A series multi-input coupled inductor buck-boost converter

A buck-boost converter and coupled inductor technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems of large volume and weight of the converter, intermittent current at the input and output terminals, low conversion efficiency, etc., and achieve simplification Circuit structure, improvement of dynamic performance, effect of number reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

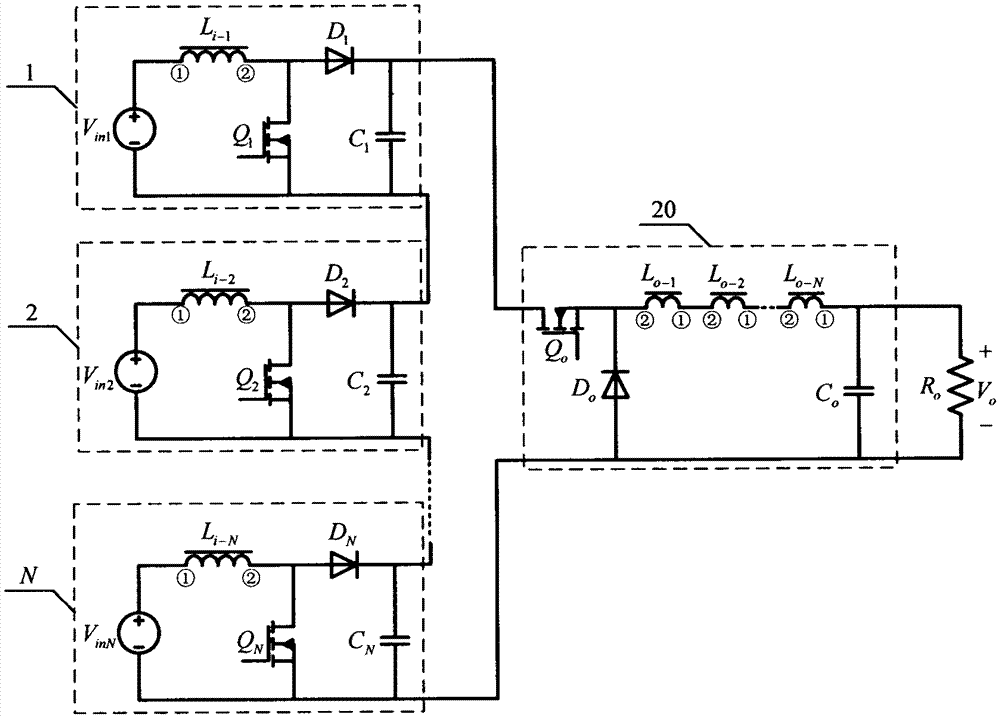

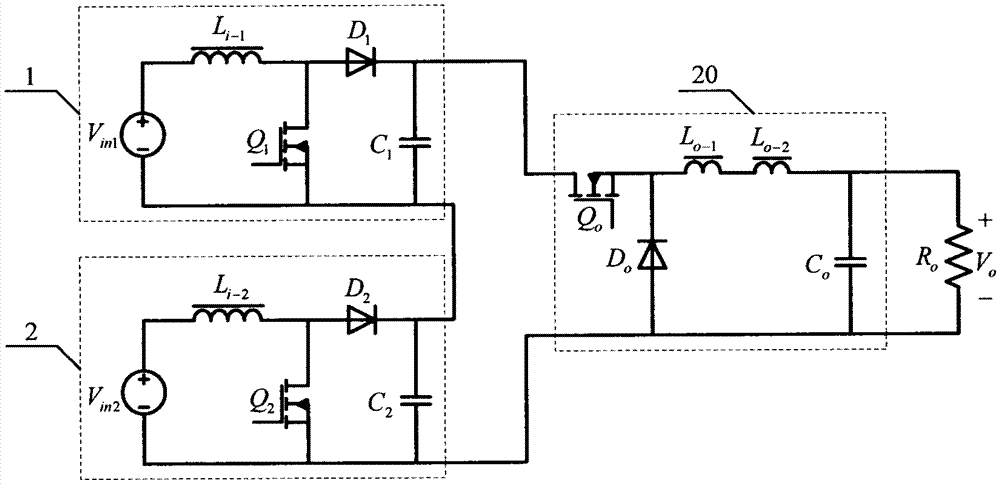

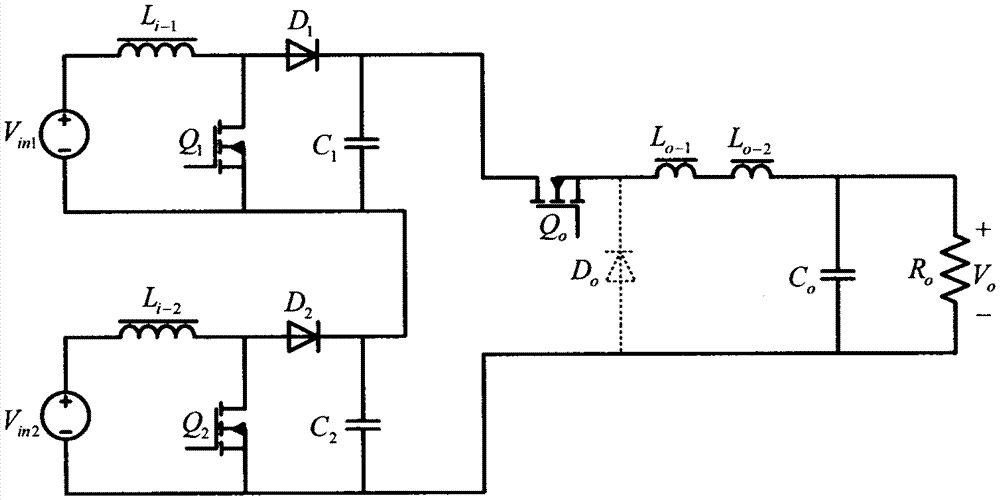

[0020] The present invention adopts the method of cascading the step-up circuit and the step-down circuit to realize the buck-boost conversion between the input source and the load voltage, so as to meet the needs of wide range variation of the input source voltage; Voltage, that is, each boost circuit only needs a lower boost ratio to achieve a higher boost ratio of the entire converter, reducing the difficulty of implementing each boost circuit, reducing the stress of the device, and improving the efficiency of the converter ; By coupling the filter inductors in the boost circuit and the step-down circuit to each other, the number of magnetic components in the converter is reduced, the volume and weight of the converter are reduced, and the mutual coupling between the filter inductors can also cancel each other in the inductance. The high-frequency ripple improves the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com