Lubricating oil composition comprising a blend of friction modifiers

A technology of lubricating oil composition and friction modifier, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., and can solve problems such as concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] The present invention is further described by the following examples, which are not to be construed as limiting the scope of the present invention. The invention can be further understood in the following non-limiting preparations and examples.

Embodiment and

[0093] Synthetic Examples and Preparations:

[0094] In the appended examples all temperatures refer to the degree Celsius system, and the term "room temperature" refers to about 20-25°C. The term "percent or %" refers to wt%, and the term "mole" or "mol" refers to gram mole. The term "equivalent" means that the amount of reactant, expressed in moles, is equal to the previous molar amount of the subsequent reactant described in the described example as a finite mole or a finite weight or volume. Proton nuclear magnetic resonance (NMR) was determined at 300 mHz.

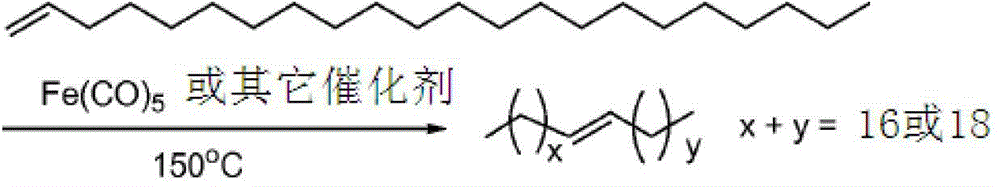

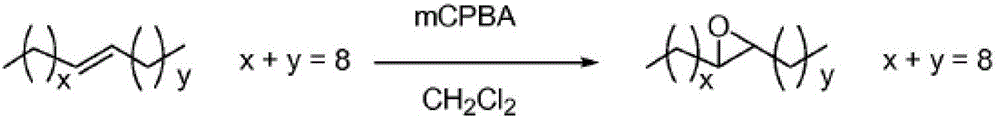

[0095] Olefin Isomerization Step

preparation Embodiment 1

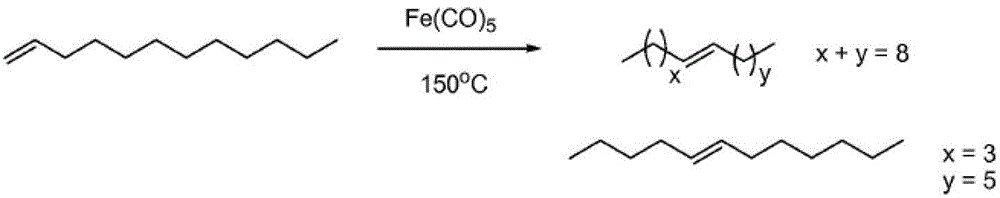

[0096] Preparation Example 1: Isomerization of C12α-Olefins

[0097]

[0098] An alpha-olefin (C12 is used here as an example) is isomerized with iron pentacarbonyl, as a result of the isomerization the double bonds of the starting material (C12 alpha-olefin) are now distributed internally along the carbon chain.

[0099] 180 grams of C12 alpha-olefin were dried overnight under nitrogen over 50 grams of molecular sieves (25 grams of 3A and 25 grams of 4A) and transferred to a 1 L reaction flask. Inject 0.8 mL of Fe(CO) into the flask 5 . The reaction mixture was then heated in an oil bath at 175°C for 4 hours under nitrogen. IR evidenced that the reaction was complete. The oil bath temperature was lowered to 85 °C. 7.5 g of silica gel and 10 drops of methanesulfonic acid were added, and the mixture was stirred overnight. The brown oil in the flask was filtered on a pad of silica and a colorless liquid was obtained as Compound 1. NMR (CDCl 3 )δ5.4(m,2H);2.0(m,4H);1.35(m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com