Liquid crystal composition capable of rapidly responding to cyclo-butylbenzene difluoromethoxy

A technology of cyclobutadiene difluoromethoxy and liquid crystal composition, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of liquid crystal materials such as high viscosity at low temperature, animation smear, and large temperature dependence, and achieve Effects of high resistivity and voltage retention, low overall response time, and low rotational viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

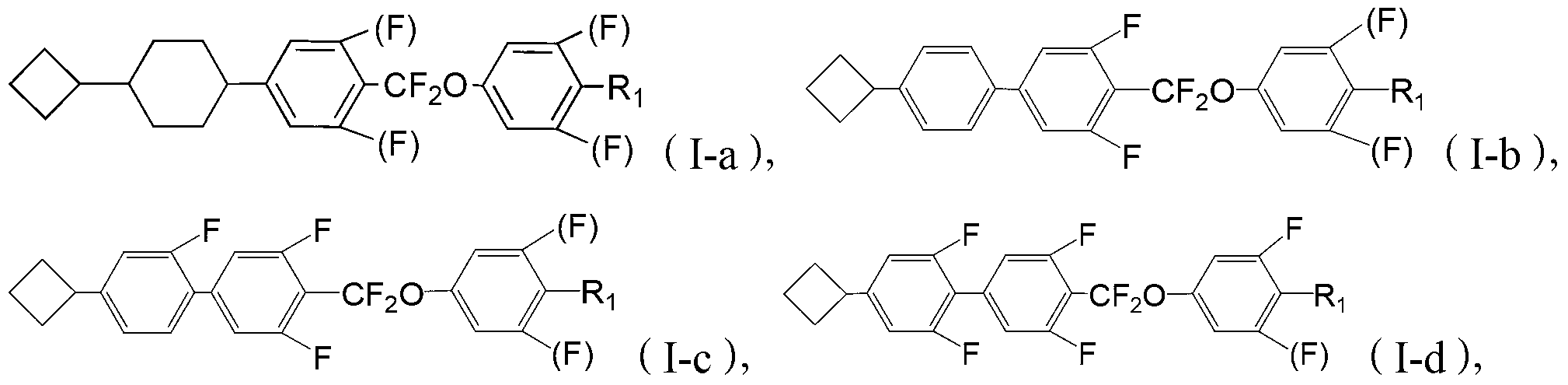

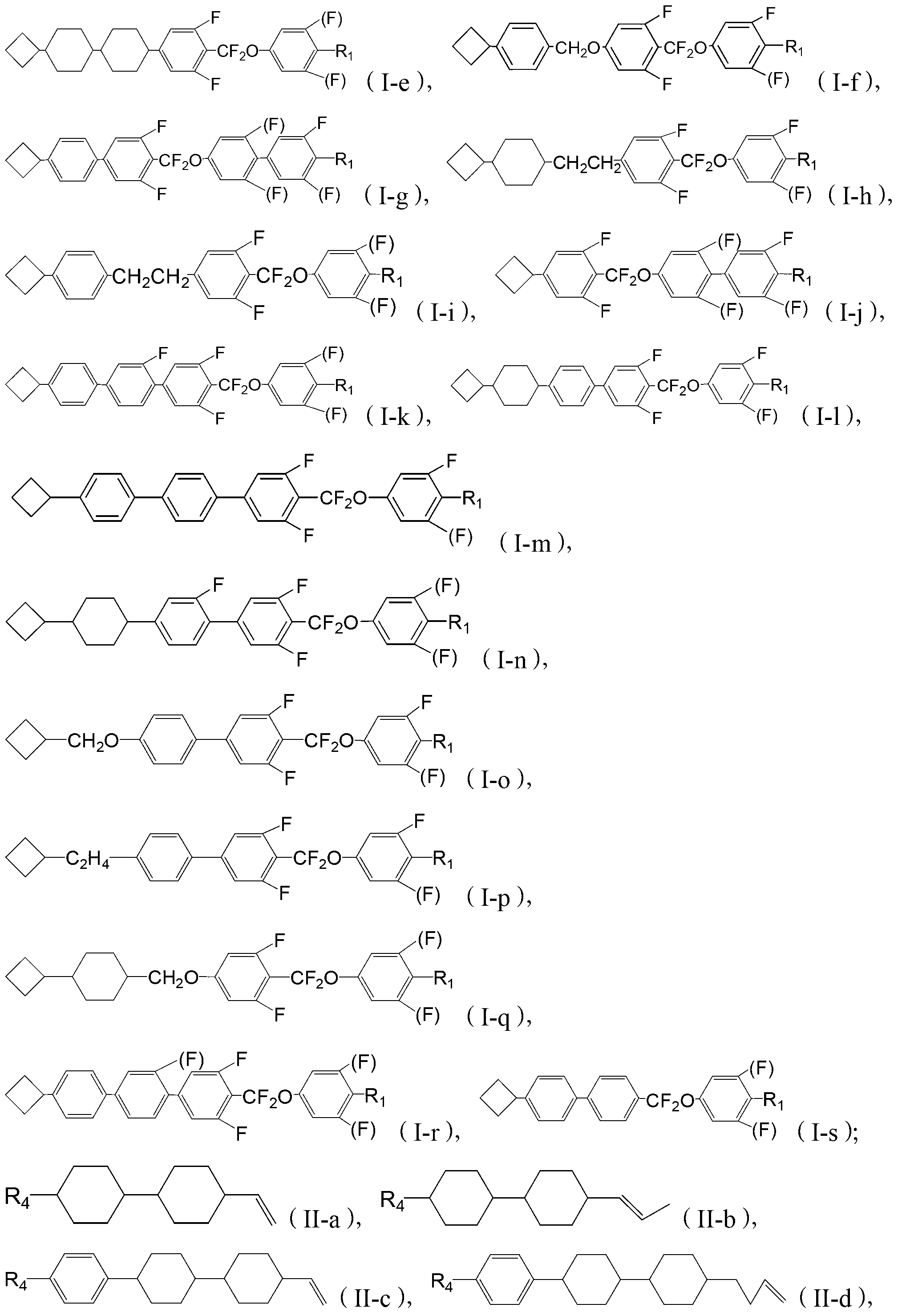

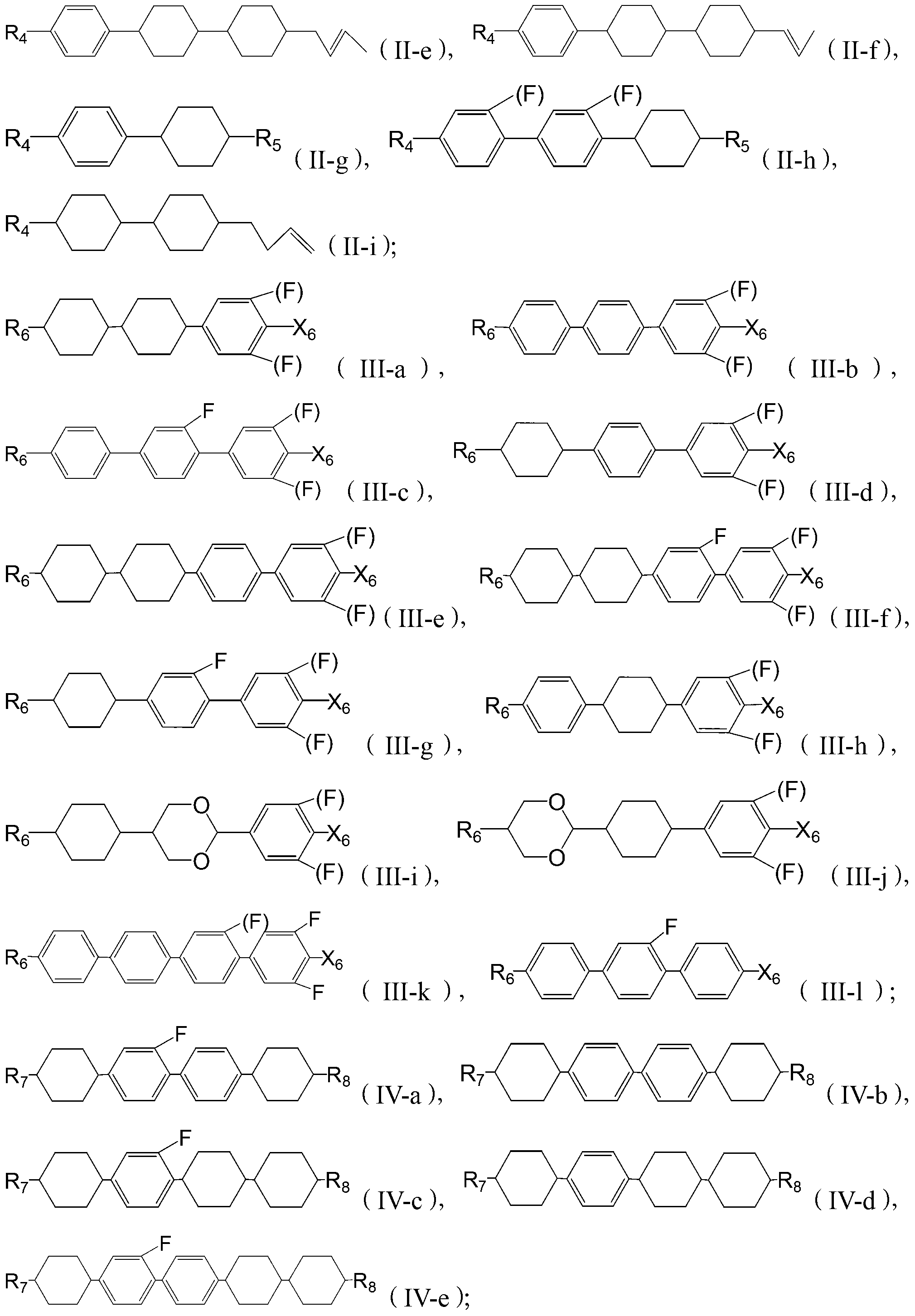

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the examples.

[0034] The percentages in this manual are all mass percentages; the temperature is in degrees Celsius (°C); the specific meanings and test conditions of other symbols are as follows:

[0035] c.p. (°C) represents the clearing point of liquid crystal; S-N represents the melting point (°C) of liquid crystal from crystalline state to nematic phase; △n is optical anisotropy, no is the refractive index of ordinary light, and ne is the refractive index of extraordinary light , the test conditions are: 589nm, 25°C; △ε is the dielectric anisotropy, △ε=ε∥-ε⊥, where ε∥ is the dielectric constant parallel to the molecular axis, ε⊥ is the dielectric constant perpendicular to the molecular axis Dielectric constant, the test conditions are: 25°C, 1KHz, HP4284A, 5.2 micron TN left-handed box; τ is the response time (ms), the test instrument is DMS-501, the test conditions are: 25±0.5°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com