Surface imitation leather process for intermediate decorative plate of automobile door plate

A technology of imitation leather and decorative panels, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of poor product quality, large bending radian, easy to produce bulge, etc., to reduce tensile strength, improve quality, product quality The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

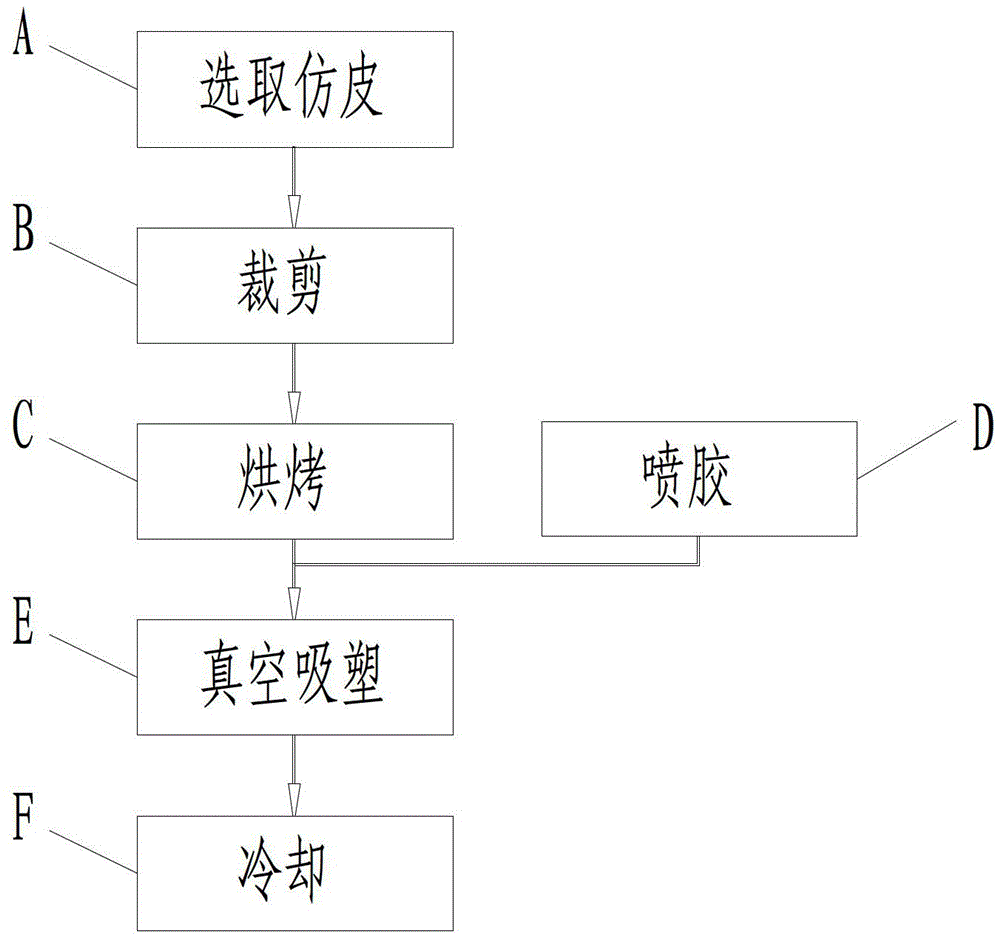

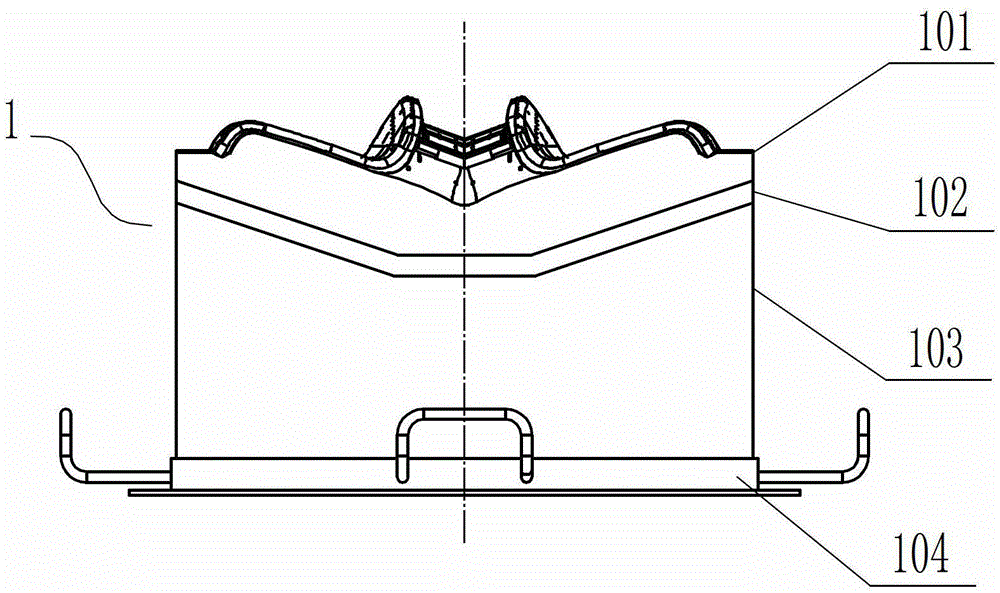

[0057] A process for imitating leather on the surface of a trim panel in a car door panel, comprising the following steps (see figure 1 shown in the flowchart):

