Method for improving sun-cured tobacco processing quality

A technology for air-curing tobacco and quality, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large differences in processing characteristics, inability to individualize processing, restricting processing methods, flexible application of process parameters, etc., so as to maintain good quality, The effect of enriching the drying method and removing adverse factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

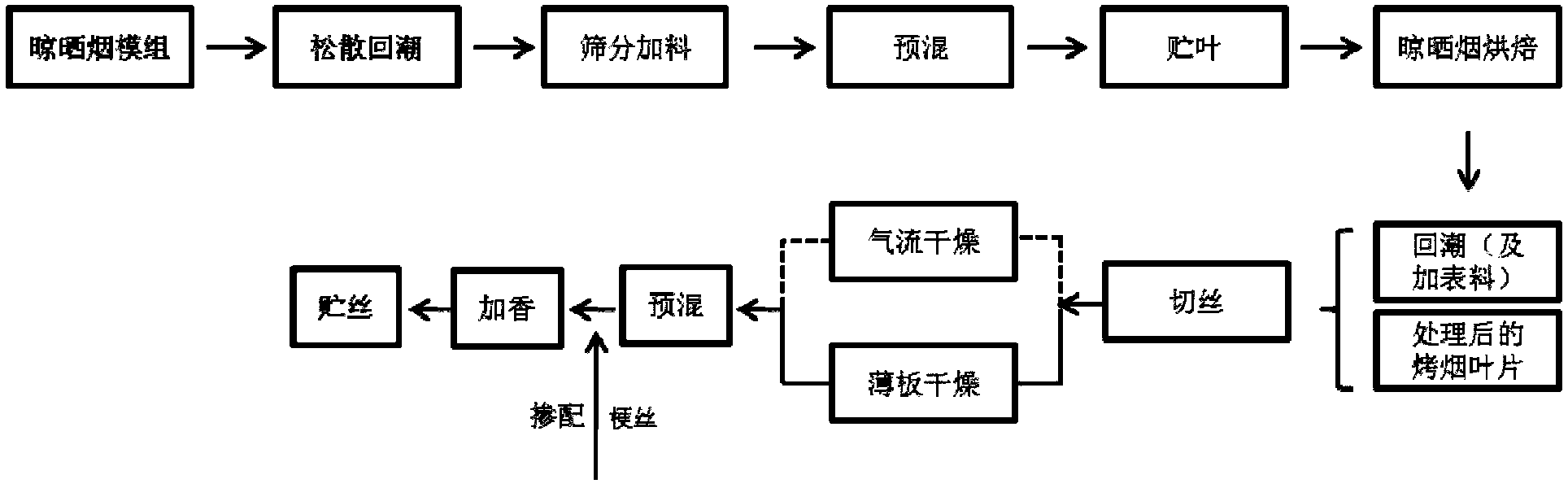

[0034] South China Sun-cured Yellow Tobacco C1F 2000kg, its processing route is as attached figure 2 Shown:

[0035] 1. Drying tobacco drying section, the specific process steps are: (1) Slicing the sun-dried tobacco; (2) Loosening and regaining moisture: the sliced sun-dried tobacco block is heated and humidified in the loosening and dampening drum, and the moisture content of the tobacco sheet is controlled at 16% to 18%, the temperature is controlled at 50°C to 65°C; (3) Sieve the loose tobacco sheets, and then apply feed liquid to the tobacco sheets, so that the moisture content of the leaves is controlled at 19% to 25%, and the leaf temperature Control the temperature at 45°C to 60°C, and the amount of feed is 5% to 10% of the amount of raw materials of sun-cured tobacco; (4) After feeding, the sun-cured tobacco flakes are mixed through a temporary storage cabinet, and then sent to a box for storage to facilitate the absorption of the smoke flakes (5) Send the stored ...

Embodiment 2

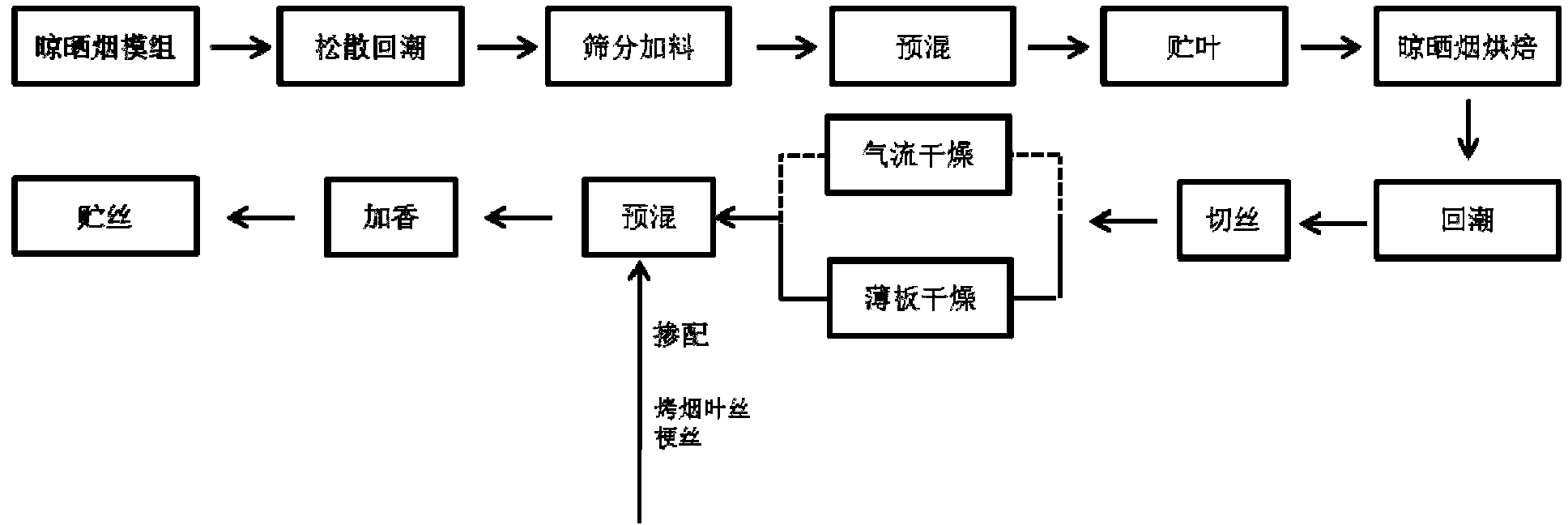

[0042] Baoshan Oriented Tobacco Grade B 2000kg, its processing route is as attached image 3 Shown:

[0043] 1. Drying tobacco drying section, the specific process steps are: (1) Oriented tobacco slices; (2) Loosening and regaining moisture: the sliced oriental tobacco blocks are heated and humidified in the loosening and dampening drum, and the moisture content of the tobacco slices is controlled at 17% to 19%, the temperature is controlled at 50°C to 55°C; (3) Sieve the loose tobacco sheets, and then apply feed liquid to the tobacco sheets, so that the moisture content of the leaves is controlled at 20% to 22%, and the leaf temperature Control the temperature at 45°C to 55°C, and the feeding amount is 5% to 10% of the amount of oriental tobacco materials; (4) After the feeding, the oriental tobacco sheets are mixed through the temporary storage cabinet, and then sent to the box storage to facilitate the absorption of the tobacco sheets (5) Send the stored oriental tobacco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com