Grading type combined harvester for potatoes

A combine harvester and grading technology, which is applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of not being put into mass production, high labor intensity, and low production efficiency, so as to meet the requirements of harvesting and smooth grading, The effect of short conveying distance and less damage to potato pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the preferred embodiment shown in the accompanying drawings, further describe in detail:

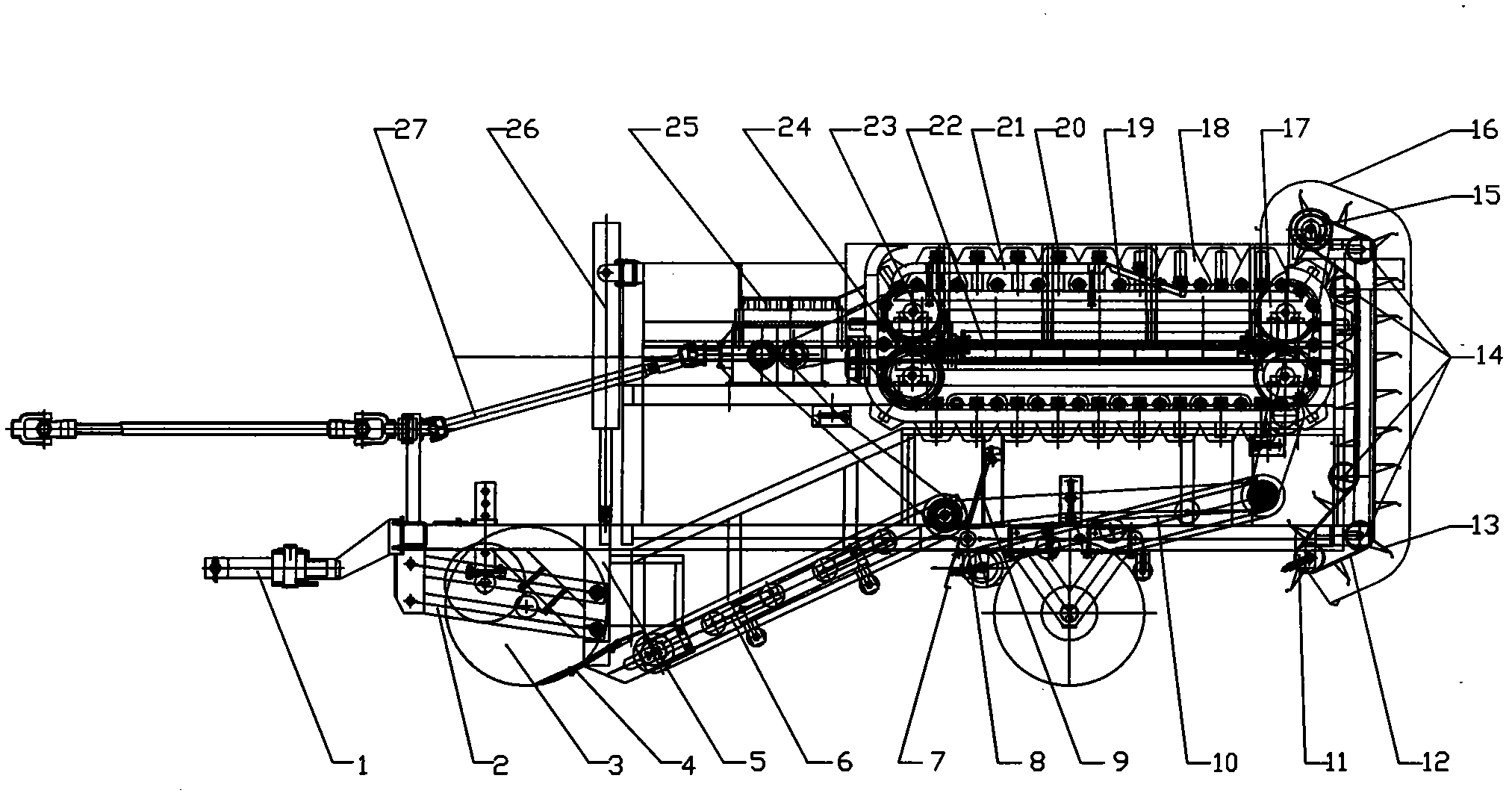

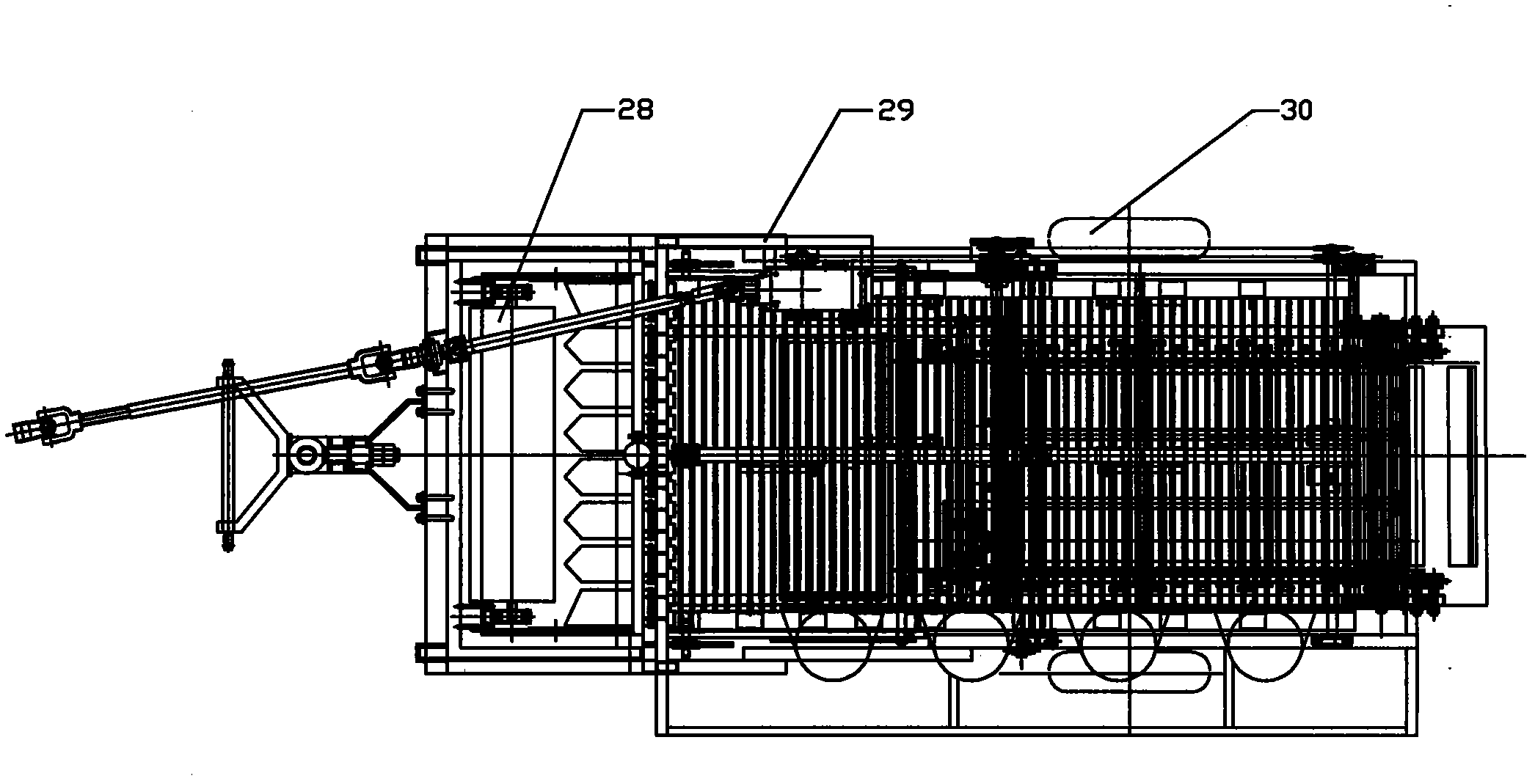

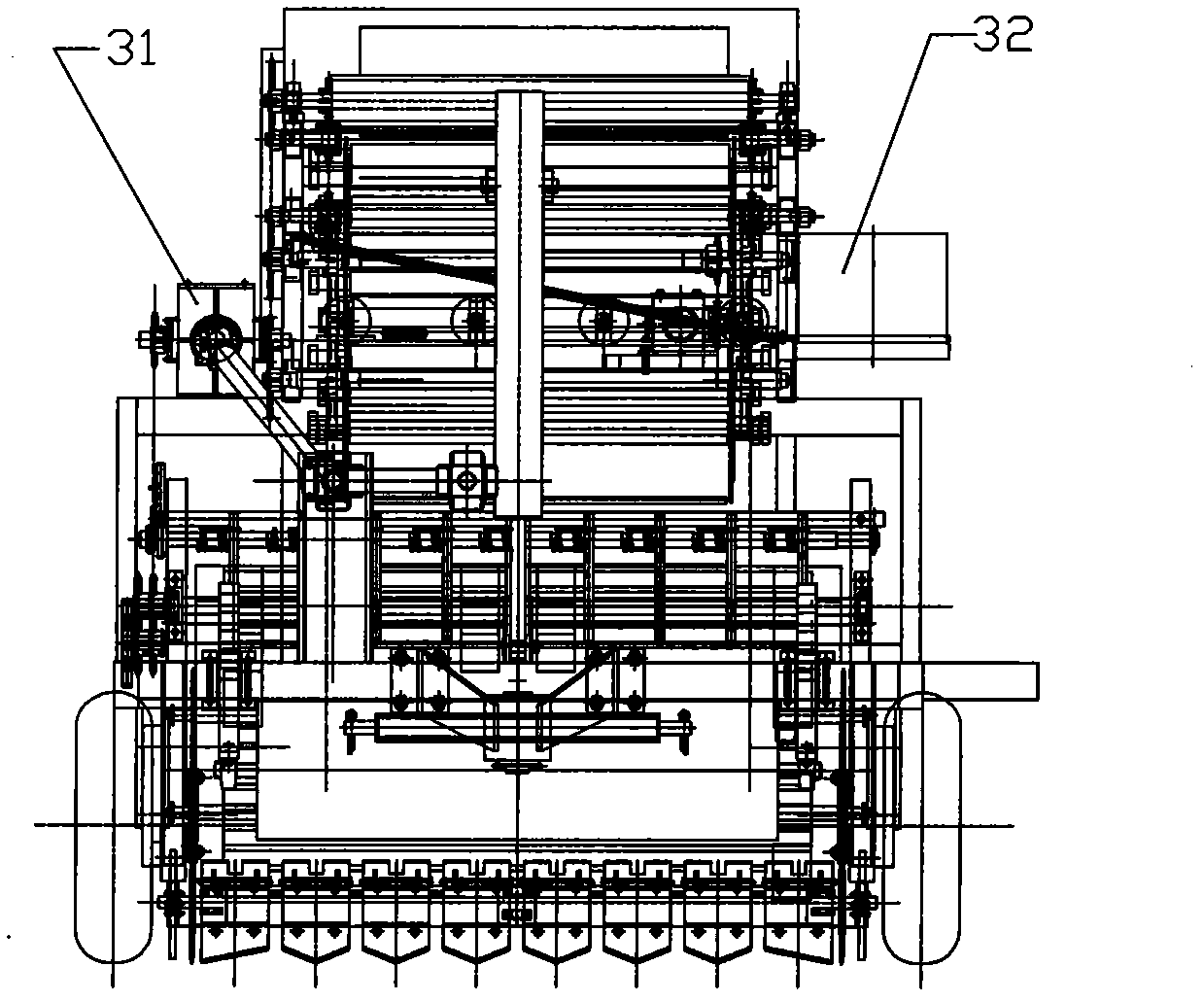

[0015] See figure 1 , 2 , 3, the described graded potato combine harvester, the front end of frame 29 is provided with universal traction device 1, and the complete machine is connected with two pull-down rods of tractor hydraulic suspension device by universal traction device 1, can borrow tractor hydraulic pressure The suspension device regulates the longitudinal horizontal state of the harvester; the frame 29 top is equipped with a lifting cylinder 26, and the piston rod of the lifting cylinder 26 is hinged with the top of the digging bucket frame 5 hinged on the frame 29, so that the harvester is operated in the working state. and the lifting of the digging shovel frame 5 during the non-working state, the profiling suppression roller 28, the soil cutting disc cutter 3, and the digging shovel 4 are installed on the excavation shovel frame 5, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com