Drilling tool for processing annular groove

An annular groove and drill technology, which is used in metal processing equipment, drill repairs, drilling tool accessories, etc., can solve the problems of difficulty in mass production, long cost of laser grooving, and difficulty in mass production, so as to reduce material costs. , The effect of stable processing and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

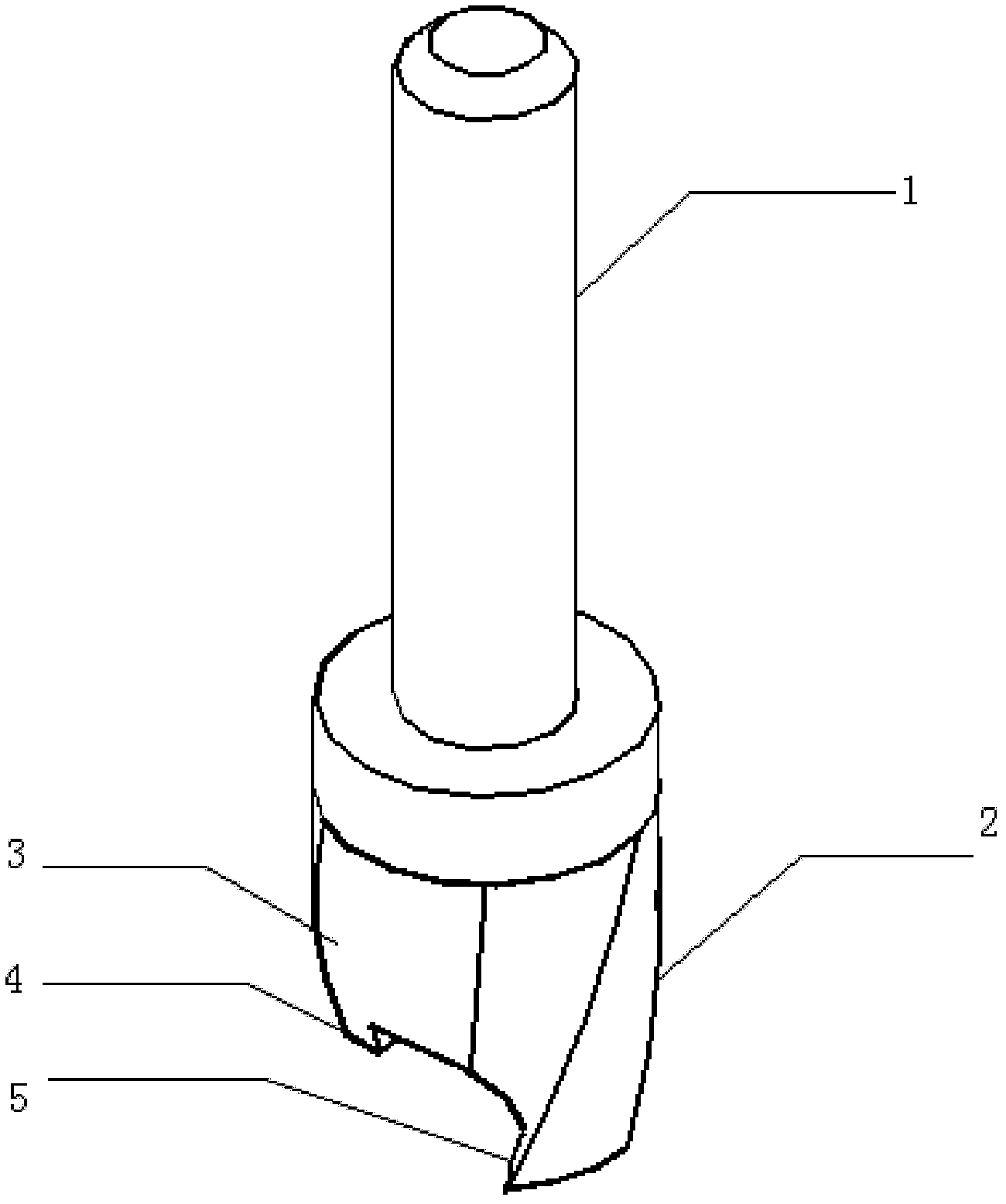

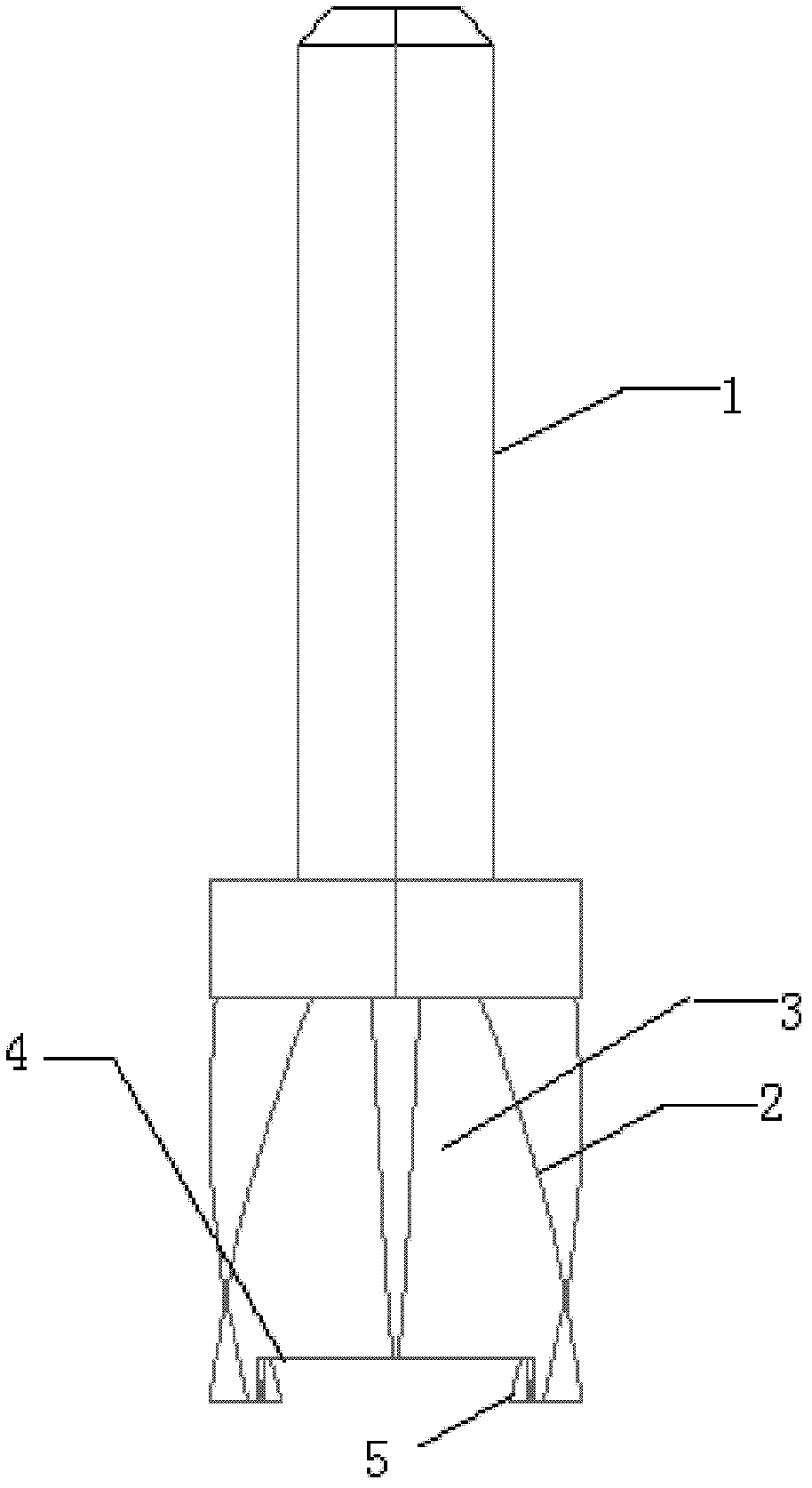

[0020] Such as figure 1 As shown, a drill bit for machining annular grooves includes a tool handle 1 and a cutter head with a rotation angle of 65°. 3. The flute 3 is U-shaped, with an outer blade 2 on its edge, and a cutting groove 4 at the lower end of the cutter head. The cutting groove 4 is arc-shaped, and its side wall is provided with an inner blade 5 and an outer blade 2 It is used to process the outer wall of the annular groove, and the inner blade 5 is used to process the inner wall of the annular groove. The outer blade 2 and the inner blade 5 cut the workpiece along the rotation direction of the drill, and drill annular grooves of different depths according to the thickness of the workpiece. , and the chips generated by cutting are discharged from the chip flute 3.

[0021] The cutter head is made of hard alloy processed into particles, which has high hardness and precision. It can process PCB boards of different materials. It can be processed continuously for more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap