Vane pump cavitation numerical simulation automatic operation method based on ANSYS-CFX software

A technology of automatic operation and numerical simulation, applied in the direction of software simulation/interpretation/simulation, program control device, etc., can solve the problems of reducing vane pump, delay, prolonging the process time of cavitation numerical calculation, avoiding time loss and shortening consumption. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

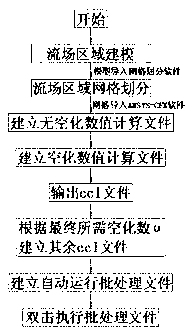

[0023] Centrifugal pump is a kind of vane pump, an automatic operation method of numerical simulation of centrifugal pump cavitation based on ANSYS-CFX software, the steps include:

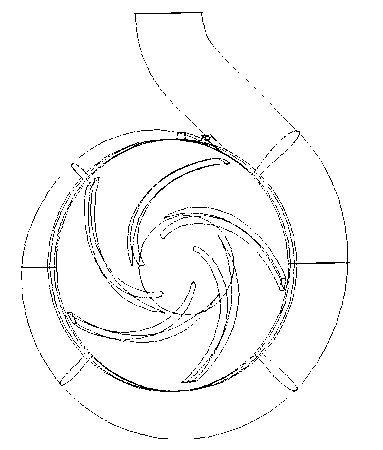

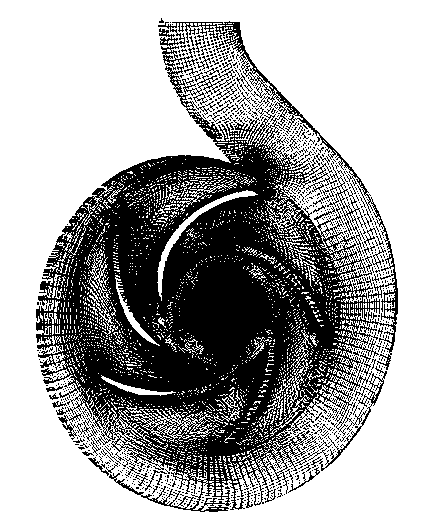

[0024] (1) Use ANSYS-CFX software to set the numerical calculation file of the centrifugal pump without cavitation. Use Pro / E to carry out three-dimensional modeling of the flow field area of the centrifugal pump, including the extension of the inlet and outlet, the impeller and the volute, such as figure 2 Shown; Mesh division software is used to divide the flow field area, such as image 3 As shown; import the grid file into ANSYS-CFX and select the Steady calculation mode; set the liquid phase material water at 25C; adopt the boundary conditions of pressure inlet and mass flow outlet, and set the inlet pressure to 100000Pa; select the turbulence calculation model k-ε; Set the convergence condition 1e-4; output the calculation file pump.def;

[0025](2) Use ANSYS-CFX software to set the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com