutes to discharge, and filtered to obtain a rust-resistant anti-corrosion coating.

[0086] Formula of fluorine-c...

Embodiment 2

[0099]

[0100]

[0101] Preparation:

[0102] The first step: preparation of slurry:

[0103] Stir deionized water, dispersant, wetting agent, defoamer and HZJ-601-4 anti-rust agent evenly, add anti-sedimentation agent under stirring condition, stir and disperse for 15 minutes, then add anti-rust pigment, barium metaborate and filler Stir and disperse at high speed for 30 minutes, then grind with a mill, and take samples for inspection. The particle size of the product should reach about 25??m to make a slurry;

[0104] The second step: preparation of paint:

[0105] Under the condition of stirring, add the fluorine-containing rust emulsion into the slurry obtained in the first step, after stirring, add the color paste, bactericide, leveling agent, defoamer, conversion agent or rust stabilizer, stir for 30 minutes, discharge, filter, and make Anti-corrosion paint with rust.

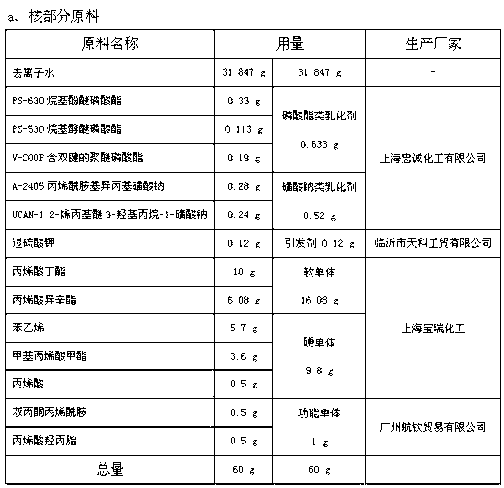

[0106] Formula of fluorine-containing emulsion with rust

[0107]

[0108]

[0109] P...

Embodiment 3

[0119]

[0120]

[0121] Preparation:

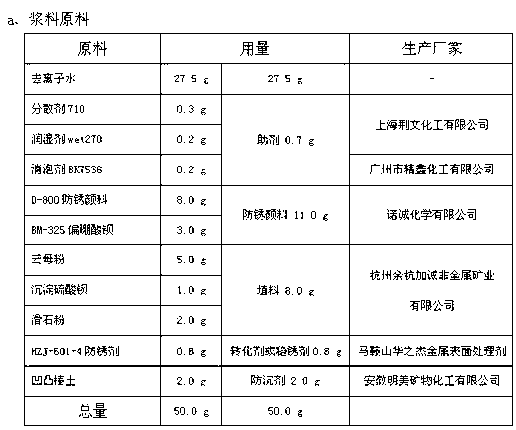

[0122] The first step: preparation of slurry:

[0123] Stir deionized water, dispersant, wetting agent, defoamer and HZJ-601-4 anti-rust agent evenly, add anti-sedimentation agent under stirring condition, stir and disperse for 15 minutes, then add anti-rust pigment, barium metaborate and filler Stir and disperse at high speed for 30 minutes, then grind with a mill, and take samples for inspection. The particle size of the product should reach about 25??m to make a slurry;

[0124] The second step: preparation of paint:

[0125] Add fluorine-containing rust-bearing emulsion to the slurry obtained in the first step under stirring conditions, and add color paste, bactericide, leveling agent, defoamer, conversion agent or rust stabilizer mixed with the remaining part of deionized water after stirring , stirred for 30 minutes to discharge, and filtered to obtain a rust-resistant anti-corrosion coating.

[0126] Formula of fluori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com