Three-dimensional wound iron core three-phase dry-type transformer for nuclear station

A three-dimensional wound iron core, three-phase dry-type technology, applied in the direction of transformer/reactor installation/support/suspension, transformer/inductor coil/winding/connection, etc., can solve the problems of inability to withstand high-intensity vibration and endanger safety, Achieve a high level of safety, ensure complete balance, suppress the effect of harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

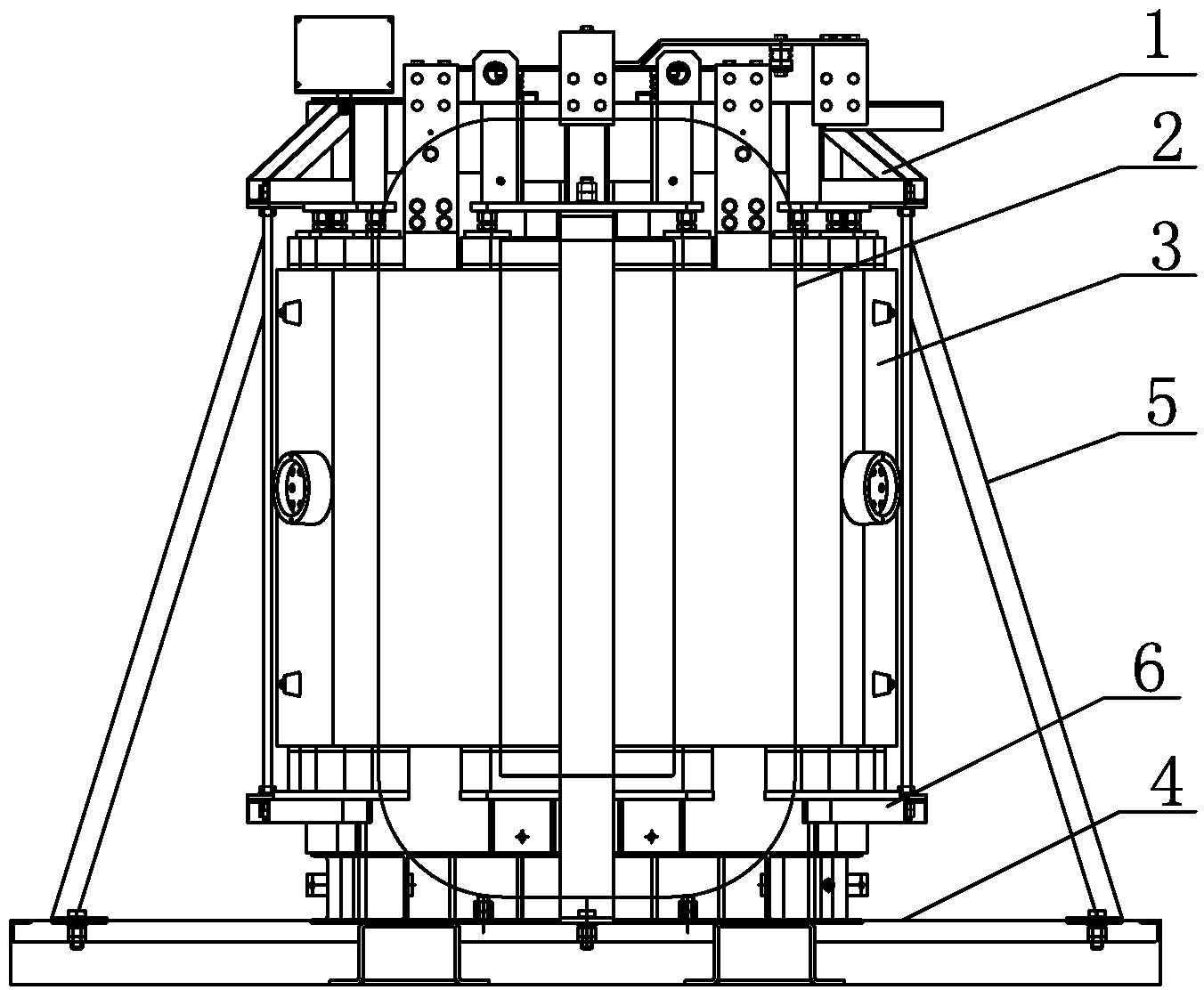

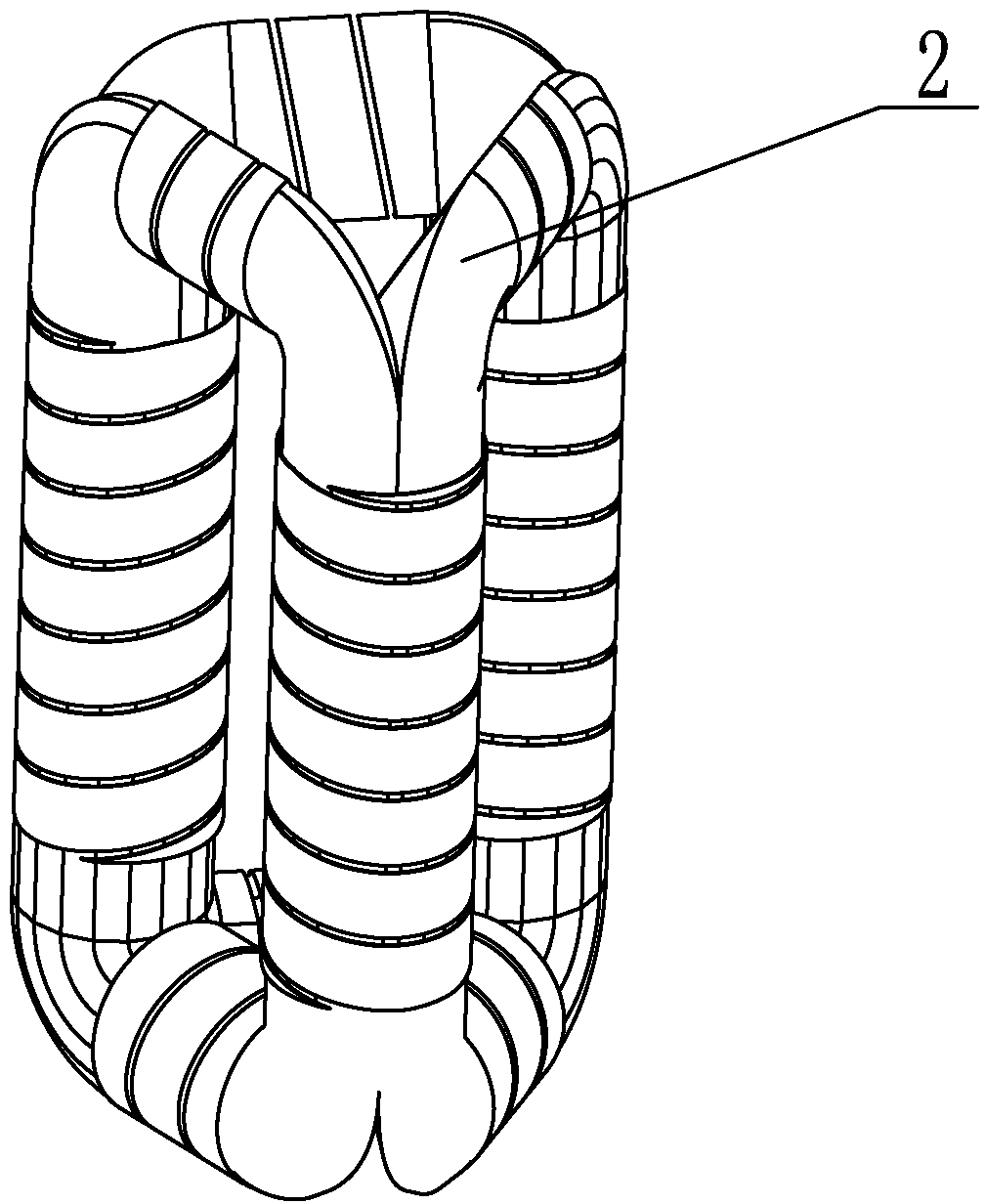

[0014] refer to figure 1 and figure 2 , a three-phase wound core three-phase dry-type transformer for nuclear power plants provided by the present invention is designed for the power supply system of nuclear power transformers. The cores 2 are arranged in a triangle and coils 3 are respectively wound to form a three-phase structure. The clamps include an upper clamp 1 and a lower clamp 6, and the triangular structure of the three-dimensional wound core 2 and the lead wire structure of the coil 3 are connected by the upper and lower clamps. Fixed, because the main body of the transformer itself has a triangular structure, the structure is firm and stable, and it has strong earthquake resistance. The support frame includes a frame base 4 and an anti-seismic support 5. The main body of the transformer is installed and fixed on the frame base 4. The anti-seismic support 5 is erected between the main body of the transformer and the frame base 4. The structure of the three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com