Method for processing environment-friendly deep soft soil shallow foundation and device for reinforcing foundation

An environment-friendly, foundation treatment technology, applied in soil protection, infrastructure engineering, sheet pile walls, etc., can solve problems such as high engineering cost, damage to underground water channels, and impact on the ecological environment around the foundation, and achieve high social benefits. , The effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

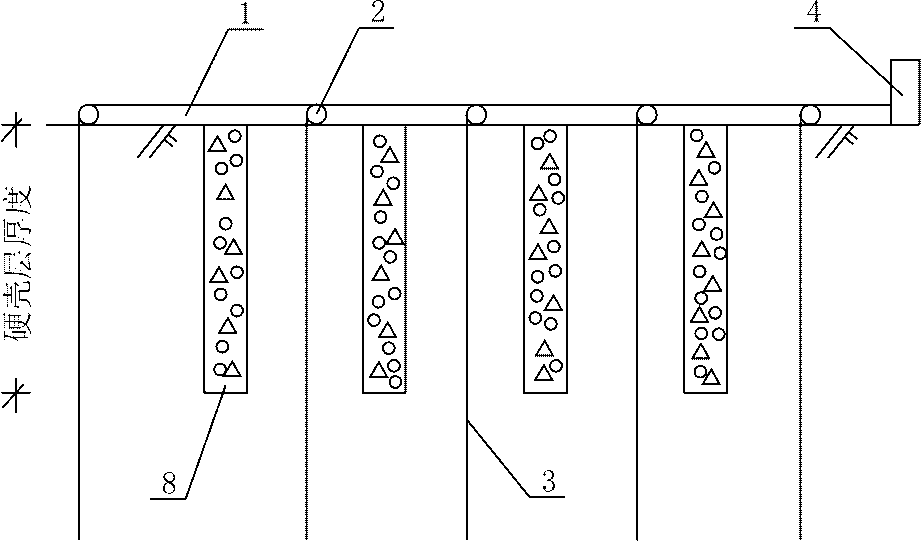

[0044] Embodiment 1: In the step 5), the foundation pile driven by the piling machine adopts an environmentally friendly lightweight material pile 8, which cooperates with the plastic drainage board 3 to form a light hard shell layer, and the material of the environmentally friendly lightweight material pile 8 It is composed of the following three raw materials: ①quicklime, ②cement or waste gypsum or sodium sulfate powder, ③fly ash or slag or slag, ④ceramic sand or aeolian sand; the parts by weight of each raw material are: ① 1-8 parts of quicklime, ② 1-3 parts of cement or 0.01-2 parts of waste gypsum or 0.01-1 part of sodium sulfate powder, ③ 2-9 parts of fly ash or slag or slag in any proportion, according to the above weight ratio , the material of the environmentally friendly lightweight material pile 8 is light, can react with water and can be cured.

Embodiment 2

[0045] Embodiment 2: Compared with Embodiment 1, other things remain unchanged, only in the step 5), the foundation pile driven by the piling machine is made of environmentally friendly lightweight material pile 8, which works together with the plastic drainage board 3 to form a light hard shell layer , the material of the environmentally friendly lightweight material pile 8 is composed of the following four kinds of raw materials: ① quicklime, ② cement or waste gypsum or sodium sulfate powder, ③ fly ash or slag or slag, ④ ceramsite sand or aeolian sand The parts by weight of each raw material are: ① 1-8 parts of quicklime, ② 1-3 parts of cement or 0.01-2 parts of waste gypsum or 0.01-1 part of sodium sulfate powder, ③ fly ash or slag or slag according to any The ratio is 2 to 9 parts in total, and ④ ceramsite sand or aeolian sand is 1 to 6 parts in any proportion. According to the above weight ratio, the material of the environmentally friendly lightweight material pile 8 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com