Tension machine for automatically controlling prestressed reinforcement tension and retraction amount

A tensioning machine and tensioning technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to check, many obstacles, and prone to errors, so as to avoid human errors, high measurement accuracy, and prevent The effect of random manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

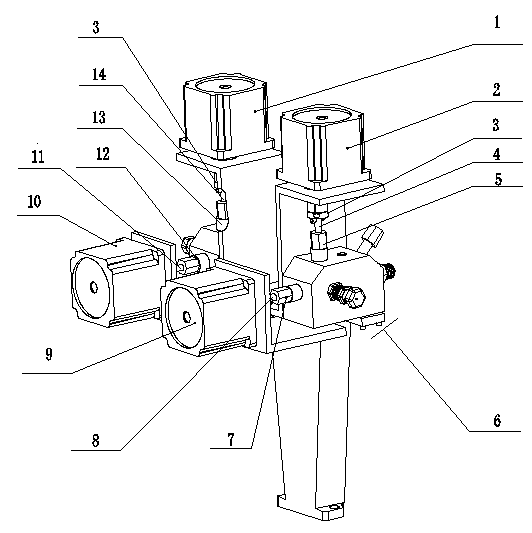

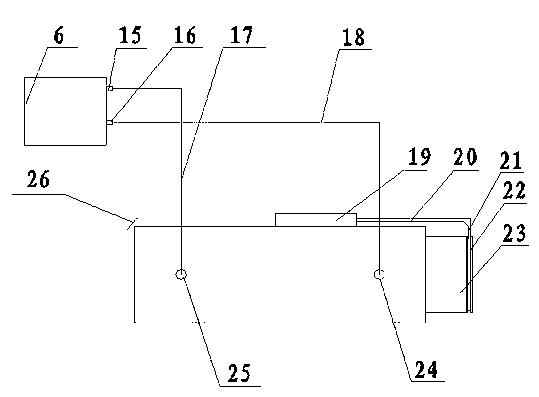

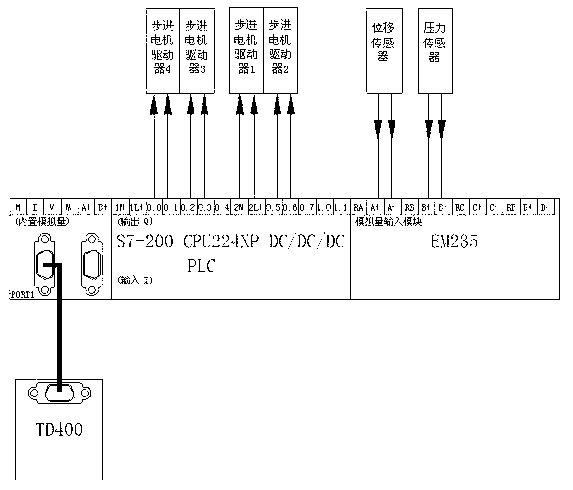

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] The present invention adds a stepping motor to the original high-pressure plunger hydraulic pump 7 (model ZB4-500), and cooperates with the PLC and the stepping motor driver to realize the automatic tensioning process of the automatic tensioning machine to realize the automatic tensioning of the prestressed tendons , figure 1 As shown, it is a schematic diagram of the connection between the stepper motor and the oil cylinder cut-off valve and throttle valve. Remove the manual cut-off valve and throttle valve handwheel on the original high-pressure plunger hydraulic pump 6, add a stepper motor, and remove the handwheel. The return cylinder cut-off valve shaft 4 and the return cylinder cut-off valve stepper motor 5 are connected through a coupling 3, the tension cylinder cut-off valve shaft 14 and the tension cylinder cut-off valve stepper motor 1, the tension cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com