Chip packaging and testing device and lead frame used therefor

A testing device and chip packaging technology, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve problems such as unreasonable design size of the injection channel, waste of lead frame materials, and impact on work efficiency, etc. Achieve the effect of improving parallel testing efficiency, increasing rigidity, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

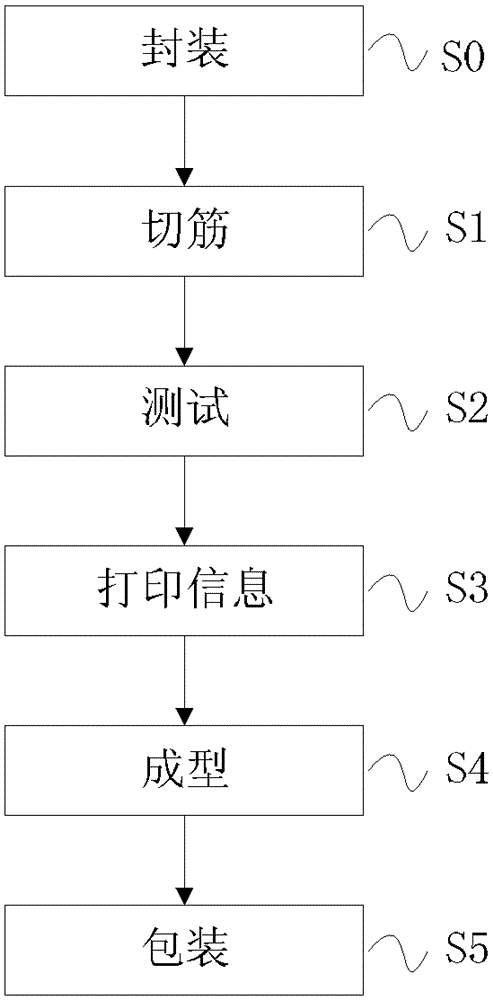

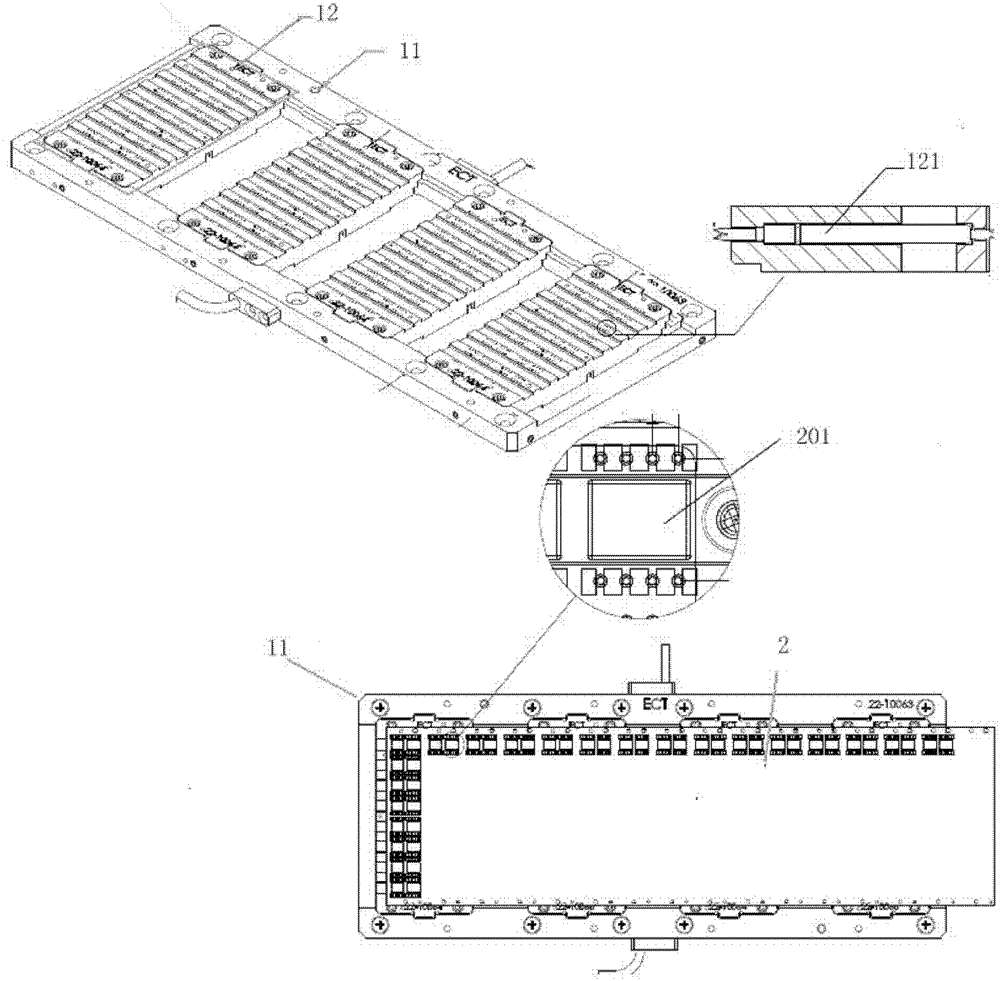

[0034] The present invention optimizes the STRIPTEST test method by developing a chip packaging and testing device with a higher density of packaging units and its dedicated lead frame, that is, it adopts two-dimensional code recognition technology or barcode technology, network technology and database technology, and ensures the smoothness of the test process. Safe, intelligent, and efficient, greatly improving the dependence of testing on manual operation and the potential risk of mixing related to it; at the same time, in order to give full play to the efficiency of the STRIPTEST system, the design of the lead frame is specially improved, and the unit frame is doubled. Density and number of packaged units.

[0035] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

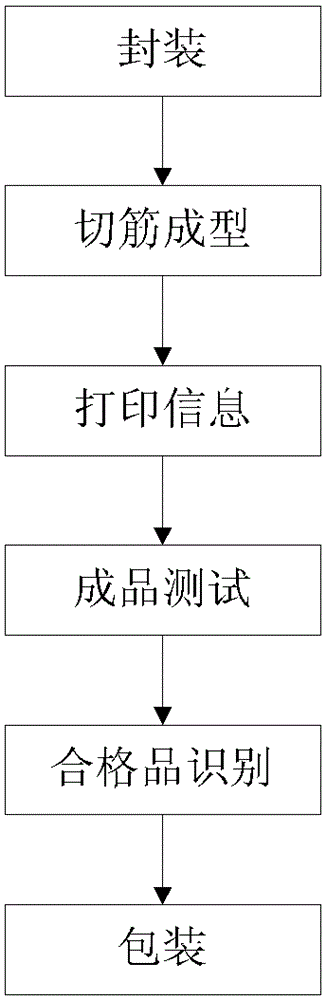

[0036] It should be noted that, compared with the traditional packaging and testing process, STRIPTEST puts more emphasis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com