Flaw detection device and flaw detection method for nonlinear optical crystal

A technology of non-linear optics and flaw detection devices, applied in measuring devices, scientific instruments, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of non-linear optical crystal flaw detection devices, measurement methods, descriptions, etc., and achieve simple and reasonable structure , easy to implement, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

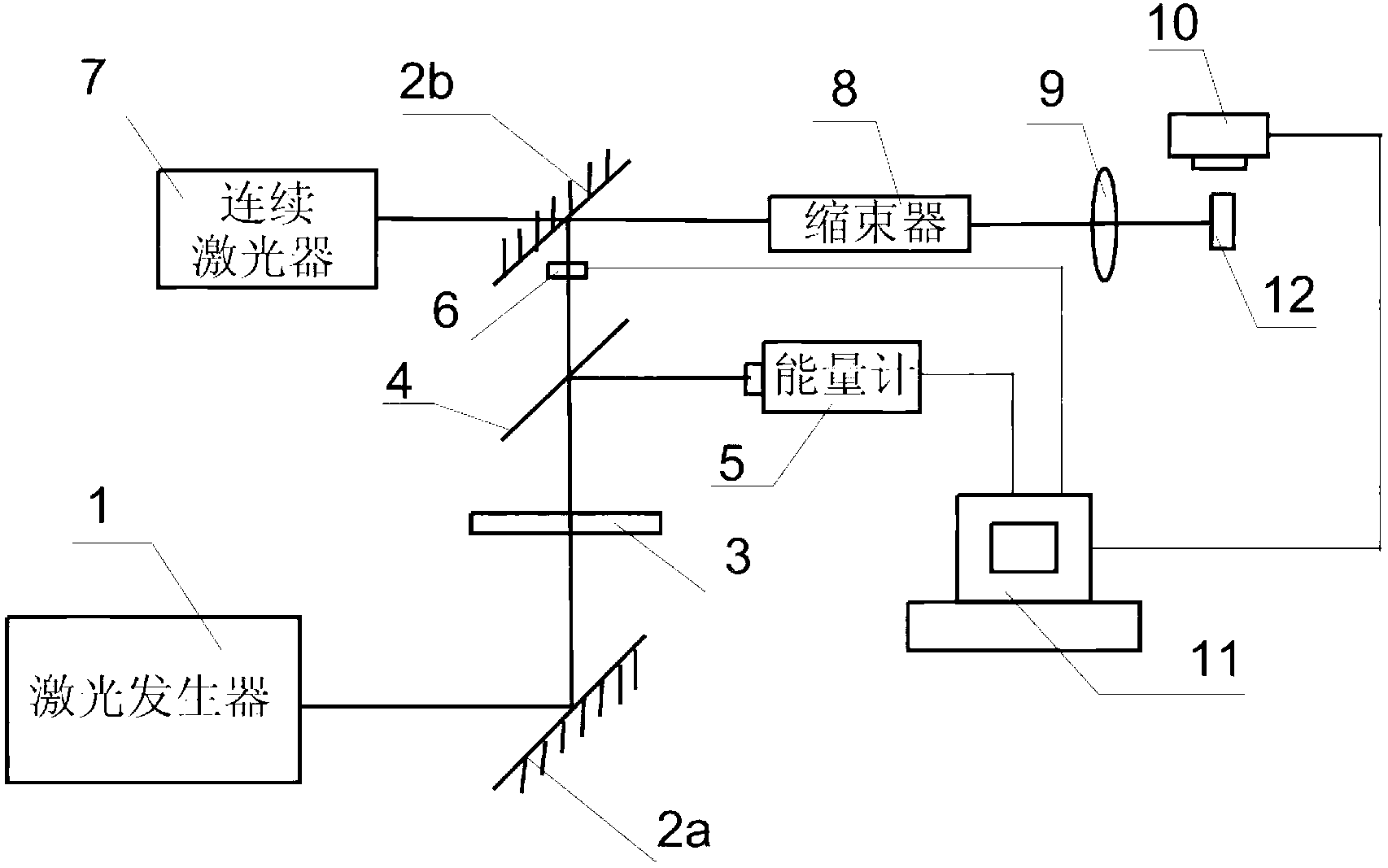

[0043] Such as figure 1 A flaw detection device for nonlinear optical crystal 12 is shown, including a laser generator 1, and the laser generator 1 is used to generate laser light directed to the nonlinear optical crystal 12 to be tested;

[0044] Such as figure 1 As shown, along the light path of the laser generator 1, a first total reflection mirror 2a, a second total reflection mirror 2b, an attenuator 3, a beam splitter 4, an energy meter 5, an optical shutter 6, and a beam reducer are sequentially arranged 8 and converging lens 9.

[0045] The laser generator 1 can adopt a pulsed laser, and the pulsed laser beam sent shoots to the first total reflection mirror 2a, and the laser beam changes the beam direction after passing through the first total reflection mirror 2a, so that it is injected into the attenuator 3, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com