[0058] A. Choose Faux Leather:

[0059] The imitation leather with excellent appearance and texture is selected as the decorative layer raw material of the decorative panel workpiece in the car door panel. The physical properties of the imitation leather with excellent appearance and texture are as follows: the thickness of the skin is 0.45-0.47mm, and the longitudinal tensile strength is: 10KG / cm, transverse tensile strength: ≥9KG / cm, longitudinal elongation at break: 170-190%, transverse elongation at break: 140-160%, longitudinal tear strength: 9KG / cm, transverse Tear strength: 7.5KG / cm, foaming ratio of foam layer: 25-30 times, skin forming temperature: 160-170°C / 30 seconds;

[0060] B. cropping:

[0061] Cut the selected imitation leather into the specified size;

[0062] C. bake:

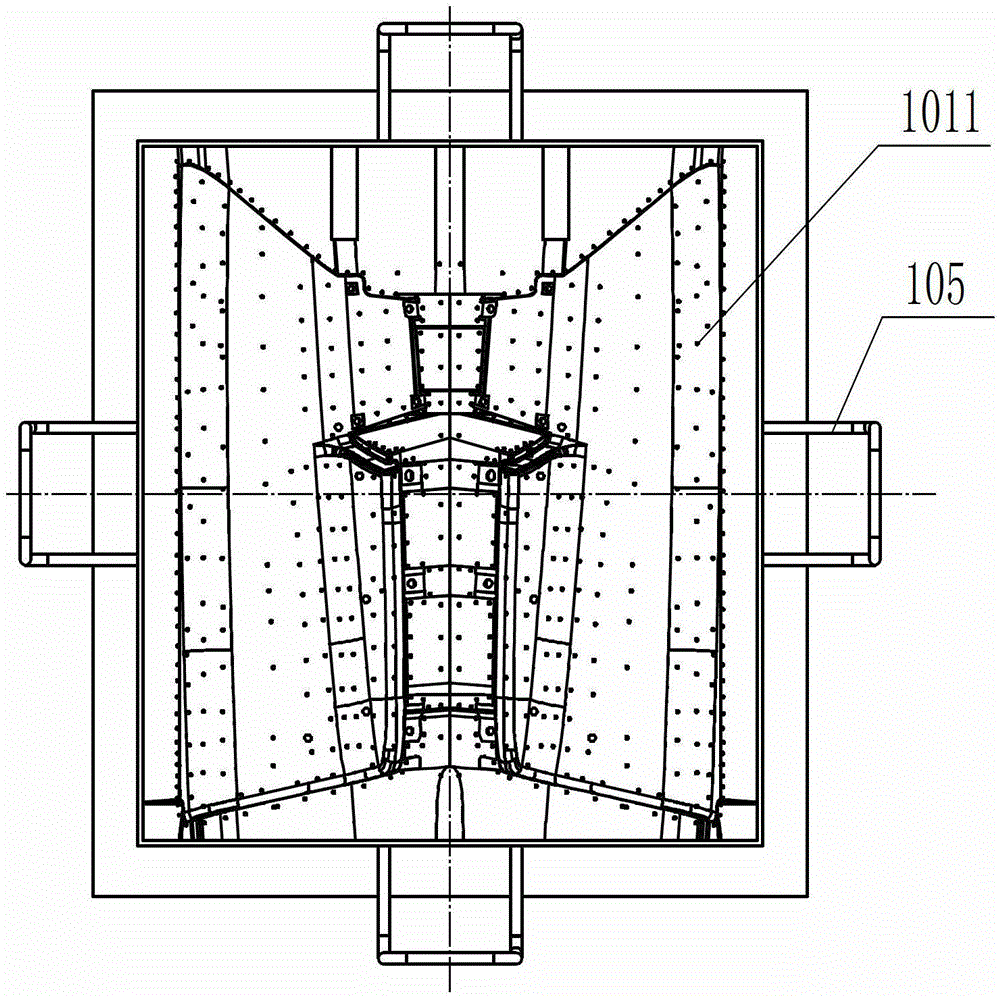

[0063] Place the imit...

Embodiment 2

[0076] A kind of imitation leather process for the surface of the decorative panel in the door panel of a car, the basic steps and the mold used are the same as the first embodiment, but the relevant parameters are different: the step C. The heating temperature during baking is 350° C., and the heating time is set to 42 seconds; step F. The cooling time during cooling is 8 seconds; the diameter of the blister hole is φ1 mm, and the distance between the blister holes is 10 mm.

Embodiment 3

[0078] A kind of imitation leather process for the surface of the decorative panel in the door panel of a car, the basic steps and the mold used are the same as the first embodiment, but the relevant parameters are different: the step C. The heating temperature during baking is 370° C., and the heating time is set to 45 seconds; step F. The cooling time during cooling is 20 seconds; the diameter of the blister hole is φ1.5 mm, and the distance between the blister holes is 18mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com